Carving tool tune-up

With keenly honed tools, you'll sharpen your skills as a carver

Synopsis: Carver Ian Agrell tells his students to treat sharpening as an art in itself. More important than the choice of sharpening system is knowing what shape is required for a carving tool’s edge. Outside and internal bevels and the angle of the cutting edge relative to the tool’s shank all have a vital bearing on how well it will behave in wood. Agrell recommends a 10° degree inside and outside bevel and says all tools require an edge that’s square to the shaft. Chisels are the easiest to sharpen, while gouges require a smooth, rotating technique and V-parting tools require the most patience. He also adds a word about maintaining and storing carving tools.

Learning to sharpen carving tools takes time, patience and practice, much like carving. I tell my students to treat sharpening as an art in itself. Of course, the real joy comes when they use a wonderfully sharp tool, which doesn’t just cut wood but leaves the surface beautifully burnished—shiny, smooth, without any nicks or scratches.

There are a great variety of sharpening materials available—all manner of electric grinders, natural and man-made stones and honing compounds. I hold no brief for any particular machine or stones. More important than the choice of sharpening system is knowing what shape is required for a carving tool’s edge. Outside and internal bevels and the angle of the cutting edge relative to the tool’s shank all have a vital bearing on how well the tool will behave in wood. I recommend that most tools be honed with inside and outside bevels of about 10°.

Now this isn’t rocket science, so a degree or two off won’t blast your carving skills out of orbit. But aim for consistency. Later on you may wish to experiment with different angles to see what suits your style of work, and you may indeed find that changing some angles will be advantageous.

All tools require an edge that’s square to the shaft

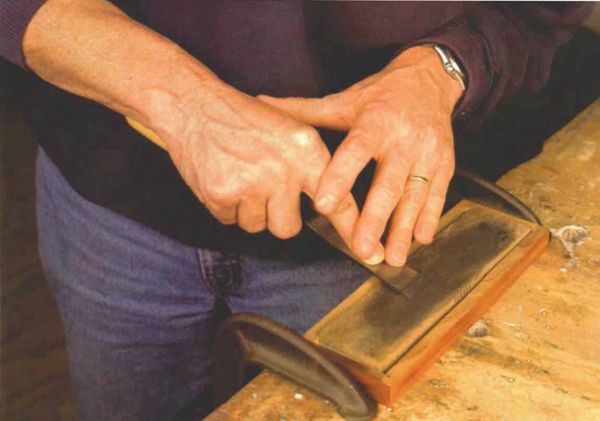

Sharpening by hand is of course the traditional method for getting a good edge. If you’re a beginner, this method can be instructive because you can see the tool’s edge taking shape, albeit slowly. It’s easy to make corrections without removing too much metal or overheating the tool, which can destroy its temper.

There are two basic steps to sharpening carving tools. First, you have to shape the edge of the tool relative to the shaft. Second, you must hone and strop the bevel(s).

Most carving tools work best with a cutting edge that is square to the shaft. If the corners or wings are rounded, you cannot get the entire cutting edge to arrive at the same depth when setting in (cutting down into the ground of a carving). Or, if you try to slide the edge of a rounded gouge into a small corner to remove wood, the nose or tip of the tool will get in the way. You will also have problems if the nose of the blade is ground away more than the wings. Skew chisels, whose blades are purposely angled, are the only exception.

A blade is easily squared by holding the tool vertically and dragging it back and forth over a coarse stone. Don’t worry about the bevel now; just square the cutting edge relative to the shank.

From Fine Woodworking #133

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Bahco 6-Inch Card Scraper

Suizan Japanese Pull Saw

Veritas Precision Square

Log in or create an account to post a comment.

Sign up Log in