How to Resaw on the Bandsaw

Make thin boards safely, easily, and with little waste

Synopsis: You can move beyond the standard lumber dimensions and open a wealth of design options by learning to resaw thick stock on the bandsaw. For instance, you can slice a board in half to create book-matched panels; you can slice extrathin stock for dividers and delicate boxes; and you can cut your own veneers to get the most from a prized plank of figured wood. Contributing editor Lonnie Bird explains the steps necessary to resaw successfully: Start with the right blade; adjust the table and guides; add a tall fence to support wide stock. Included are tips for slicing long stock or thin veneers.

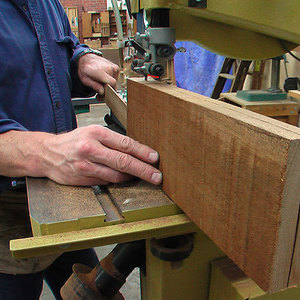

Resawing thick stock on the bandsaw to create thinner lumber or veneer offers a variety of benefits to woodworkers. It not only allows you to move beyond the standard lumber dimensions available at lumberyards and home centers, but it also opens all sorts of design options. For instance, you can slice a board in half to create book-matched panels; you can slice extra thin stock for dividers and delicate boxes; and you can cut your own veneers to get the most from a prized plank of figured wood.

Yet, with all the benefits resawing offers, few machine techniques seem as difficult to master. Because the blade is embedded along the width of the wood, resawing places a lot of demands on both the bandsaw and the blade. If the saw isn’t powerful enough or the blade isn’t sharp enough, the blade can buckle and bow, the motor can bog down and stall, or the blade can wander out of the cut and spoil the workpiece. But with the right setup, you’ll overcome these obstacles and achieve uniform, flat cuts every time.

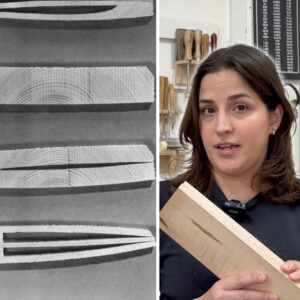

Probably no factor affects your success as much as blade selection. I find a coarse, narrow blade with a positive rake angle (the angle at the front of the tooth) works best. For most resawing, I’d use a hook-tooth blade with 2 tpi to 3 tpi, 3⁄8 in. to 1⁄2 in. wide and 0.025 in. thick. This coarse blade effectively pulls sawdust out of the kerf, allowing the blade to run cooler and thus cut faster. The positive rake angle pulls the wood forward, making it easy to feed with a light touch. The only downside of such a coarse blade is that the cut will be somewhat rough and prone to vibration, so it may not be suitable for resawing thin veneers, which are spoiled easily. If you plan to resaw veneers from thicker stock, you may want to use a variable-tooth, hook-type blade. The teeth on this blade are the same shape but vary in size, which results in less vibration.

Ready the bandsaw for resawing

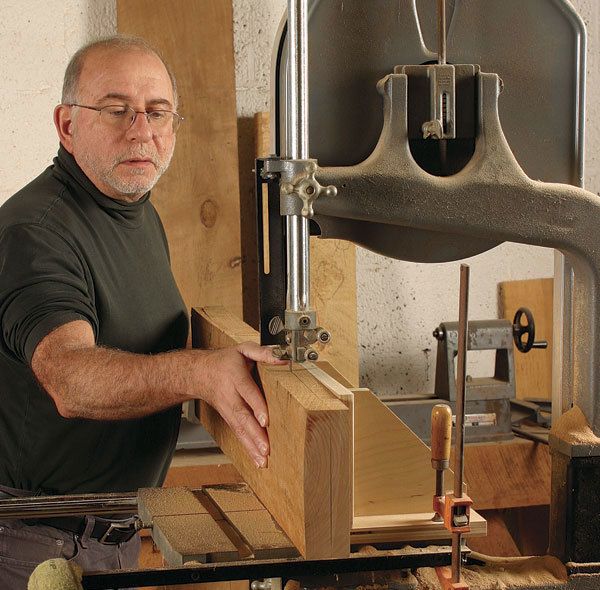

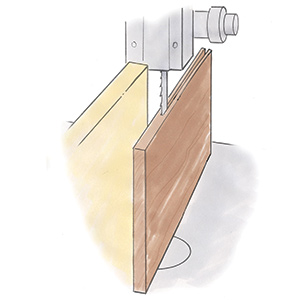

Not only does resawing require the proper blade, but for consistent results and smooth cuts, it’s also critical to adjust the bandsaw. These adjustments must be made in the proper sequence. First mount, track, and tension the blade; then square the table to the blade and adjust the guides. Finally, if the fence on the machine is too short to support wide stock, build an auxiliary fence. Because resawing generates a lot of dust, use dust collection at the source as well as an ambient air cleaner.

From Fine Woodworking #189

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Freud Super Dado Saw Blade Set 8" x 5/8" Bore

JessEm Mite-R Excel II Miter Gauge

Shop Fox W1826

Log in or create an account to post a comment.

Sign up Log in