Bandsaw mills are more affordable than ever

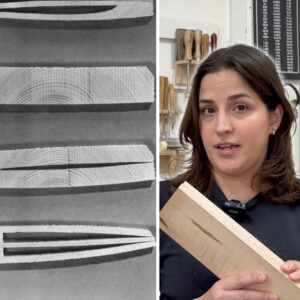

Michael Fortune's new Woodland Mills HM126 bandsaw mill can turn raw logs into beautiful boards.

The latest addition to Michael Fortune’s woodworking homestead, in rural Canada near Toronto, is a portable bandsaw mill which will let him saw his own lumber from the log. After seeing the Woodland Mills HM126 in action at a local demo, he was surprised to see a sticker price under $3,000, meaning the machine would pay for itself in a few years.

But watching him fire it up on a snowy day, I got the sense that owning this machine is at least half about the fun of it all. Fortune didn’t stop at the basic equipment, of course, but made it permanent on a concrete platform, with a timber platform alongside for rolling logs aboard. Walking behind the bandsaw carriage, Fortune rolled it smoothly through a 2-ft.-thick walnut log, exposing the creamy interior and grinning the whole time.

Soon after, Fortune built a solar drying kiln from framing materials and clear plastic roof sheathing, to handle the green lumber he produces. The temperatures inside hit 100 on a 25-degree day. A small computer fan keeps the air moving.

More from FineWoodworking.com:

- Video: Using a Portable Bandsaw Mill

- Video: From Log to Lumber

- Lumber from Your Own Backyard

- Mill Lumber Safely

Comments

Not sure what " few years means "

What's payback,period and cost reality / assumptions on wood type , quantity , value assigned to fuel and labour .?

Love the idea but few years ! Give us a break .

I don't own a mill, but have had trees on my property milled. It's a great way to reduce lumber costs. Michael will quickly discover that the kiln he's built is woefully too small, though. It's amazing how much wood can come from a few trees! I wouldn't get my wood any other way.

I purchesed a norwood lumber mate in 2000. I now have many thousand board feet stashed in three barns I n addition to the second floor of my shop. Milling your own lumber is extremely satisfying and addictive. I live in the Amish country here in pa. So there are many drying kilns that dry my lumber at a very reasonable cost.

Dswoodshed.com

Apparently you (redpen) haven't purchased any Walnut lumber lately. In my area "rough sawn" Walnut sells for over $5/bdft with thicker lumber (2-3") going for north of $10 bdft. So, if Michael was sawing a 10' length of 2' in diameter Walnut a week, he would have his investment back in less than a month, two months at the outside.

This is a seductive avocation. I have two years intermittent experience with a >$1500 Lumber Smith that I'm using to mill timbers for my yet-to-be-built off-grid post-and-beam workshop. It's so much fun that I find myself fantasizing about live-edge slabs, cants and board-and-batten siding . . .

I live about an hour away from Mr Fortune and have the exact same mill. I have mounted it on a trailer to do portable milling. I milled only 4-5 logs and got approx. 300 bd/ft of black cherry and maple last winter (2013-14) At an average cost of $4.00 per bd ft that's $1200.00. Minus the $150 I spent for the logs and fuel and labour adding another 50 bucks, I got a third of my money back from only 5 logs. And as mentioned in the article I had a blast doing it. Can't wait to see what furniture it turns into.

The first time I ever saw a bandsaw mill in action was in 2004. I made a promise to myself that I would own one someday. And then I found plans to build one on the internet. I began a long process of buying parts here and there when I had a few extra dollars (meanwhile putting two kids through college, keeping my business doors open and various other fund-draining activities). Then two years ago I finally started welding, building, rebuilding and testing. Today I am proud to say I have a working bandsaw mill that does an excellent job of turning logs into timber. My friends ask how much time and money I have in it. If you count the hours I've spent building and the cost of time and material, I certainly could have bought and paid for a really nice mill. But I have the satisfaction of knowing I did it. And yes, it is addicting to saw open a log and see the wonderous grain God created on the inside!

Sawing your own lumber is addictive indeed. I hire a local sawyer with a portable mill to cut trees on my PA plot. My $200 solar kiln holds about 450 bf. I can easily dry 2000 bf in a year and have not bought a board in a store for 10 years. No matter how much I have spent, it was repaid in enjoyment revealing what lies beneath the bark of a log. Hauling logs is the most expensive part, an aspect that pains me when I see logs that could be had for nothing but still cost too much to have hauled for milling.

How quickly the machine pays for itself depends on how much wood you use. As a working pro, Fortune builds constantly, so his payoff will come quicker. Of course, there is the joy of expanding your woodworking journey to include the log-to-lumber leg. There is something amazing about starting with the tree itself, and taking it all the way through to that last coat of shellac.

Log in or create an account to post a comment.

Sign up Log in