STL 153: Setting up shop with Justin Fink

Fine Homebuilding editor Justin Fink comes in to discuss shop heating, moving a post, shop floors, walling in utilities, and all time favorite shops of all timeThis episode is brought to you by Fine Home Building and their Keep Craft Alive initiative.

06:47 – Question 1:

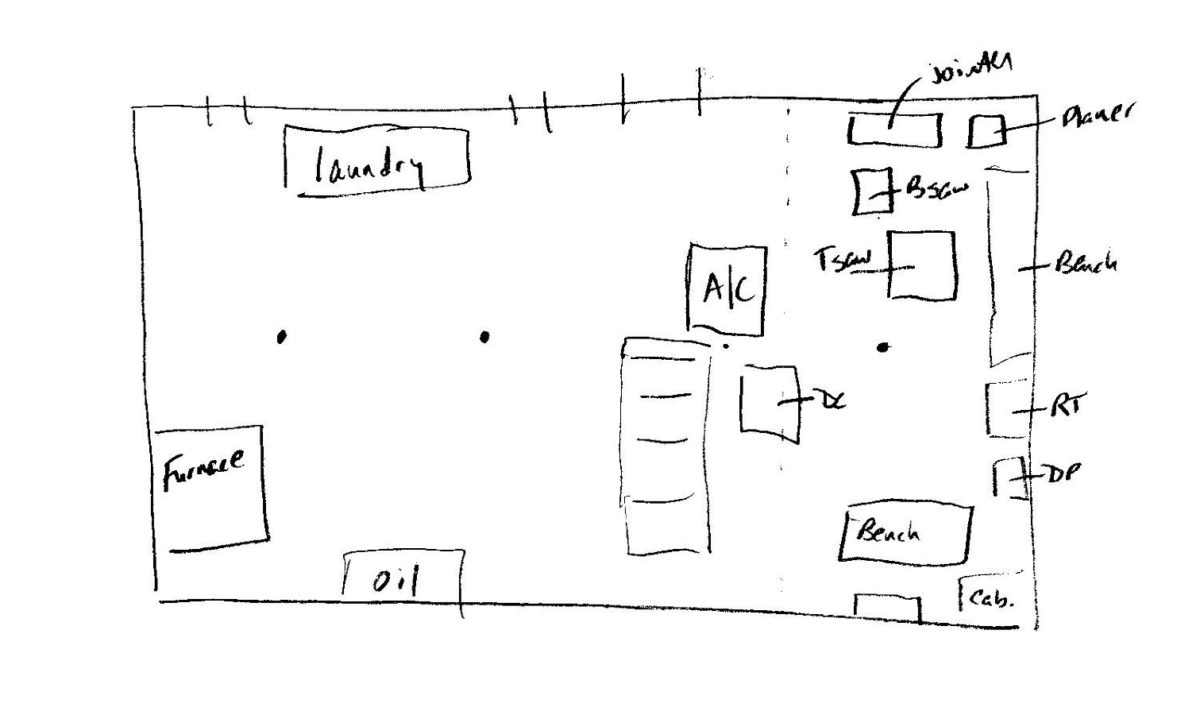

My shop is in the basement, and I’d like a little separation between it and my utilities. If I walled off the furnace and water heater, how much breathing room do I need to leave? Also, Ben is the best. -Tom McKenna

16:41 – Question 2:

We rent our house, and my wood shop occupies my half of the garage. This is our first winter here and I’m not sure how to properly heat the garage. Given this is a rental, a heat pump or gas heater that requires ventilation is kind of out of the question. I do have a table saw that runs on 220, so I could use that circuit if needed. What type of heating unit would you recommend? -Peter

30:22 – Question 3:

I have a two-car garage with a 4×6 post pretty much dead center. There is a bedroom wall above the post running from the back of the garage about 2/3 of the way to the front. What would be the easiest way to support the wall above and get rid of this post? -Bruce

Video: How to Install a Load-Bearing Beam

40:25 – All-time favorite workshop of all time… for this week

Justin – A wide open timber-frame structure

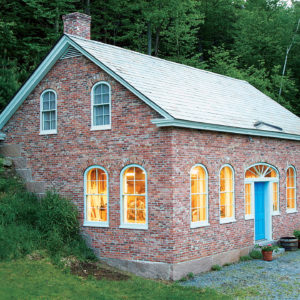

Mike – Charles Durfee’s shop in Maine

|

|

Tom – Garrett Hack’s shop in Vermont

|

|

Ben – Dave Fisher’s shop in Northwest Pennsylvania

|

|

54:06 – Question 4:

I am about to build a 1,200 sq-ft. shop and would like to know your thoughts on what you consider to be the optimal floor considering I have some heavy machines. Also, given the chance would you run the dust collection under the floor or go with the more common ducting overhead? -Tom

PROHOME 2017 – Foundation Insulation Strategy

|

|

|

| Tom McKenna Editorial Director |

Mike Pekovich Creative Director |

Ben Strano Web Producer |

Every two weeks, a team of Fine Woodworking staffers answers questions from readers on Shop Talk Live, Fine Woodworking‘s biweekly podcast. Send your woodworking questions to shoptalk@taunton.com for consideration in the regular broadcast! Our continued existence relies upon listener support. So if you enjoy the show, be sure to leave us a five-star rating and maybe even a nice comment on our iTunes page.

Comments

An excellent follow up to the last podcast. Great idea to bring in Justin Fink to get a builder’s perspective. Like Justin, I can’t stress enough about creating comfort in the shop. Not only to protect iron/steel surfaces but also as a means to be more motivated to spend more time in the shop.

A big thumbs up to Ben for pointing out the advantages in having a shop space attached to the home! I’d rather build a detached garage than give up my attached woodshop (a converted two car garage).

Not only does my attached shop get me in the shop more, it brings my whole family to the shop. Even when friend said drop by, we typically spend the majority of time in the shop.

I’d like to point out that shop comfort has more forms than just heat and insulation too. Lighting is a consideration that is much discussed but often overlooked. In converting my 24x24 garage, I added four windows and an half glass exterior entry door for natural light. I removed the single 16 foot overhead door and replaced it with two 9 foot overhead doors which I open in the summer for even more natural light. I installed 12 incandescent lights and have been slowly replacing those with outlets for 24” linear LED fixtures (2-4 per previous lamp holder). The modularity of the LEDs is very budget friendly. Aside from that, I have two very comfortable rolling office chairs that I salvaged from the trash. I see many wood shops with just a wooden stool or two but the comfort level of my adjustable height, rolling, reclining leather high back executive chairs are really where it’s at for comfort. And, they were free. For fully maximizing time in the shop, I installed an outdated flat screen television which is wired to my over the air antenna (mainly to watch football) as well as to an old surround sound system (for music) and a cheap android tv box (for YouTube, Spotify and podcasts). Lastly, I installed another half glass exterior grade door that leads into the house. This further increases connectivity to my home. My wife and kids can peek in on me working in the shop without disturbing me (if,say, I’m using the tablesaw and need to concentrate). Also, since the attachment to my shop is via the mud room, it allows me to easily monitor the comings and going of my house. I see many attached shops that just have a plain steel door and I gotta shake my head that they don’t know what they are missing over a relatively simple upgrade.

Thanks for the show. I hope my comments here inspire someone like your show inspires and informs me.

Gr

Very helpful episode, as I'm planning a shop. I wonder what the tradeoffs are between Justin's floor, with two layers OSB "floating" on foam, vs. Mike's floor (and the one in the 3rd description link) that one layer thicker OSB on sleepers. I would expect Justin's floor to have advantages in vapor and insulation performance. Would the sleeper approach have mechanical advantages?

I'm 70 and my Grand Dad was 73 when he died and I was seventeen. My Grand Dad was considered a Master carpenter who learned his trade as a ship's carpenter where he did his appreniship. He considered himself a carpenter. He had the biggest collection of wood working hand tools that I have ever seen. His idea of carpentry was to do it all. I never heard of him refer to a difference between carpenter and woodworker A master carpenter did it all. From framing to finish to furniture to cabinetry to carving. there was no differentiating between. His only limit was to do everything with hand tools, nothing power at all.

Just said as a difference in the times, not as a criticism.

Love your show.

Log in or create an account to post a comment.

Sign up Log in