Synopsis: Craftsmen who rely on well-cut joints for their finer projects still find screws handy for reinforcing these joints, as well as for attaching hardware, assembling jigs and bending forms, and making utility furniture, writes George Mustoe. Here, he discusses the basics of how wood screws work, varieties among types, and how wood screws are made. He talks about their mechanical properties and drilling pilot holes – the root of most screwdriving problems. Related articles by Paul Bertorelli and Michael Podmaniczky discuss drywall screws and pilot bits.

One day during my late teens I was struck by the desire to build a small sailboat. The fact that I knew nothing about sailing seemed irrelevant, as did my lack of woodworking expertise. After all, I’d built some barn-lumber shelves for my rock collection just the summer before and, as a foolish adolescent, building a boat didn’t sound much more difficult. Within a year my 12 foot craft was sunk in a spring storm and I have few memories of sailing it, but, fifteen years later, I still remember the blisters I got driving hundreds of screws to fasten the plywood hull. Since then I’ve never had a great fondness for wood screws, but I don’t share the disdain of purists who believe that metal fasteners are the devil’s tool for capturing the souls of cabinetmakers.

Craftsmen who rely on well-cut joints for their finer projects still find screws handy for reinforcing these joints, as well as for attaching hardware, assembling jigs and bending forms, and making the usual run of utility furniture for home and shop (see figure 2, p. 50). Wood screws have gained even greater importance in recent years because of the increased use of particleboard and plywood, materials that are not suited for traditional joinery.

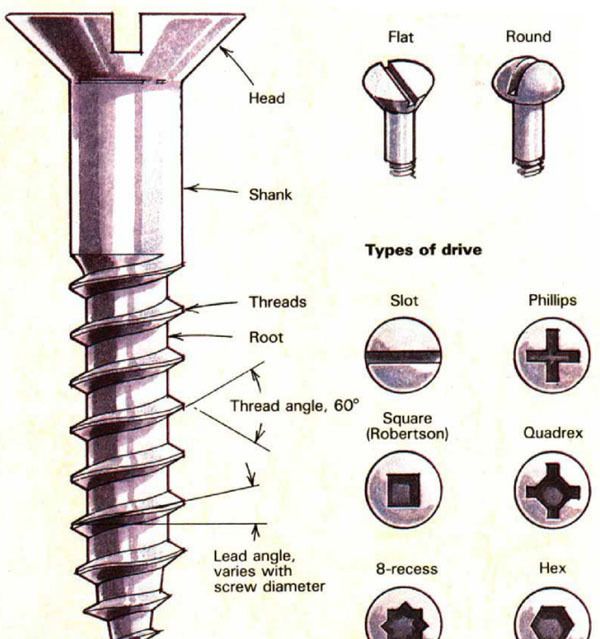

The basic wood screw consists of a head and a shank, roughly two-thirds of which is threaded. Standard wood screws come in lengths from about ¼ in. to 6 in., and a variety of head configurations, as shown in the drawing. In general, flat-head screws are used flush with the surface or hidden beneath a plug. Round-head screws can be left visible, and, for a fancier touch, you can use oval-head screws seated in nickel-plated finishing washers. Sheet metal and drywall screws are increasingly used in wood (see box, p. 51). Sheet metal screws have flat or pan heads and drywall screws employ bugle heads, which are selfcountersinking in sheetrock, most plywood, and softer woods. The drawing also shows some of the variety of drive configurations available. Square-drive screws are common in Canada, where they’re called Robertson screws, after their inventor. A square-drive variant, the Quadrex screw, can be driven with either square or Phillips drivers.

From Fine Woodworking #60

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Bessey EKH Trigger Clamps

Bessey K-Body Parallel-Jaw Clamp

Ridgid R4331 Planer

Log in or create an account to post a comment.

Sign up Log in