How to bandsaw your own veneer

Tips for smooth slicing in any kind of wood

Synopsis: Shop-sawn veneer offers the stability of commercial veneer and a measure of flexibility that is missing from its commercial cousin. The bandsaw is the essential veneer tool, but make sure it’s tuned properly. Timothy Coleman explains how to tune and set it up your bandsaw to resaw veneer, and how to prepare and cut the plank into slices. He shows how to surface the sheets of veneer in several ways and then how to use the veneer in your projects. The article offers tips for aligning your bandsaw to the blade’s drift. A pictorial of complicated veneer projects will spur you on.

From Fine Woodworking #143

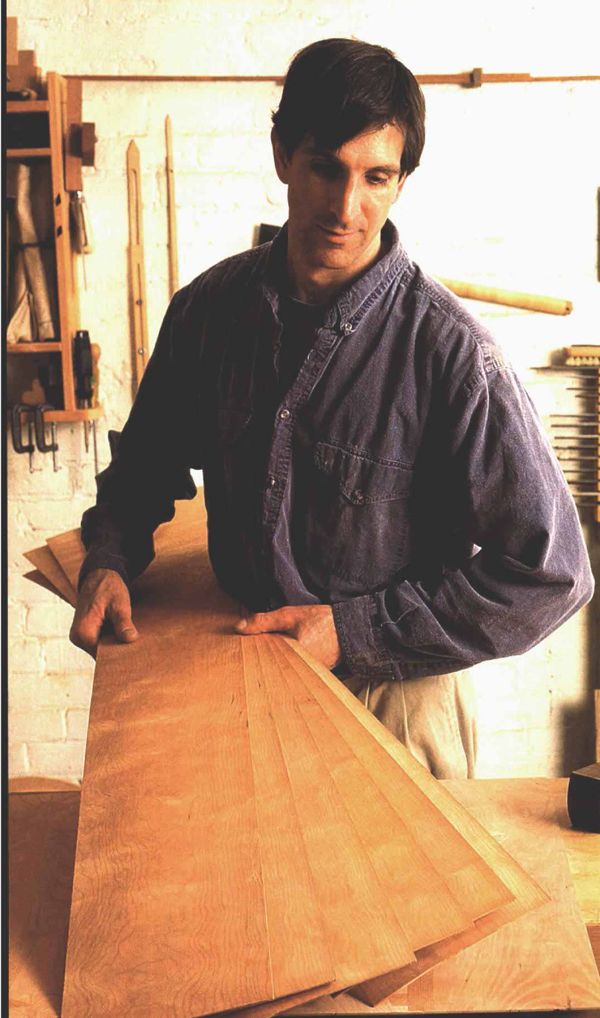

It is a wonder to me that I can take a piece of solid wood, with its unforgiving properties of seasonal movement, resaw it into veneer and glue it to a stable substrate, and it will suddenly behave quite demurely. Much of my work consists of decorative cabinets and tables, and on the broad surfaces of these pieces veneer really shines. Most often, I cut my own veneer. Shop-sawn veneer gives me the stability of commercial veneer and a measure of flexibility that is missing from its commercial cousin. It lets me mix solid wood and veneer from the same stock, offers more integrity on an exposed edge and has enough thickness that I can work the surface as if it were solid wood. I can handplane the material or do shallow carving or sculpting on the surface. Building with solid wood may be faster than using bandsawn veneer, but I can seldom resist the magic of sawing a board into thin slices and spreading it out over the surface s o f a piece of furniture. There are times when I use commercial veneer . Th e exotic figure and wide dimensions of the material can be an advantage. In recent years, however, the standard thickness of commercial veneer has gotten thinner and thinner. There is no margin for error when working with this material, and I am on pins and needles until the piece has a finish on it . When I saw solid stock in- to veneer myself, I have no such worries .

Bandsaw: the essential veneer tool

At the heart of sawing your own veneer is the bandsaw. If yours is running correctly, cutting veneer will be a pleasure. If not, prepare for pain. I have spent many hours fine-tuning my bandsaw. I have replaced the tires on the wheels, replaced the original guides with Carter roller-bearing guides and modified the factory-supplied fence so that it can pivot a few degrees, which allows me to adjust for the drift of the blade. Just about any bandsaw carefully tuned can be used for sawing veneer. I use a 24-in . European saw, and it works very well . A smaller saw will work, but its limitation will be in the width of the stock it will cut. If needed, you can always rip the plank into narrower pieces, resaw it an d rejoin the veneers edge to edge. I typically use silicon-carbide hook-tooth blades, ½ in. or ¾ in. wide. The teeth are set in a raker pattern, which means the y alternate left, right, left, right and then have an unset raker tooth . Bimetal blades reportedly work well on abrasive woods . However, because the y are designed for cutting metal at slower speeds and are more than twice the price of standard blades, I do not use them.

To view the entire article, please click the View PDF button below.

Fine Woodworking Recommended Products

AnchorSeal Log and Lumber End-Grain Sealer

Starrett 12-in. combination square

DeWalt 735X Planer

Log in or create an account to post a comment.

Sign up Log in