Understanding Wood Movement

Proven methods for dealing with expansion and contraction

Synopsis: Wood is a living, breathing material, and as a result it moves. Learning why and where it moves will help you become a better furniture maker. In this article, Christian Becksvoort demystifies wood movement and details different construction methods that allow for movement over the life of a piece, including frame-and-panel construction, breadboard ends, and mortise-and-tenon joinery. He describes trouble points in multiple furniture projects and tells you how to tackle issues in each. Tips for fitting doors and doors, attaching headboards, and applying molding are explained.

From Fine Woodworking #165

For centuries, granite has been quarried along the Maine coast. Way back in the woods behind my shop, on a granite outcropping, sit a few leftover slabs 10 in. thick by 2 ft. wide by 12 ft. long. The granite faces show a series of 1⁄2-in. holes drilled 12 in. to 18 in. apart. The old-timers would have driven dried wood into these holes, then walked down the row pouring water onto the wood. Eventually, the granite slabs would split apart. When wood cells absorb water, they swell and expand, and not even granite can stop it. So forget about pins, glue, screws, or fancy joinery; wood will move and break apart your work if you don’t follow the rules.

The exact amount of wood movement depends on any combination of several factors, including the environment (the degree to which humidity fluctuates) and how the lumber has been sawn.

The amount of movement also varies among wood species, particularly among the hardwoods. For example, beech, hickory, oak, and hard maple move substantially more than cherry, walnut, and butternut.

Last, the type of finish you apply to a piece affects wood movement. Because light skin finishes such as wax and oil allow greater moisture absorption, wood that has been coated with either of them moves more than wood that has been finished with deeper-penetrating sealants such as urethane and lacquer.

As a professional woodworker, I can’t afford to cut corners when it comes to wood movement. So I devote my energy to building furniture right the first time—whether it’s a chest, a case, a bed, or a table.

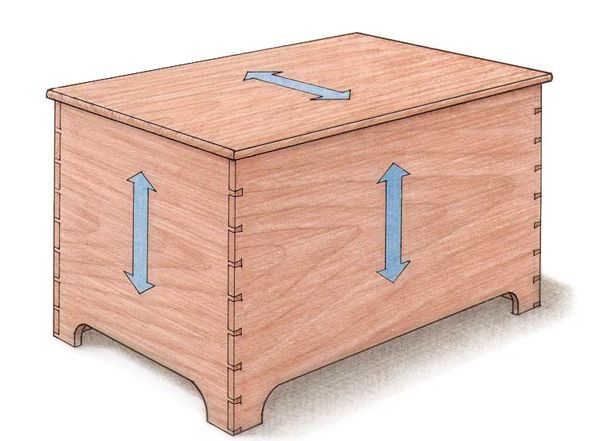

A blanket chest, in which the grain runs in a band around the entire box, is an example of slab construction. The depth and width of the chest remain constant, because the wood does not move lengthwise. But the wood does change in height in response to changes in humidity. The blanket chest gets slightly taller in summer and shorter in winter. Because movement in the top is from front to back, the hasps of the lock don’t always fit. The solution is to use quartersawn wood for the top, file the hasp parts to increase clearance, and use a good sealing finish.

For the full article, download the PDF below.

Fine Woodworking Recommended Products

Bessey EKH Trigger Clamps

Festool DF 500 Q-Set Domino Joiner

Dubuque Clamp Works Bar Clamps - 4 pack

Log in or create an account to post a comment.

Sign up Log in