All About Lap Joints

Learn how to cut half-laps, center laps, and lap miters.

The lap joint comes in a number of styles and applications, but each follows the same general principle: Two parts are cut to overlap.

The Basics:

• Half-lap: Remove the full width of each intersecting member, but only half of the thickness

• Center lap: A half-lap that’s fully housed.

• Lap miter: The portion removed from each joining piece is triangular.

Half-lap

If you were building a cabinet or sideboard with a face frame that intersected at the corners, you might use a half-lap joint. On this joint you remove the full width of each intersecting member, but only half of the thickness. The assembled pieces are then equal to the full thickness of the material.

This joint is rarely used in furniture construction because without glue or a fastener (screw or nail), it cannot remain intact. Often the half-lap is employed to register parts in knock-down applications.

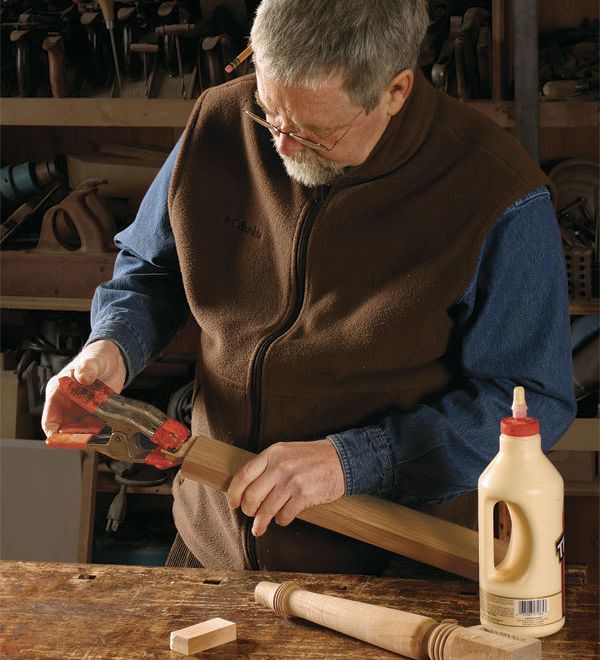

Depending on the size, the half-lap can be cut on the tablesaw using compound cuts (two perpendicular cuts with a combination blade), with a dado head (on the tablesaw), or on a router table. Sometimes the shoulder cut is made on the tablesaw and the cheek cut is done on the bandsaw.

Center lap

This variation on the half-lap is cut the same way (remove the full width of each intersecting member, but only half the thickness). However, because each half is fully housed, the joint is much stronger. The center lap is often employed on large face frames for furniture and cabinets, and on architectural millwork.

The center lap can be cut on either the tablesaw or with a router. If the tablesaw with a dado head is used, the bottom of the cut may not be smooth. If a smooth-bottomed cut is necessary, use a router with a large-diameter, straight bit.

Lap miter

This is another variation on the lap joint, except that the portion removed from each half is triangular. This reduces the long grain surface, but produces a visible mitered corner. From the outside edge, the half-lap is visible. From the front, the joint presents a mitered corner. It’s a reasonable compromise for the required effort; providing adequate strength and an attractive appearance. It’s also a way to align and secure the miter; preventing the two parts from slipping out of position when gluing up.

This joint can be cut on the tablesaw using a compound cut. However, each of the two cuts would require a dedicated jig or a special setup. It could also be produced with a router.

More Joinery Articles from FineWoodworking:

- All About Dovetails

- All About Miters

- All About Dados and Rabbets

- All About Spline Joints

- All About Tongue-and-Groove Joints

- All About Mortise and Tenons

- All About Box Joints

- All About Butt Joints

- All About Dowels and Biscuits

- All About Breadboard Ends

- All About Specialty Joints

Fine Woodworking Recommended Products

Leigh D4R Pro

Olfa Knife

Freud Super Dado Saw Blade Set 8" x 5/8" Bore

Log in or create an account to post a comment.

Sign up Log in