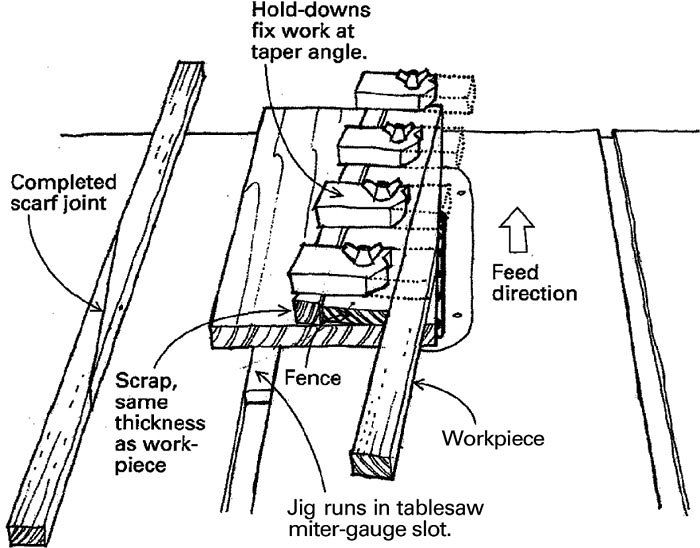

Table Saw Jig for Making Scarf Joints

The scarf joint, which joins stock lengthwise without loss of strength, deserves more recognition outside its traditional domain of wooden boatbuilding. Here’s how I make the joint for other woodworking projects.

Make a tablesaw jig from a scrap of 1/2-in. plywood, about 8 in. wide by 32 in. long. Attach a runner to the bottom of the jig to ride in the miter-gauge slot. Trim the edge of the jig with a pass through the sawblade. Now attach a 5/8-in.-high fence angled to the blade at 5¡ (a slope of 12:1). Install four or five hold-downs with machine bolts and wing nuts, as shown.

To use the jig, locate the piece to be scarfed tightly against the fence, and clamp with the hold-downs. Support the left side of the hold-downs with a piece of material the same thickness as the workpiece. With the sawblade set slightly deeper than the material to be cut, make a pass through the saw.

To keep the joint parts in registration during glue-up, drill a small hole through the splice, and drive in a small round dowel or bamboo skewer.

William R. Fuller, Dewitt, N.Y.

Fine Woodworking Magazine, February 1996 No. 116

Fine Woodworking Recommended Products

Veritas Wheel Marking Gauge

Dustopper Pro

Stanley Powerlock 16-ft. tape measure

Log in or create an account to post a comment.

Sign up Log in