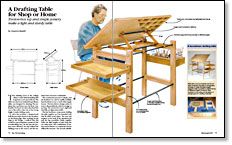

A Drafting Table for Shop or Home

Torsion-box top and simple joinery make a light and sturdy table

Synopsis: Cameron Russell knockdown drafting table makes a good beginner’s project. The table is comfortable to use, and has accessory trays that attach to the legs for easy access. The construction process is simple, and the hardware is readily available. The torsion-box top is rigid and dead flat, yet light and portable. Multiple drawings help show the construction details.

The drafting room at the college where I teach furniture making had long been a sore spot with me. The tables we used were industrial-type library tables, not designed for drawing. The students who used them were far from comfortable. For hours at a time, they hunched over a flat surface that was at the wrong height. It made drafting a pain.

To solve that problem, I designed and built the prototype shown in the top photo on the facing page. After working out the bugs in the design, I realized that this would be a good beginner’s project for the woodworking class. By the time the projects were finished, we had refitted the drafting room at the school, and the students were a lot more comfortable.

The construction process is simple, and the hardware we used is readily available from hardware stores or mail-order supply houses. The knockdown design makes it easy to disassemble the table for storage or moving. The torsion-box top is rigid and dead flat, yet light and portable.

The key hardware components holding the table together are four threaded rods that fit within metal pipes. The nuts and washers on the ends of the threaded rods pull the leg assemblies firmly together while the rigid lengths of pipe keep the two sides apart. This combination of tension and resistance to compressive forces stiffens the structure. The smooth cylindrical surface of the metal pipe also provides an ideal pivot pin for the tilting top.

Torsion-box: light but strong The design for the top guarantees that it will be lightweight, dead flat and strong. The outside skins of 1⁄4-in. plywood are glued to the narrow surfaces of an internal wood frame, and the considerable overall surface area makes a healthy bond. As with any face-to-face gluing of wood, this construction process offers a lot of resistance to twisting forces, making the panel very rigid for its size and weight.

I built this tabletop 24 in. wide by 42 in. long, but the lower structure could easily handle a top up to 30 in. wide by 60 in. long. If you plan to fit a drafting-arm machine or a parallel straightedge to your table, take that size into account when you determine the length of your top.

From Fine Woodworking #123

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Woodriver Rechargeable Desiccant Bag

WoodRiver Router Bit Storage Case

Circle Guide

Log in or create an account to post a comment.

Sign up Log in