Look ma! No dovetails! Mosheim chose not to use dovetails when he mades the drawers for his desk. Check out the blog he wrote about the drawers. By the way, take note that the earth hasn't stopped spinning.

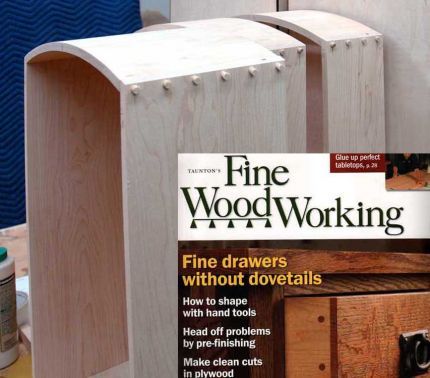

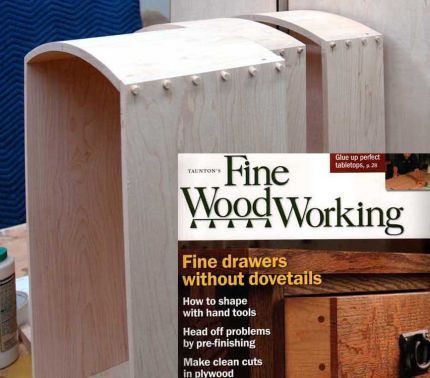

The cover of Fine Woodworking #208 shows a drawer constructed with pinned rabbets. The cover line and title for the accompanying article is “Fine Drawers Without Dovetails.” Evidently, the notion that a drawer without dovetails could be fine sends some woodworkers into a tizzy. I can understand their reaction. Dovetails are idolized by most woodworkers, especially hobbyists. Given that idolatry, it’s not surprising that some would take the suggestion that a fine drawer can be made without dovetails as heresy.

I like dovetails too. In fact, I use them to make all of my drawers. But I’m not slavishly devoted to them. And you shouldn’t be either. Just because some crusty woodworkers on internet forums look down their crusty noses at drawers made with joints other than the dovetail doesn’t mean they’re right. Don’t let them constrain your technique and design. In the end you need strong drawers that are attractive, and there are many ways to make them. Don’t let blind allegiance get in the way of beautiful furniture.

| More Dovetail Tips, Tricks, and Techniques • Router-Cut Sliding Dovetails • Make a Tapered Sliding Dovetail • How to Cut Sliding Dovetail Joints • Half-Blind Dovetails • Basics of a Half-Blind Dovetail Jig • How to Cut Dovetail Joinery |

A pinned rabbet joint, for example, is strong, attractive and looks much more handmade than, say, a dovetail machined with a router. Also, pinned rabbets are easy to make. You can use a dado cutter at your table saw, or a rabbetting bit in your router table.

Just in case I haven’t made my point clearly, here it is. Dovetails are nice, but aren’t the only nice drawer joint around. If you can handcut (or use a tablesaw) to make attractive dovetails, go for it. But if you can’t, use another joint, like a pinned rabbet. Check out this article by Matthew Teague for other options.

Of course, we’re all entitled to our opinions and here you’re even allowed to express it. So tell us what you think in the comments below. Is there room in fine furniture for drawer joints other than the dovetail?

Comments

Well said, couldn't agree more. I hate the clunky look of machine cut dovetails and, although I've used dovetails in some work, they usually need to be fixed after glue up due to my limited skill and tool inventory. I stress over having to cut them, wondering if I'll screw up and have to reproduce the part. Stress should not be a part of woodworking, at least for the amateurs among us. Let the pros stress the dovetails.

Thanks

Bill

Bill,

Thanks for the comment. I have to say that I didn't even think of how stressful it can be to cut dovetails. All the more reason to avoid them until you've mastered them. There are many options, just as beautiful and strong, that won't stress you out as much.

Matt

Of course, if you avoid them for too long, you'll never master them. ;-)

Hand-cutting dovetails on scraps has the same effect on your skills as hand-cutting dovetails on "real" pieces, except that the stress isn't there. Over time, you get better. Eventually, you gain enough confidence to use them on real pieces. Until then, you stick with other kinds of joints; hand-cut dovetails are just one in a range of joints that you'll want to master.

Whenever I'm milling up stock, I look for cutoffs that would be appropriate for use as "proxy drawer corners," and I set them aside for dovetail practice. Anything 2-4" wide and at least a couple of inches long will work; it helps to have a matching pair of pieces.

Don't misunderstand, I think that dovetails are an essential skill to aspire to and I've used them in the past. With limited time to practice and perfect them, I'll frequently use the time I have to substitute an equally lovely joint.

Thanks

saschafer,

You're right that you'll need to practice in order to get at hand cut dovetails. But why do you need to do them at all? I know of many successful furniture makers who are great designers and technicians that never use them. Modern woodworkers, especially hobbyists, seem to have made a fetish out of dovetails. And that's not good.

One of the problems I have with the overwhelming emphasis on dovetails is that it limits design. I'm not necessarily thinking of drawers here, but of carcass construction. When I gave up dovetails as the be all and end all for carcass construction, I realized that I could start to do cool overhands on the top and bottom and that I could make much more curvaceous cabinets. That was a good.

Matt

Why does one choose any joint over any other? It's always a juggling act: fitness of purpose, aesthetics, etc. If you're a beginner, then skill certainly factors into the equation as well. And aesthetics do play a big role; if aesthetics weren't an issue, we'd all be making screwed-together butt joints for everything.

But dovetails are an excellent choice for drawers (and other four-sided boxes); they're strong in the direction they need to be strong in. Machine-cut dovetails are just as strong and very easy to make, but some people find them to be lacking in aesthetics.

I guess I just don't see the fetishism that you speak of. There is certainly a lot of hype surrounding dovetails, but that's more out of (misplaced) fear than fetishism: Hand-cut dovetails do require a fair bit of practice. But so do hand-cut mortise-and-tenon joints, hand-cut half-laps, etc. People aren't afraid of those other joints, though, because they can make them by machine and no one will be able to tell the difference. You can't fake a hand-cut dovetail, but a well-fitting hand-cut mortise-and-tenon is probably harder to accomplish.

The reason I say that the fear is misplaced is because dovetails really aren't that hard. In the time between my previous comment and this one I cut a three-tail joint; I posted some photos here: http://www.dendroica.com/Scratch/dovetails.jpg.

I didn't time myself, but apart from the initial stock squaring, which was already done, I spent somewhere around 45 minutes or so, including fitting the joint together (it's not glued) and planing the surfaces flush.

The joint isn't perfect--you can see a couple of divots here and there--but it's not too bad. And it's not like I'm some kind of dovetail expert, either. The total number of dovetail joints that I've cut, including practice pieces like this one, is somewhere in the low double digits.

The wood I used in the joint, by the way, is an unknown species, salvaged from a packing crate from Tanzania. It's pretty soft and compressible, with workability something like a medium-density pine. It's a mixed blessing as far as cutting dovetails is concerned; the compressibility means that fitting the joints isn't too arduous, but the softness means that it's easy to screw up, and paring end grain is an exercise in frustration.

I feel that hand cut dovetails are probably the most overrated joint in the woodworkers arsenal. Unless you can cut them very quickly and very precisely they waste time, look sloppy and are much weaker than most other joints that could have been used. Factor in all the time it took to lay them out, carefully cut them, pare them to fit, fine tune them some more then fill the gaps after glue up....Doesn't sound like a lot of fun.

I make quality, one-of-a-kind pieces of furniture for a living. Having said that, I sometimes have clients that are drawn to dovetailed drawers, so I sometimes make them. It's almost never my first option. They do look great, but I feel there are other joints that are as strong, much easier to cut and look good too, so I use them. I would be burning $'s if I didn't use the other joints.

"Let the pros stress the dovetails", says a previous poster....I think many pros don't have the time to waste on dovetails when there are other options. The clock is ticking for us. I think it's the hobby woodworkers that have the time to spend on this joint, for the most part.

Rob Brown

http://www.equinoxinteriors.ca

I don't have much to add about Dovetails, They are good looking and insofar I cannot tell that a machine cut isn't done by hand, I can tell when one is hand cut most of the time but that is besides the point as I can be fooled as I believe many more woodworkers could be than would care to admit.

Since the difference between hand cut and machine cut joinery has been brought up I would like to know why there seems to be such a caste among woodworkers. Everyone has preference and opinion and I admire a nice joint for beauty and strength but I mostly look at the overall piece in terms of functionality, beauty and usability. I admire the woodworker that uses finely mated dovetails as much as I do the woodworker who only uses a reliable and faster rabbet joint, I hand cut mine as I like the work but no one would ever notice and that is fine by me. Instead of looking at why we are better than another for our mastery of one joint our time may be better spent mastering the joints that serve us the best.

is this all a babble? I can never tell. I aspire to be as good as any other woodworker here and maybe someday inspire another.

Dovetails are probably one of the most difficult joints to make well. Both woodworkers and laymen alike look at the dovetail joint as a sign of a skilled craftsman. Most laymen wouldn't know a machine made dovetail from a hand cut one. That being said, if you use any other joint, some people (both craftsmen and laymen) will see it as a sign of inferior quality. Why not just get really good at making them. Take a class. Rob Cossman has excellent DVD's as well as great classes on hand cut dovetails. He can make them by hand faster than with a machine and they look awesome. Just takes practice.

For me, I want to learn how to hand-cut dovetails precisely and aesthetically. As a hobbyist, it is a fascination to learn the skill. Certainly, as a pro, I would look at the cost-efficient way that the customer will accept - and pay for. I think that is true for any profession.

Back to the hobby/amateur issue. As I said, it would be fascinating - just as conquering that mountain peak or catching that trout or taking that one picture of a lifetime. It is the challenge and the attraction. But once done, why repeat it (if one could) if something else would do. And I must say, the pinned rabbets sure do look nice!

Thanks for the provocative article, Matt.

Matt,

I read this and couldn't believe how much trouble you went to trying to stir up contraversy here. You even imply hobbiests are drinking the cool-aid and practicing blind alegiance!

You say, "crusty woodworkers on internet forums look down their crusty noses." Are you a school kid trying to pick a fight?

It's like you're fabricating your own argument, then taking a side.

The dovetail is a fine drawer joint technique that one should aspire to include in his or her arsenal. Most people I know in the woodworking community would probably consider it the premier joinery technique for drawers. I don't believe that a significant percentage of those same people think it is the only acceptable technique.

Your piece attempts to characterize woodworkers who appreciate and respect dovetails as snobs who take a cult-like position about them. That's wrong. At the same time you characterize yourself as someone who can and does cut dovetails but is somewhere above this cult attitude you yourself fabricated.

What purpose is there in trying to have people take sides on this. Is FWW going the way of shameless tabloid editorials to stir the pot?

Frank Vucolo

What better way to enjoy your cherished hand tools than by handcutting dovetail joints? Whether the end result is better, worse or indifferent is (as seen above) strictly a matter of opinion. But if you enjoy the feel of a finely made and sharpened chisel easily moving through the wood, the speed and accuracy of a quality saw, the creative process of laying out an interesting pattern of dovetails...the end result quickly becomes secondary to the 'process' of getting there.

Yes I use dovetail joints and the reason is simple, it gives me pleasure.

I have a Dovetail jig with all the bells and whistles, it can make different size tails but you are screwing around with the setup, practice cuts adjust this knob the move that one and maybe you'll be close. That I think is more frustrating than making a bad cut with a Dovetail Saw, or missing completely and running the Dovetail saw across your finger requiring, time out to get stitches.

Hand cut Dovetails are the essense of Woodworking. They take time to master but with patience it comes. I finally broke down and took a two day class on nothing but Hand cut Dovetails and it was worth every penny. I just finished 7 shop cabinets all the carcases are dovetailed, you can go nuts with sizes and designs on width. I used Roof flashing(aluminum, cuts easy to make templates) The feeling of satisfaction of putting them together with your fist is a true feeling of knowing you have really accomplished something.

Thats how I see it.

A dovetail joint is one of many that should be mastered by any serious woodworker. It is a means to an end, thats all. As long as the construction technique aligns with the purpose and reason for making the project you can't lose.

Personally I like hand cut dovetails, mortise and tenon joinery and solid wood panel construction because it satisfies the purpose for my work.

Enjoy

If you make furniture for yourself do whatever makes you feel good.

If you make furniture for others do whatever makes them feel good (and if you charge them gives good value).

Dovetailing a joint together is a basic skill that traditional woodworkers needed to master in order to make a living. It was not considered any more difficult than any other operation. It's only recently that a mystique developed.

If mastering a skill makes you feel good this is a skill that can be easily mastered but needs practice.

If on the other hand you don't see the point of mastering the skill don't master it.

Personally I think however that if you do period furniture anything but period construction looks odd.

Joelm has it, thank you. This is put better than any other and is spoken as the very truth.

As a beginner for about 6 years, it seems to me that if you learn that dovetails are very difficult before you learn how to make dovetails then it will be very hard and intimidating. Ignorance sometimes is a blessing. (mea culpa). I never heard of dovetails before I learned how to make them so I was able to do it even as a beginner. The end result... well it's what you would expect from a beginner, but the end result does improve with time.

Are dovetailed drawers overrated?

I think some of the writers have done a pretty good job overselling the joint, and a market has being built around it. Mechanically, the drawers made with the joint have some advantages over other joints.

My 2 cents from a beginner perspective.

-Luis

Stress?... Now I've heard everything, woodworking is suppose to be fun, creative and relaxing. But Stressful, we are not navigating through Shark infested waters in a Birchbark canoe.

To each his own, Pinned joints are fine. Hell, you can use No.6 sinkers (box nails and call'em Swedish Dowels.) to pin the joints together. I read the article on drawers without dovetails and it is a quick and easy way to put them together, they even recommend trimming off a 1/16 on the bottom to create part of the reveal.

But trying to pass the pinned joint off being as good as dovetails, like comparing a Chevy to a Beamer, it just can't be done the aesthetics just aren't there.

Hi, there:

I am the author of the article in question ("Fine Drawers without Dovetails"). Like most woodworkers, I love the look of dovetails. They are strong, beautiful and traditional. I love to cut them, which I do completely by hand. I also teach quite a few people each year how to make handcut dovetails and I enjoy the process.

Having said that, some of my clients just don't seem to care. They want a joint that looks good and is strong, but they aren't stuck on dovetails as being the only option. So I always give them both options -- handcut dovetails and dowel pegged rabbets. They decide based on what they like as well as their budget. Obviously, handcut dovetails cost far more. And many people like the dowel look because they don't see it very often.

In my business, I only offer dovetails done by hand, not by machine. That, in itself, could probably stir up a whole controversy! It isn't that I think machine-cut dovetails are inferior or somehow "bad". It's just that in a machinery dominated workshop like mine, the dovetail is one of the few joints that I ever cut fully by hand so I see the process as somehow "special". While I do all kinds of high quality joinery such as mortise-and-tenon, including wedged, pinned and so on, I rarely get to do all of the work by hand. Hand tools always come into it at the most crucial points, using chisels and hand planes to achieve the proper fit. But I don't cut most joinery fully by hand, so I've sort of reserved that special process for dovetails.

The point of the article was to get people thinking out of the box a little and maybe accept that something other than dovetails can still be aesthetically pleasing and strong. I spend a lot of time each year teaching hobbyists how to build furniture, so I see them struggle with the handcut dovetail. And while I encourage people to practise and keep trying (it's the only way you are going to get better at it), for a hobbyist who can only commit maybe 3 or 4 hours per week to their hobby, saying "you just have to practise" sometimes just doesn't cut the mustard. Basically, I don't want struggling beginners to feel that if they can't make nice dovetails then they are somehow incompetent and should never even build a drawer. I give them a strong but much more attainable joint so that they can get on with their hobby with pride and a sense of accomplishment. Then, as their skills increase, they will naturally develop an interest in dovetails and wish to do it. Very few, though, will have the kind of time required to not only make the joint, but be able to "practise".

If there's one thing that will kill a beginner's interest more than anything, it's giving them a task that takes so long to get good at that they simply give up and decide to hit the golf course instead. Keeping that interest alive involves simpler methods that get the person from A to B with a sense of accomplishment. The finer techniques and skills always follow, but it can be too much to jump right in prematurely.

Anyhow, it is clear that some people found the article to offer a "refreshing" perspective, while others find the idea of not using dovetails for drawers almost sacrilegious! As long as it gets people thinking and questioning their goals and techniques, I think it's a good thing.

All the best,

Hendrik Varju

Passion for Wood

As a relative beginner, I struggle to make my pieces look as close to store bought perfection as I can. I very rarely suceed, but that's my goal. Is it the goal of very many woodworkers to make their pieces look less, so they are easily identified as handmade? I use a dovetail jig and router when I want that joint, but rabbets and dadoes work very well for drawers and things also. If I wanted to make it look handmade, it's pretty easy to slop a bit with the router and create a bit of an oops joint. In fact, I'm very good at that ... even when I don't want to be. What escapes me is why, if a customer wants dovetail drawer construction, would making them with a router and jig be so horrifying. Would that method not save tons of time, and therefore money, and allow people there desire without it costing "far more"? I do make things for family and friends as well as for my household, but not commercially. For the speciality woodworker hobbiest who enjoys spending hours and hours cutting and working with hand tools and/or antique tools, the old woodworking mystique holds true, and must certainly provide a tremendous sense of accomplishment. Otherwise, however, a well designed, attractive, functional, piece that will last at least for the lifetime of the intended user is, it seems to me, a reasonable and sensible goal for most woodworkers, professional or hobbiest.

I realize this is a slight departure from the main point of your post, but unless we are talking strictly about aesthetics, I see NO reason to pass up on the use of a dovetail jig. I'm a carpenter by trade, but consider myself to be at least a recreational woodworker. For me, beginning a jewelry box or some other casework with a nice clean set of jig-routed dovetails (I use the Keller system) gives me the confidence to try my hand at other more daunting upgrades on the project - wooden hinges, spinners, or maybe an inlay. Hand-cutting the dovetails right off the bat often leaves me feeling frustrated with my skill level, killing the momentum of the project.

Frankly, I think the lofty admiration of the almighty hand-cut dovetail is perpetuated by woodworking elitists, and it's added to drawers not for the strength it offers customers, but for the self-congratulatory pat on the back of the guy who spent umpteen hours hunched over the bench.

If purity and vanity are the the name of the game, then I suppose I should sell my jointer, thickness planer, and cordless drill, too?

See you at lunch, buddy :)

Your pal from Fine Homebuilding,

Justin

Are dovetails overrated? It depends...I recently walked through a new spec home in my area that had an extra 3K on the price tag because the drawers throughout the kitchen and bathrooms were dovetailed. Nice feature right? Well upon closer inspection the drawers were nothing special, just melamine veneer over MDF. I'm certain that in a few months/years those joints are going to fail simply because of the materials used.

The joint has its time and its place. Just because there are a million and one templates, gadgets and devices on the market to enable the quick production of machined dovetail doesn't mean they should be used on every product coming out of the shop. So many guys out there slap a dovetail into a piece thinking it's the key that is going to make their piece extraordinary, when in reality is distracts from the overall composition of the piece.

Melamine for kitchen drawers ? If anyone even considers buying that ought to pay an extra 3000 for that. I've never known anyone slapping a "set of Dove tails" on anything, hand cut dove tails take time, alot more that the machine.

So anyone who bothers to learn to cut dovetails is either Vane, a purist or an Elitist. And that from a Carpenter, ergo, it must be so and the self congratulatory pat on the back. Talk about an elitist attitude ? So you've done your apprentiship and you are done learning, that is a sad place to be.

Semper Fi, Buddy.

I'm not sure you understand. This is not a standoff about which joint where!

A woodworker cuts dovetails because he feels the joint requires them, or he wishes to have a joint that is pleasing to the eye. If he didn't think so, he'd do the joint differently. Why the superfluos argument?

The pinned rebated joint is fine as an alternative, but lesser joint to dovetails for drawers. I intend to try them one of these days. But there's no harm in aspiring to improve your skills to do hand-cut dovetails yourself one day. On the other hand, there's nothing that can replace the hand-cut dovetail for a blanket box, or similar piece. Although dovetails made with a Leigh or similar jig come close.

Hi,

I am a Carpenter by trade. I also build a fair amount of furniture. I was just asked to build a Captain bed for my

youngest Grandson. This will have 3 drawers in it, and they are 1/2 blind dovetails. I built the dovetail templet I use.

It was a Woodsmith design. It works great!

I have cut dovetails by hand... I like the Template better.

When I build other things, I try to use different joints.

I use mortise and tennon, or pocket screws, in some of the projects. Customers I build a house for, always want, Window seats, Shelves, Extra cupboards.

I get a lot of experience building different things.

Thanks,

Rod

no likem dovetails. prefer drumsticks. will settle with big rock as soon as can gettum back on stick(got to gettum new grapevine)brokum last grapevine in big marker discussion. other guy havum very hard head.

This has been an interesting blog to read but one of the things not mentioned is the importance of the strength of the joint and why dovetails were created in the first place.

There is no doubt that a dovetail joint is extraordinarily strong. This is, in fact, the primary reason they've been used in drawer construction for so many years. The reality however; is that technology has changed HOW a strong joint can be made and even, quite frankly, the NEED for a strong joint. Case in point- a hundred years ago there wasn't any such thing as drawer slides and certainly not the kinds we have today. When you built a dresser, your drawer front needed to handle the pull of the entire weight of the drawer and everything in it. That is no longer the case. Drawer slides allow for very minimal stress on the drawer front. This is NOT to say we shouldn't make all joints as strong as possible, it's just to give the history of why a dovetail joint USED TO BE critical. Combine that with the advances in glues and other simple to create joinery techniques and you have plenty of excuses not to spend time creating dovetail joints on drawers.

Having said all that, I do anyway. I create them with a router and jig and they come out looking fine, but I have to admit I question the extra time I spend on them every time. I never question it if aesthetics is an issue because I think a good dovetail joint is a beautiful thing to look at, but for pure strength... it's not my joint of choice simply for the time and effort required. I'd rather create a strong joint without another [quicker] technique and move on to my next piece of furniture.

I am uncomfortable with your sweeping assertion "Dovetail drawers are overrated" and consequently I think you are promoting a false argument. The many responses that fail to address your main question would appear to support my assertion.

The Dovetail is technically a superior method of joinery and to many, it has a pleasing aesthetic. Fine WoodWorking has carried many articles which respect both the technical craftsmanship and the creative use of the Dovetail. Such luminaries as Christian Becksvoort, Gary Rogowski and Carl Swensson spring to mind as being particularly lucid and pragmatic in their writings and opinions regarding the Dovetail.

I thought that Hendrik Varju's article in FWW208 was thoughtful and posed some well balanced opinions on the merits of Dovetails and Pinned Rabbets. Using the Pinned Rabbet in his project was wholly appropriate, it technically satisfied the stresses and strains of that piece of furniture and was an extremely attractive solution.

My own view is that the Dovetail is not overated but for the less skilled woodworker it can be intimidating, especially if it is to be cut by hand. In a personal project that required a "Fine Craft" outcome I would rise to the challenge and hand cut the joints. If I was making a series of built-in cabinets, whatever the application and the job required Dovetail joints then I would pragmatically resort to power tools and a jig.

I try hard to balance form and function in my woodworking projects. I am never afraid to try something new and that is why I subscribe to FWW, it provides a great inspiration and all those articles have become a wonderful resource to draw upon. Keep up the good work!

Couldn't agree more. Dovetails are nice when you have the time and the budget. Otherwise they are not a commercially viable option. Most clients will not pay the extra $$$ for them. I have never had a pinned rabbet joint drawer fail in over 20 years of woodworking.

Dovetails were created to make a strong joint that would stay together under heavy use. There were no power tools at that time so everything was had crafted.

Since even dovetails can be machined these days the only debate should be the strength of the joint vs a pinned rabbet.

So I'll be waiting to see your test results!

Dovetails are so cool. I've been using them for years. If all of the joints are stronger than they will have to be for the survival of the piece, why not use the one you want. It's dovetails for me.

Hand-cut dovetails are like practicing the scales on a piano before playing. If I have been out of the shop for a while and am about to start a piece, I will cut dovetails from scrap just to get the juices flowing and my hands into the game.

Hand-cut dovetails are like practicing the scales on a piano before playing. If I have been out of the shop for a while and am about to start a piece, I will cut dovetails from scrap just to get the juices flowing and my hands into the game.

This discussion reminds me of the sharpening fetishes that seem to abound.

If you like dovetails, make 'em, any way you want.

If you like pinned rabbets, make 'em, any way you want.

Sort of like asking what time it is, and people getting off on telling you how to make a clock.

Wow I never thought so many wood workers would completely miss the point.

Hand cutting dove tails has it's place (Traditional reproduction furniture and cabinetry for one)

But half blind dovetails cut on a jig with a router (or in a industrial Dovetail cutter) make a great joint and is one of the quickest ways to build a lot of strong drawers quickly. I have built a kitchen full of drawers (over 30 drawer boxes 3 different depths and 6 different widths.) in half a day. (oh and these are dovetailed back and front and the bottom is fully captured not slid in and stapled at the back.) And the backs are notched and drilled for Blum under mount drawer glides.

How? I make parts in a production style I have a very detailed cut list and repeatable jigs and setups that I do not need to measure I simply put the parts in the jigs and cut the assembly takes the longest time but again I have clamping jigs for the most made sizes I make.

I am sure if I had Jigs and machinery to cut a rabbeted box joints I could do it that was as quickly also. But why? a Dovetail looks good, customers do not need to be convinced of it's quality as a strong joint and it is fast and easy to do with the proper tools and setup.

Why is the dove tail the holy grail I do not know But I do know that historically it was used because it does not rely on glue to stay together.

Also many traditional joinery takes wood movement into account if you build a chest out of solid wood (not plywood) you simply can not glue a long cross grain joint you need a mechanical joint that will not pull apart but will also allow for movement. so a sliding dovetailed dado vs straight cut dado for case

construction.

Sure there are other joints but I just do not except that any of the other are better then the dovetail joint it is easy to assemble and it is easy to make and it does not rely on glue alone to resist pulling apart. And requires no pinning no nails no screws.

As for learning to cut dovetails by hand well it is taught because to make a tight dove tail (and end up with a square box the correct final size) requires many wood working skills from planning and measuring to cutting. So it is part of being a complete wood worker.

As Carpenter the first thing I ask a new apprentice to do is build a set of horses and I can tell by how well they do this just what kind of carpenter I am dealing with. Sure you can go buy a set of horses that folds up and is easier to move from site to site but that does not tell me just how well a apprentice is going to measure cut and assemble framing or finish trim on the job but If they make a perfectly matched set of horses that do not wobble and tight joints then I know I have a worker I can count on.

And that is the same for the dovetail it is a joint you can see after it is assembled and it is a indicator that the rest of the furniture is also assembled with the same care and attention to detail as that joint was cut.

You can not see if a tenon fit snugly after it is assembled (unless it is a through tenon) but it is a safe bet if there is also hand cut dove tail that is tight and well proportioned and the angles are consistent and the sizes of the pins and tails are uniform it is a safe bet the rest of the attention to detail was just as meticulous.

Yes

I'm far from being "done learning", MotorT. I continue to challenge what I know and how I do it. I can and have cut dovetails by hand, too. I just prefer to use a jig because it's quick, clean, and most of the time I'm not too concerned with not being able to create super-thin dovetail pins.

I'm simply saying that if the argument is about anything other than aesthetics--the true craftsmanship of woodworking for instance--then why not cut tenons, box/finger joints, rabbets, and dados by hand as well? Why not throw away the router and invest in molding planes? Why not sell the jointer and buy a set of jointing planes?

I just think it seems hypocritical to draw a line in the sand about dovetails, but then defend power tools and other jigs as perfectly acceptable "efficient" options.

Hand-cut dovetails can be fun to learn to make. I spent a couple of Saturdays and several evenings in the shop with my dovetail saw, and a pile of scraps. No pressure, no deadlines, no design specs ... I just kept sawing away until I felt comfortable moving on to a real project.

Deciding on the joinery method is sort of like choosing the right tool for a given job. Dovetails are strong and can be attractive, but other joints can work just as well depending on the material you are using and the application.

I have made a few projects with box/finger joints, but the drawers in my shop cabinets were all done with lock rabbets.

Why did I use lock rabbets? The drawers were all built with 3/4" stock, the lock rabbets are strong (though not as string as dovetails), and I can do them in a fraction of the time it would take to do dovetails. If I were using 1/2" stock for the same drawer, I would probably have done them with dovetails for added strength.

I have been working as an artisan for almost 8 years now. Artisan being a person who make a product with dexterity. I am also a woodworker, but I work in glass, metal, and do my own design work from scale dimension drawings, mock models, and proof of point research. Being adept in many trades has gives me almost an outsider view of the woodworking world, and an interesting view of all of you die hard wood guys and hobbyist players alike.

I learned dove tails only a year ago. Never had the need for them.. still have not, but I want to and know I will. I make drawers depending on the project, but I know dovetails and I can cut them by hand or my machine (router, table saw, band saw, etc). This argument though intriguing... is silly. I want to gain as many skills as my talent can pull in and use.. one skill always leads to mastery of other things as well.. some that can surprise you.

Aesthetics are learned appreciations not instinctual design. To the general masses a dovetail means as much as can of soup.. they may have heard it or even know what it is but they know noting intrinsic about the joint or the process. They also do not care other than what we as artisans tell them is important to know.. interior designers do the same.. but they also DO NOT understand the process only how to sell the joinery.

I was told back in design school to "Learn by hand and you will know what the machine does." You have more control over the joint, the process and the project... if you know why and how the joint works. When I teach.. I encourage my students to know their body. Their body is the most important tool in the shop. Dovetails... above all things are about how your body relates to the wood. How you stand and hold the saw... how you chisel and chop and pair down. It is not elitist, purist, or bad in any manner to love and master ones body as a tool.. and dovetails really are the most visible expression of skill there is in woodworking. But the neither joint nor the process should control you. Personally I do not believe in teaching to the tool.. nor to the market.

But then all of us came to woodworking in different ways and have different desires for what we get out of the trade. Follow that path.. your own.. and to emphatically argue one way or the other.. is more damaging than elitism.

I would like to dispute this one specifically

dlrosenbloom writes: Couldn't agree more. Dovetails are nice when you have the time and the budget. Otherwise they are not a commercially viable option. Most clients will not pay the extra $$$ for them. I have never had a pinned rabbet joint drawer fail in over 20 years of woodworking.

In fact half blind dove tailed draw boxes is one of the most commercially used draw box joints. Yes They are Machine cut half blind dove tails but they are used in most commercial kitchens and better commercial furniture.

If you want to compete with IKEA and Walmart for the low ball price then go ahead and and don't use-em But frankly I say good luck no matter what they will still be cheaper.

If you want to Compete for the better paying clients that have money even when times are bad then you give them quality they can see and that means dovetail joints. Even KraftMaid uses dovetail draw boxes.

I know with modern glues a rabbeted joint is very strong but It is about perception and it really does not take any longer to do if you have the jigs and machinery to build-em.

And no customers do not pay more for dovetails alone but they ARE willing to pay more for Perceived Quality that is why Abercrombie can sell the same made in China jeans that sell at WallMart for $19.00 for $70.00.

If strength was the only criteria I could just rabbet and glue and then staple that bottom on and then let the draw glide hold the bottom and it would be plenty strong enough after all My work bench drawers get more abuse then any desk draw and I put much heavier tools in them and they hold up fine but they don't look so nice.

I agree, dovetails are made too much of. They can be distracting and frankly, way over used. With that said hand cutting decent dovetails is still a threshold skill just like learning to sharpen plane irons and chisels, or making a good mortise and tenon joint. They're necessary steps to learning how to make stuff. Or a reason to hide out in the shop.

I have to say first of all that woodwork is a bit of

an art and a good deal of skill and imaganation too.

I think Dovetails are great to be able to do and i try to achieve this type of finish as a way of showing off the skill level. This is probably whats mixing up the argument here. Probably a bit of the snob level when infact people should not be hung up on the fact that its the 'b' all and end all of woodwork because its not. Everyone to there own. Once a finish of a piece is well finished then thats all that matters, in my view. In fact i wouldent be graet at doing dovetails by hand , i use the woodrat which is a great little tool i have to say. I've mastered this to a 'T' and its great. The dovetails from this machine look like they have been done by hand. Anyway, thats my little bit!!!

As a hobbyist I have been building furniture for about 15 years, using a jig to cut dovetails. The time to set up this jigs compared to the time it takes to hand cut pushed me to take a class to learn how do it by hand tools. The class was taught by Mario Rodriguez and Alan Turner. Once you learn the technical side of it, the rest is practice. So my pieces are not perfect, but the time sitting down with the saw in my hand, with sharp chisels and a knife ready at hand,without the roar of a machine, provides such a moment of tranquility that I enjoy very much. That is the main reason I cut dovetails by hand.

In all of woodworking, there is no topic more worn out than the virtues of dovetails. We've heard it all before, a thousand times. Doug Irish said it best.

About Mosheim's Desk drawers they have one feature that makes a problem for most standard dovetail jigs curved fronts don't want to lay flat in the clamps of a dove tail jig so in the that specific case a router cut half blind dovetail would require a specially made jig.

Also for Mosheim's drawers great for one set of drawers but build 20 sets or even 100. and you will find drilling and pinning all those drawers vs setting up a jig to cut dove tails takes longer to do and to assemble.

But again it would be a specially made jig for curved drawer fronts but once made you could make curved drawers faster and just as strong. (the pinned drawers Mosheim made are very strong maybe even stronger then dovetails)

So I am not saying dovetails are the only way to make quality drawers I just want to debunk the myth that dovetail joints take longer and are less cost effective.

I feel they are the easiest way to build a quality drawer once you have the tools.

Don't you just "love" the way defense mechanisms have been triggered? As one who has learned how to hand cut dovetails, I still don't practice that technique enough. I agree with many that this style of joint isn't the only one out there.

However, I look at the experience in learning to cut a dovetail joint by hand as a link to our woodworking past - those masters who are our history. I now have a greater appreciation for period furniture, even if that isn't my favorite style.

As woodworkers, regardless of skill level, we should be constantly learning. Any of us who aren't willing to take up a challenge to learn and perfect a differnt skill will be left by the wayside. I know of several skilled craftsmen who have a project pipeline of at least one to two years out who use not only handcut dovetails, but also have skills in other styles of joinery.

In my humble opinion, handcut dovetails are only considered "elitest" by those unwilling to appreciate and learn the skill required to make the joint. Believe it or not, some dovetail jigs take longer to set up and use than it takes to hand cut the joint for someone that has mastered the technique.

Bullfeathers!

Dovetails, tenon joints and other nifty woodworking tweaks may be just the thing if you're an artsy/craftsy woodbutcher. But, after more than 50 years of eking out what passes for a living as a carpenter who gets paid by the job, I wouldn't trade my drills and dowel stock for anything else. Never had a joint or drawer fail yet and I have a whole whack of them in daily service.

every method of joinery has it place, and it's up to craftsman producing the item to decide which one is right. beauty and art are in the eye of the beholder.

I use both pinned rabbet joints and dovetails, but when I use dovetails I go to great length to make it is evident that they were not done with a router.

One assumption that many make is that dovetails are "best" both due to their difficulty and mechanical strength. In most cases the application seems to be for drawers, so how strong does the joint really need to be? A more important question to ask is what type of joint should be used that meets the design criteria of the piece that still provides sufficient strength? An Arts & Crafts piece might benefit more from a finger joint. Mid-Century Modern from a pinned rabbet. There are plenty of design styles out there that would be better executed (from a sense of design) without automatically defaulting to dovetailing.

Reading through the postings the general consensus seems to be that hand cut dovetails are the pinnacle of woodworking skill and as such we all must strive toward mastering them. Dovetails have become synonymous with “the right way” when perhaps it should be synonymous with “because we have always done it that way”.

We praise innovation in furniture design, but I would be willing to bet that the first thing any of us would do is pull out a drawer to check for dovetails using that to base our opinion of the construction on that.

Why did this one aspect of woodworking become the measure of one's skill? Were dovetails not created originally because they afford both tremendous strength, and beauty? Today we have many more options for providing the required strength (How Strong Is Your Glue?) but the stigma of a drawer without them remains. This is evident when talking to anyone with virtually no knowledge of woodworking, they always want dovetails even though they don’t know why.

If creativity in furniture design is so admired why not in joinery as well?

I only have my opinion on what everyone here has to say, since I'm only a beginning novice here. For me, I'm looking to learn every different way of working with wood I can possibly learn, and learn it from every source I can possibly come across. I will develop every skill I possibly can. For me nothing is stressful, because of the enjoyment and satisfaction I get from working with wood. Some things are definitely challenging as I start to learn, but that is part of what makes this so enjoyable for me. The culmination of learning to use the various tools, whether it be power or hand tools, and to make something as pure and beautiful as one can only make working with wood is immensely rewarding. To both myself and those I share my work with.

From what information I can gather, I don't think anyone from my beginning novice starting point to the well experience can say there is "only one right way" to make things. I do believe that certain joinery methods are superior to others, but that doesn't necessitate their need in every situation. No one can argue the integrity and aesthetic beauty of a dovetail joint, especially the aesthetics and feeling of accomplishment with a skilled hand cut dovetail joint.

The real question is not whether or not dovetail joints (whether you use power tools and jigs, or hand cut them) are overrated. They are definitely NOT overrated! They have earned their place of stature for a reason. However, with advances with glues and hardware, we do now have other options that will meet the needs and intents of the person constructing them.

So, why is everyone arguing? We each have different experiences, and different backgrounds to draw from. As well, each of these different methods have their own merits for their intended purposes. Work the way that makes woodworking enjoyable for you, while accomplishing your intended purposes.

For me, I will continue trying to expand the boundaries of my knowledge, experience and skills. I will also keep trying to gather an increased knowledge and understanding to improve and expand my skills as much as I possibly can from each and every one of you that you're willing to share with me your individual insights. Regardless of whether or not we agree, your knowledge and insights are and inspiration, and are invaluable to me! Even when we don't agree, it often helps me to think of things I never would have thought about without your insights.

I'm not sure I agree that dovetails are over-rated, but I do think that there are a lot of folks who may assume that if a piece has dovetails, it is automatically a piece of "fine" woodworking. I think the distinction is that really good dovetails or any other truly well crafted drawer joints can be considered fine woodworking and then; there's everything else in varying degrees of "well-done-ness" whether dovetails or otherwise.

Pinned rabbets are great... if you want the drawer to look like children's furniture and fall apart in a few years. I'm not saying dovetails are the only way, but they beat the pants off pinned rabbets. Just my opinion.

overrated,,,heck no.

I do a lot of period furniture and use them all the time and love them, especially hand made.

But I respect and understand the use of other means of building drawers and those techniques have there place.

To my liking they're the strongest joint for drawers but I know I could be proven wrong,,,it's just a matter of personnal taste I guess.

OSC

When fish glue was the best adhesive available, dovetails were the best assurance of long life, and antique hunters are aware of this. We don't yet know how long modern adhesives will last, but if we don't expect our product to last more than a few generations, any strong glue joint will suffice. The box joint may even be better than the dovetail, because of its great gluing surface. If we're building something we hope will be museum quality in 2109, it would be prudent to resort to dovetails.

Survivability aside, dovetails have two major assets:

When fish glue was the best adhesive available, dovetails were the best assurance of long life, and antique hunters are aware of this. We don't yet know how long modern adhesives will last, but if we don't expect our product to last more than a few generations, any strong glue joint will suffice. The box joint may even be better than the dovetail, because of its great gluing surface. If we're building something we hope will be museum quality in 2109, it would be prudent to resort to dovetails.

Survivability aside, dovetails have two major assets:

When fish glue was the best adhesive available, dovetails were the best assurance of long life, and antique hunters are aware of this. We don't yet know how long modern adhesives will last, but if we don't expect our product to last more than a few generations, any strong glue joint will suffice. The box joint may even be better than the dovetail, because of its great gluing surface. If we're building something we hope will be museum quality in 2109, it would be prudent to resort to dovetails.

Survivability aside, dovetails have two major assets:

When fish glue was the best adhesive available, dovetails were the best assurance of long life, and antique hunters are aware of this. We don't yet know how long modern adhesives will last, but if we don't expect our product to last more than a few generations, any strong glue joint will suffice. The box joint may even be better than the dovetail, because of its great gluing surface. If we're building something we hope will be museum quality in 2109, it would be prudent to resort to dovetails.

Survivability aside, dovetails have two major assets:

When fish glue was the best adhesive available, dovetails were the best assurance of long life, and antique hunters are aware of this. We don't yet know how long modern adhesives will last, but if we don't expect our product to last more than a few generations, any strong glue joint will suffice. The box joint may even be better than the dovetail, because of its great gluing surface. If we're building something we hope will be museum quality in 2109, it would be prudent to resort to dovetails.

Survivability aside, dovetails have two major assets:

When fish glue was the best adhesive available, dovetails were the best assurance of long life, and antique hunters are aware of this. We don't yet know how long modern adhesives will last, but if we don't expect our product to last more than a few generations, any strong glue joint will suffice. The box joint may even be better than the dovetail, because of its great gluing surface. If we're building something we hope will be museum quality in 2109, it would be prudent to resort to dovetails.

Survivability aside, dovetails have two major assets:

Choice, Freedom, Creativity, Thought Provoking, and Fun...these are just a few of the reasons that I am a woodworker. I love it because I am free to be creative and create joints the way I want to create them and use what ever I like as long as the function is not compromised.

The ancient Egyptians used the dovetail joint because it works. I use dovetails because I want to. I use other joints because I want to. I am glad to have so many options available to me when I need to create a strong and attractive joint.

To say someone who does or doesn't use a particular joint when building a piece of furniture is wrong is like saying that someone who likes green beans is wrong.

Fine Woodworking uses the dovetail in their logo. Why? It represents beauty and strength, not to mention its one of the most well known joints ever created.

Use what you want, when you want, where you want. Don't let anyone try to fire you up by saying one joint is snooty or wrong.

Choice, Freedom, Creativity, Thought Provoking, and Fun...now this is woodworking.

I use pocket holes for drawers, and then put a drawer face on the front. Easy alignment, fast, strong and invisible.

Snobby or not, when someone tells me to look at their great piece of custom built furniture - I immediately pull out the drawer and check if it is dovetailed or not.

Other joints are just as strong and have their place, but nothing screams out "custom" and "well built" as much as a dovetail on a drawer box.

For the other 99% of people that wouldn't know or couldn't tell the difference, other joints are just as good, if not better. I guess we have to play to the audience and go from there.

I'm kind of agreeing here with wboettch and a few others. Stress should not be a part of woodworking. As a 55 year old who has just in the last few years gotten really interested in woodworking, and as someone who has a full time job AND other hobbies too..I simply don't have the time to stress over dovetails. I have tried a few by hand on scraps and they aren't easy to do. Nothing I've made so far has REQUIRED them so I guess I'll continue to practice when time allows but that probably won't be often. When you have limited time and just want to enjoy a few hours here and there producing something out of wood I don't see the point in stressing over it. I don't think I have a single friend who cares that my being able to do dovetails is what would make me a super woodworker vs just a decent one. They already think my stuff is pretty cool.

Honestly, I aspire to making good dovetails because they are not the easiest joint to make and i want the personal pride of being able to increase my skill level. To my mind, applied fronts scream of cheap, fast, and easy whereas dovetails show pride, quality, and skill. Even more so if they are hand cut. Machine cut dovetails are obvious and don't aspire to the skill level of hand cut. Whereas they may be "stressful" handcut dovetails give a certain pride in my work that is greater than I get with easier joints.

IMO - a vertical sliding dovetail for the front drawer joints is the strongest at resisting pulling force... but it's pretty much hidden and therefore not "sexy" at all.

Machine-cut dovetails are a dime a dozen, but they do make a good strong drawer. They're fast for applications like kitchen/bath cabinets and other utility pieces.

I think the the holy grail in free-standing furniture making are hand-cut, hand-spaced dovetails with creative twists in the angle of the pins/tails, creative decorative spacing, etc. This is true joinery that puts the practitioner's skill and creativity on display at the highest level. But they're not right for every style or every piece. The pinned dado also looks good, can be done very creatively, and is well-suited for 'moderne' and art deco type pieces.

Understanding the right mix of aethetics and form/funcion is what separates the masters from the hobbyists. It takes a mix of creativity and "thinking outside the box" with good historical roots and knowledge of classic forms. There's no shortcuts.

-Moo

Hemdrik, that was a great article. I am hobbyist woodworker and have been doing that for over 40 years. However, I just did my first hand cut dovetails about a year ago and truly enjoy doing them, although, I admit, they are not easy and you must stay in practice. I also have the Porter Cable 24" Omni-Jig and an older jig for half blinds, but have yet to use either one. When I started using hand tools more recently, having been a power tool junkie for most of those years, I wanted to learn as much as possible about how to best use them and refurbish old ones. I have found I have learned a tremendous amount under the tutelage of a master craftsman for a couple of years. Now, I use both power tools and hand tools- using the one that fits the situation the best and gives me the results I want. In short, I believe there is a place for both jig-cut and hand cut dovetails, and for any other type of joinery that the craftsman and the client wants.

The pegged joints look very classy and provide a different look- something a little unusual, and definitely strong enough for modern drawers.

Keep up the great articles.

Thanks,

Barry

To me dovetails fall into a category of things that could be done a number of ways, but, among those things, a certain one carries the panache of being of "fine." A short list would be silk instead of a synthetic, cork wine corks instead of plastic, crystal instead of glass, etc. The point isn’t functionality but rather the subtle communication of a trait which is perceived as a cut above the ordinary. BTW I cut dovetails with a router jig which is yet another distinction between the ordinary and the extraordinary. In fact, among wood workers, the power versus hand tool divide is perhaps the ultimate example of functionality versus aesthetics.

All of this brings us back to the question of which is best and the only reply is the maddening: “it depends on whom you ask.”

Finger joints are stronger (given modern adhesives).

The Hall brothers (builders and furniture makers for the Greene brothers) didn't use them. It would be a strange arguement that what they built wasn't fine furniture.

There is no reason for using dovetails other than someone's personal preference.

I went some time ago to Winterthur to look at one of the Rhode Island Quaker's block front kneehole desk. I had seen those beautiful, slim dovetails in photos, but never in person. I was shocked to discover that they took no trouble whatsoever making the dovetail on the outside of the drawer front look particularly good -- saw cuts on the tails went well beyond the base of the pins. But they were still exceptionally strong. The object was strength, not beauty. It is us contemporary woodworkers who want our dovetails to look as good as they can. And that's why I do it -- pure pride of authorship. I've even gone so far as to space (on some deep drawers) the pins on a Hambidge progression from the center up and down (to enhance the beauty of the dovetails by adding some cool proportioning.) But the primary reason is still strength -- satisfying my own ego with slim, pretty dovetails is still secondary.

Hello All...I am very new to woodworking. I am almost finished building my first workbench. It has lots of mistakes and several extra holes in the 4 x 4 legs. I love it. It is strong and despite the flaws...I made it!

So I just read all the comments on dovetails.

I took away one thing from the discussion.

Mastering the hand cut dovetail takes lots of practice and some special tools.

This got me fired up! I love new things. I can't wait to go to the Woodsmith store and figure out what I need. I may even try to find the Rob Cosman video.

I don't really have an opinion about the aritcle. I just wanted to say I appreciate everyone's comments, as each of you offered great perspective. It is the passion everyone has for this subject really makes me want to get in on the fun too.

Oh and to Rob Brown. I went you your website...Your stuff is beautiful.

I have to wonder how many actually go around to people's homes and pull the drawers out to see if they meet their specific ideas of perfection. I'm a shop teacher and I do teach dovetails but dovetails are a constructiton technique and I look for overall design excellence in a piece., I have seem some really ugly pieces with fine dovetails because that seems to be where the emphasis is among most hobbyists' peers. I've often wondered how the different joints stack up under stress. I think it would be an excellent article fot Fine Woodworking to do a joint shootout to see which type of joint results in the strongest assembly.

It depends on the furniture being built. Sometimes i use the dove tail joint, but i "jazz" up the joint by making cut half of the full dove tail, then reset and make another cut making the dovetail to look like a stepped dovetail. my choice of joints is the box joint for appearance and strength. The use of any joint is in the eyes of the builder, he is the artist.

Hand sawn dovetails, if done properly, are certainly one hallmark of "fine" furniture. It shows a level of skill and craftsmanship, time and dedication. It's a solid joint, and will last a long time. But, they are certainly not the only joint to use if you want to craft "fine furniture". Any strong, attractive joint, if done well and executed with care, provided it matches the style and/or period of the overall piece is acceptable.

It comes down to strength and aesthetics. Sometimes, the dovetail is the best joint for the job, and sometimes it's not. But, no matter the joint used, if the finished piece looks great, and is sturdy, then it's fine furniture.

With modern glues,it's a toss up. Drawers such as the one featured in the last issue are just as strong, even without dovetails. Machined dovetails, dependent on the jig manufacturer, can be junk and they don't look right anyway (unless you are reproducing a 19th or 20th century factory piece), so you might as well use dowels (pegs) or even wrought finish nails for that matter, it more traditional. That being said, it's all in the type of furniture you build. Most of mine is period and requires the use of handcut dovetails, so I'm going to wind up cutting them anyway. It was after all the finest of 18th technology.

There's nothing quite like a dovetail joint, unless it's a Japanese joint. But that "nothing quite like" feeling mostly resides with the woodworker; dovetails are beautiful, but more than that they're personal. A drawer with a solid wood face that's put together with pocket joints is a drawer every bit as strong and beautiful. The pocket joints are hidden. My first table was built by hand. The mortises were chiseled, the tenons were hand-sawn, the dovetails on the drawers were drawn out and hand-cut. We love that table--but the entertainment center I'm building from maple won't have dovetailed drawers. It will have solid wood drawer boxes with solid wood faces--and pocket screws holding everything together (pocket screws that will never be seen). I'm certain I will love it just as much as that hand-chiseled table.

I've read most of the comments. I've been woodworking for a great many years, but have only fairly recently gotten to the point of calling myself a "fine woodworker." I just recently built a grandfather clock that took me 17 months. On the base, I joined the sides to the front with hand-cut dovetails. I did it because I thought it wood be a nice touch aesthically. They turned out great - actually much better than I anticipated and it was the first time I ever made dovetails. I also have to admit I have no idea how to make machine cut dovetails, so my only options were hand cut them or use some other joint.

For those who are in my situation, i.e., amateurs, and never made hand-cut dovetails before - go for it. I'm sure other joints would have accomplished the same strength (albeit without the same look), but the sheer satisfaction I got - feeling like I've made it to the Big League in woodworking - was worth it personally to me. I don't care about the strength; any joint at that point would have sufficed, but I always knew the hallmark of a fine woodworker is his joinery, so the satisfaction to me when I step back and the admiring comments I receive (admittedly from people who wouldn't know a Phillips head screwdriver from a hack saw) are worth the time and effort for making hand-cut dovetails.

Ultimately, except for professionals, doing all this is for the enjoyment. Do what enhances your hours of enjoyment in your shop, but always strive to learn and do something one step better.

Both joints are strong enough for the application. Woodworking is not only about the integrity, longevity, and quality of the piece, but also the beauty, tradition, craftsmanship, and effort that goes into the piece. Production versus perfection. For a multi-set bedroom suite for my child the pinned rabbets may be fine. For a special 'one of a kind' piece dovetails meet all the criteria for elegance, tradition, and timeless. I always look at the sides of drawers before judging a piece.

I haven't read all of the comments so perhaps someone else has brought up this point. I have seen many drawers with dovetails and in some cases the dovetails(machine cut) are executed well but the rest of the drawer is junk, particleboard held together with staples and installed with cheap slides. I'm referring to certain lines of factory made cabinets. The point is, just because a drawer has dovetail joinery does not make it a piece of fine woodworking, and conversely, a well made drawer with first class materials can be an example of fine woodworking without dovetails.

Dove tails? I love 'em! When well done, I simply have to touch them.

Drawer slides are great for the modernistic look, they can be incredibly strong, carry a lot of weight. I try to shy away from that work...

I feel satisfied when I see a well done dovetail....says it all for me.

Seems I recall Fine Woodworking doing comparison tests of the different joints in wood....dovetails ranked up there at the no. 1 or 2 spot, as I recall.

Do what turns your fancy, or the clinet's, just do it well...

I have to laugh a bit at the whole issue. Is it a reproduction of a 17th or 18th century piece where dovetails are needed to be a true reproduction? Do you have to make 15 drawers for your kitchen where machine cut dovetails are good enough? Are you using up scraps of various hardwoods in your stash to knock out a quick & dirty toolchest where a pinned rabbet is more than good enough? Function first, then form but above all else have fun, it's a hobby!. Time = Money is just as valid at the hobby level as it is at the business level.

Having subscribed to FWW from its beginning, it is my view that cutting dove-tails has been covered to the point of fatique. Maybe there are not enough other topics to write about.

I am very fond of dove-tails, and have used them for strength and for decorative value. I think the old timers didn't consider them decorative. With that in mind I have in making jewelry chests or my grandaughters used blind mitered dove-tails. This is a very good exercise. Having just finished one of those I was able to point out this joint in an antique chest to the dealer who was unaware of it. I think he jacked up his price!

I agree Justin. Where would furniture production be without machines. No question. I made my first drawer at age 15, my step-father was a Trim carpenter, from Denmark, for the next three years I spent summers installing kitchens, cabinets countertops the whole 9-yards. The drawers were over lap drawers held together with 3 no.6 coated box nails per joint, and when he was done it was a beautiful job. He called them Swedish dowels.

If it works fine do it if it suits your purpose. But I have never seen so much complaining, and, yes, attacking one type of joinery. As I said below I just learned how to make Dovetails with a chisel and saw. I had the same ideas everybody else did, don't need them , too tough and on and on take way too much time. Unless you are under time constraints, have a schedule to meet, is not the purpose of woodworking: supposed to be, fun, relaxing, change of scenery from the "ball and chain", a shop in the woods. But I see people going to great lengths to convince us or themselves that dovetails are not worth the effort, fine, you know whatever 'floats yer boat' but as a joint if it had no merit it would NOT have lasted for a couple thousand years.

Did you know Dovetails date back to before Written history. They have found them in the Pyramids. I have even read that dovetails are antedeluvian, before the flood. So my friends they are not going away, any time soon.

It is what you might call where we came from as woodworkers. Its part of our history.

Personally the fuss about dovetailing makes me laugh that there are people so obsessed with this sort of thing.

The reason that they are used is for strength and in some cases aesthetic. But if the question why you use them was asked of a furniture maker 100+ years ago I think they would have had an interesting perspective.

Probably around the point that this form of jointing is the normal way to put things together so what is the fuss about (Probably not their terminology)

Having been a furniture maker for 30+ years all I do is cut them by hand, most times in the traditional manner by not measuring but by eye. This is how I have always done it and always will, as to the mystique there is none it is just part of the job.

Personally the fuss about dovetailing makes me laugh that there are people so obsessed with this sort of thing.

The reason that they are used is for strength and in some cases aesthetic. But if the question why you use them was asked of a furniture maker 100+ years ago I think they would have had an interesting perspective.

Probably around the point that this form of jointing is the normal way to put things together so what is the fuss about (Probably not their terminology)

Having been a furniture maker for 30+ years all I do is cut them by hand, most times in the traditional manner by not measuring but by eye. This is how I have always done it and always will, as to the mystique there is none it is just part of the job.

Personally the fuss about dovetailing makes me laugh that there are people so obsessed with this sort of thing.

But if the question why you use them was asked of a furniture maker 100+ years ago I think they would have had an interesting perspective.

Probably around the point that this form of jointing is the normal way to put things together so what is the fuss (Probably not their terminology)

Having been a furniture maker for 30+ years all I do is cut them by hand, most times in the traditional manner by not measuring but by eye. This is how I have always done it and always will, as to the mystique there is none it is just part of the job.

For craftsmanship, elegance and interest, I'd pit the pinned raised finger joints of the Greene brothers against any dovetail joint.

Tugg

Funny how judgemental we can be as crafters...

Considering the strength of the dovetail joint, there is little doubt of its appeal.

As mentioned in the editorial, Mr. Kenny brought up the machined dovetail...

As a true purist, only a hand cut dovetail should be put at the top of the heap in my opinion.

When the Egyptians were employing the dovetail... They didn't have the advantage of the host of engineered adhesives... They needed a mechanical advantage, which the dovetail provides.

What is the use of the drawer? Are you storing weights for your home gym? Or perhaps the assortment of items in a bedside table...

While all joints are not created equal, lets keep a sense of humor and willingness to see the beauty in simplicity.

pdxwoodsman

Portland Oregon

I think that the dovetail joint - and its variants - represent a high level of craftsmanship. I was in Egypt a couple of years ago, and I don't remember seeing any dovetails (maybe the drawers were closed), but I do remember seeing scarf joints on the Pharaoh's funeral boat - held together with rope and pitch. I also remember seeing something that looked a lot like pocket hole joinery - probably without metal fasteners. Fundamentally, though, it is nice for a piece of furniture to meet its functional requirements and also look beautiful with doors and drawers open and closed.

That said, I would like to be able to do a good dovetail joint. It's on my list of needed skills. I envy those who can do really good joinery, dovetail or not.

Woodworking requires many decisions in the building of any project. Skill levels vary widely between woodworkers. It seems to me that dovetails are one choice among many, and can be used for strength, aesthetics, or to showcase ones skill level. Whether machine made, or hand cut, I appreciate a dovetail joint. Many of those commenting seem to be unable to make dovetails, or unwilling to put in that much effort. If woodworking is a hobby with no stress allowed, or a passion for excellence, let each decide for themselves. But let's not let the neophyte ridicule the true craftsman. Quality is quality and should be appreciated by those of us who dare call ourselves, "Woodworkers!"

For years I suffered from dovetail guilt. My dirty little secret was, I don't know how to make 'em and I'm afraid to try. Then , at a woodworking show, I watched a demo where a guy eyeballed and hand cut a bunch of pins with only a baseline marked out. No other layout. He just started cutting pins, chopped them out and marked them against the second board with a pencil. In no time at all he had a joint tapped together with no glue that I couldn't pull apart. I was impressed. I went home and found my extra thin saw with no set that I use for cutting off dowels. Using it as a pull saw I started joining every scrap and cut-off in the shop. Every day I cut four or five. No agonizing, no measuring, just knock 'em out and try again. They started to get better. Some of them I couldn't pull apart. This was fun. I bought a good saw and started measuring and doing real layout. I got better. Sometimes I cut out the tails and left the waste, but it was a learning experience and no expensive wood was lost and no project ruined. I never have to do big production runs of multiple drawers because I'n not in the business, but when I need a few drawers for a table or a work bench I think it is faster to make dovetails by hand than setting up to make them by machine and a lot more fun. Just my 2 cents.

Since that's my desk at the top of this post, I think I ought to maybe say something here. What, I'm not sure ....Here goes ... I wrote the post on the curved front drawers on my blog two years ago and it was a result of trying to make dovetails on curved drawer fronts. Not easy,imho, not worth it. Mark Granfors and I came up with the pegged solution described in the post. It's appropriate for that instance, not appropriate for all instances. The trick is knowing where and when to use each technique that you have taken the time to figure out. We can cut dovetails ... some of us in our sleep ... See this post ...

http://dorsetcustomfurniture.blogspot.com/2009/11/make-box.html

and sometimes a nailed rabbet on commercial slides is the winner. Use them all. Don't judge. As the man said in 1692 ... 'Be careful...Strive to be happy'

Happy Thanksgiving ... Thanks for all your interesting comments. Dialogues and stories keep us engaged ....

Some time ago I worked in a small town hospital. The facility was built 40 years earlier by local tradespeople, many of which I had the pleasure to meet over the time I worked there. At one point I helped our maintenance guys demo a couple of wooden door frames in preparation for a remodeling project. Much to my surprise, the frames were assembled with dovetail joints and no nails, save for the trim. As an amateur woodworker, I was impressed and felt quite guilty tearing out someone else's craftsmanship.

Matt Kenny writes a blog entry in which he creates his own contorversy and insults the woodworking community to fire up his contrived argument.

Fine Woodworking's weekly newsletter drives a huge amount of traffic this way.

There is an advertisement a click away where you can buy a DVD on drawermaking.

I think Matt underestimates his audiance. Fine conversation on a topic can be had (as evidenced in some of the great responses here) without manipulating your readers/subscribers.

Will you play upon this pipe?

Dovetails have the major advantage of being mechanical strong and most of all are glued to the grains and not to end grain, therefore a very strong joint. Pinned rabbets are well crafted and are impressive, but not as strong as dovetails. Had they been finished with staples or nails rather than dowels, they would be called "shoddy."

When I checked some drawers on old furniture (70+ and +++ years) half of it was dovetailed the other half was nailed. Be it cheap models in painted hardwood or more expensive carved wood.

Can one actually believe that using a dovetail joint is the dividing point between a fine piece or not? If so then buy yourself a $25 dovetail bit for your router and you - YES YOU!!! are a fine wood worker. Since when does one joint define you as a person, as a woodworker? The answer is when you need a badge a reason to beat your chest, a reason to draw a line in the sand. A beautiful piece thats lasts generations, draws attention, and makes the user feel alive far surpasses the makers ego. A dovetail drawer is nothing compared to the love that is evident viewing the piece, the love of making the piece, before a drawer, if used is opened. Put you heart, soul, and life into your work - this will be felt and maintained long after the obligatory nod to dovetails (if at all). The purists are still using hide glue and hand cut dovetails.

Thanks to Fine Woodworking for the article.

Rich