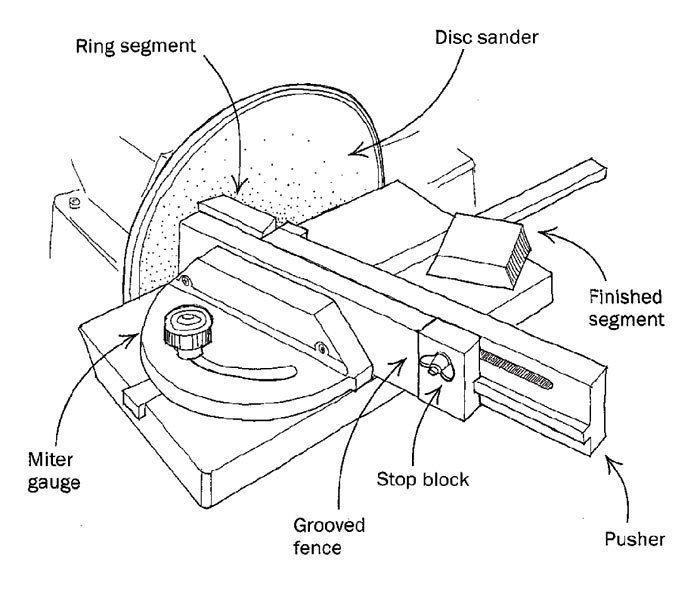

Segmented Turning Blanks on a Disc Sander

I like to turn bowls from ring assemblies that have been laminated from segmented blanks. The problem with building ring assemblies is that any minor discrepancy in the bevel angle or the size of each segment will accumulate into a large gap when you glue them all together. To avoid that problem, I devised this jig, which ensures that each segment is exactly the same.

You can make the jig from any close-grained hardwood. It consists of three simple parts: a grooved fence that attaches to the miter gauge; a pusher that slides along the fence; and a stop block.

To use the jig, first miter the segments on a tablesaw to a rough size and angle. Allow about 1/16 in. extra in length. Scribble pencil marks on the miters of all of the segments and then with the miter gauge set at the correct bevel angle sand one end of all of the segments on the disc sander until the pencil marks disappear. Find the shortest segment and sand the remaining end miter of this segment to produce a master. Use the master to set the stop block on the jig and tighten the wing nut to lock it into place. One by one, place the remaining segments against the fence and sand the other ends, sliding the segment into the sander until the pusher hits the stop block. All segments should now be the same length and be beveled at the same angle.

Bob Deacon, Gorleston-on-sea, Norfolk, England

Fine Woodworking Magazine, August 2001 No. 150

Fine Woodworking Recommended Products

CrushGrind Pepper Mill Mechanism

Woodriver Circle Cutting Jig

MicroJig Matchfit dovetail clamps

Log in or create an account to post a comment.

Sign up Log in