Below I’ve attached a video showing how the lowboy is constructed piece-by-piece. I’ve taken advantage of the SketchUp capability to reposition the axes on components. When right-clicking on the component, you can choose an option for changing the axis location. It is helpful when the new axis location is coincident with a common connection point.

Here is a picture of the completed lowboy.

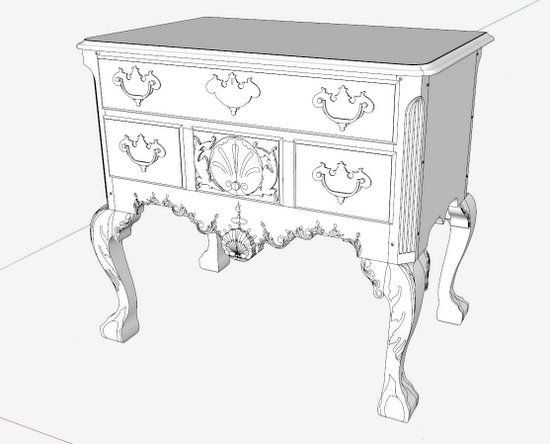

And here is the SketchUp model.

Note that I did not do 3D contoured carving in the SketchUp model. Rather I captured the outline shape of the carvings and “branded” the surfaces of the components.

Tim

http://killenwood.com

Comments

Tim:

Truly an amazing piece. I used to use AutoCad (Rel.12) to design and create working drawings for custom homes that my construction company built. I have not yet tried Sketch-Up for designing and producing working drawings for furniture. My concern is that the time spent in learning the program and producing everything correctly would not justify using the program. Obviously you have a pretty good handle on the Sketch-Up program, and the vidoe was very well presented. I would be interested to hear your thoughts on the investment in Sketch-Up to enhance my work and time. And lastly, I was particularly drawn to the carvings. I do some of that myself, and am currently studying online with Chris Pye. I am finding it very valuable. Are you a trained woodcarver? But I must say,in closing, this piece just takes my breath away! Cheers, Sandy Maguire

Thank you Sandy, In my working life, I watched how traditional CAD tools changed and improved the design process for complex process plants, power plants, and other facilities. It was especially exciting to watch the transition to 3D and how this improved design and the communication to on site construction work of these complex process facilities.

At the same time, I was using 2D CAD systems in my furniture hobby but wanted the same 3D advantages in my own furniture making. I tried 3D in traditional CAD systems but could not get there.

SketchUp was a breakthrough for me. I finally could achieve full 3D capability in furniture design. It required about a month of full-time attention. That was about 6 years ago, and I'm very glad to have made that investment.

SketchUp and 3D has enabled me to tackle more complex woodworking tasks, including Windsor chairs. When you can model in 3D, the mystery is exposed, opening new possibilities.

On your second question, I am not a carver. I struggle with this and have not had formal training of any kind. I have watched the master cabinetmakers at Williamsburg, and this has been an important source of education. Also, I have several classic books that serve as good references.

Tim

Thanks so much for your response Tim:

I remember how difficult the learning curve was for AutoCad and I am just not ready for that lengthy process again. However, you have inspired me to look into Sketch-Up. When you discussed designing a rocking chair that really got me going. I have a stock of black walnut that I have been saving for years to build a rocking chair with. Although I used to build chairs for Country Coach, a major motorhome manufacturer, I have never tackled a rocking chair in my shop. Perhaps this is the time to learn the program. Hopefully my AutoCad experience will help. I'll let you know how it goes.

And many thanks for the inspiration to teach this old "bi.ch" that I can still learn new tricks. LOL

Take care, Sandy

Hi Tim,

Thank you for the great video, I always learn for your contributions. How do you do the "branding" of components? Thanks

To Rooms: The way I do "branding" is by using "Intersection" on the face of the components using a carving profile. I've had additional comments through email on this procedure.

So my next video and blog entry will show this process on one of the components of the Lowboy.

Tim

Log in or create an account to post a comment.

Sign up Log in