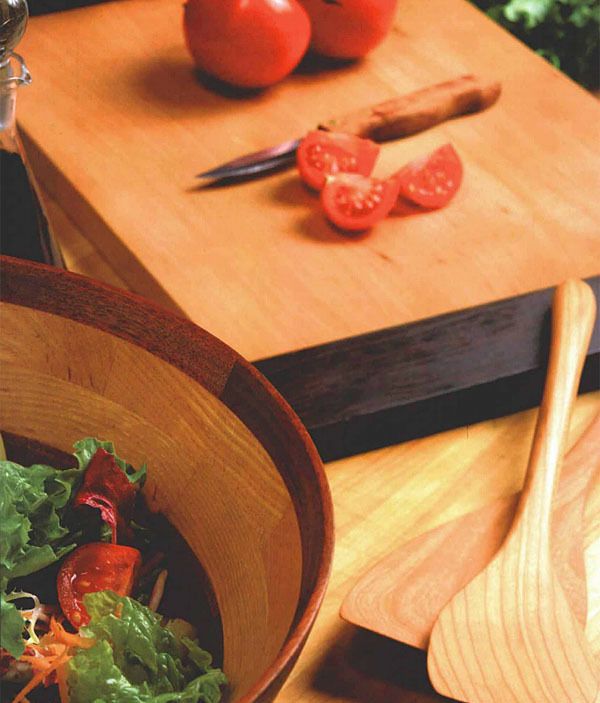

Wood finishes that are food safe

A summary of non-toxic finishing products ideal for cutting boards, salad bowls, and other food-centric woodwork

After scores of conversations with chemists, regulatory agencies, finish manufacturers, finishing experts, and woodworkers, I found that there are a few finishes that everyone agrees are food safe. However, these food safe wood finishes (sometimes called cutting board finishes) tend to be the least protective, and the great majority are in a kind of limbo, with many experts saying most are fine for use with food but with others saying they should be avoided because there are some lingering questions about their safety. In the welter of contrary opinions about which finishes are food safe and which are not, a few naturally derived, unblended, no-hidden-ingredients, certainly nontoxic finishes stand out.

Pure tung oil. Extracted from the nut of the china wood tree. Used as a base in many blended finishes. Available from catalogs and hardware stores. Difficult to apply, requires many coats, good water-resistance.

Raw linseed oil. Pressed from flax seeds. Not to be confused with boiled linseed, which contains metallic driers. Listed as a food additive by the Food and Drug Administration (FDA). Very long curing time, good looks, low water-resistance, frequent reapplication.

Mineral oil. Although derived from petroleum, it is colorless, odorless, tasteless and entirely inert. Sold as a laxative in drug stores and as a wood finish in hardware and kitchen-supply stores. Simple to apply, low water resistance, frequent reapplication.

Walnut oil. Pressed from the nuts of the walnut tree. Sold as a salad oil in health food stores and in large grocery stores. Walnut oil dries and won’t go rancid. Easy to apply, frequent reapplication.

Beeswax. The work of the honey bee. Can be mixed with an oil to create a better-smelling, slightly more water repellent finish. Sold in woodworking and turning catalogs.

Carnauba wax. Derived from the Brazilian palm tree. Harder than beeswax and more water-resistant. Can be used straight on woodenware as a light protective coating or a topcoat polish. Sold in woodworking and turning catalogs.

Shellac. A secretion from the lac bug. Harvested in India. Super blond shellac in flake form is the most water resistant variety. A film-forming finish. Sold in woodworking catalogs and hardware and art supply stores.

Greenwoodworker David Fisher discusses a variety of food-safe finishes and their individual characteristics in relation to color enhancement, drying capabilities, and curing agents to help inform your project decisions.

A recipe for one sweet finish

The food-safe finish that appeals most to me is one recommended by Jim and Jean Lakiotes, West Virginia makers of spoons and other kitchen items, as well as furniture. Their finish is a mixture of mineral oil and beeswax.

To make it, warm the mineral oil in a saucepan over low heat, and melt a chunk of beeswax in it equal to about one-fifth or one-sixth the volume of the oil. (At high heat, there’s a potential for fire. Be sure to keep the heat low, and consider using a double boiler.) As the wax begins to flake apart and dissolve, stir frequently. When the mixture is blended, pour it into a jar to cool and solidify.

To apply, wipe on an excess of the soft paste, let it dry a bit, then wipe it off. If you want to apply it as a liquid, you can reheat it. Like any mineral oil or

wax finish that will take a lot of abuse, this one will need to be reapplied often to afford decent moisture protection. But applying this fragrant finish is such a pleasure that you may find yourself looking forward to the task.

This article is excerpted from Jonathan Binzen’s article “Which Finishes Are Food Safe,” featured in Fine Woodworking #129.

More from FineWoodworking.com:

Fine Woodworking Recommended Products

Bahco 6-Inch Card Scraper

Odie's Oil

Bumblechutes Bee’Nooba Wax

Comments

What wold happen if you added some tung oil to the beeswax and mineral oil mix? Seems like it would add a nice color..

Could one finish a cutting board lets say with 3-4 coats of Shellac and then rub beeswax with 4-0 steel wool? Wouldn't it be far more durable than just an oil finish?

Log in or create an account to post a comment.

Sign up Log in