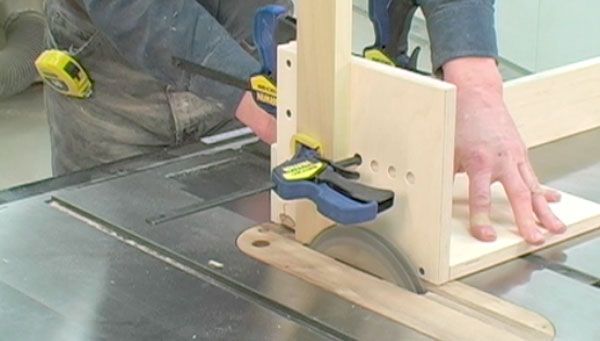

Tablesaw Tenoning Jig

Make this tenoning jig with a few clamps and some scrap plywood. See how in this members-only video.

Designed by John White

Don’t go out and buy an expensive tablesaw tenoning jig, John White designed this basic jig using some scrap plywood and three quick-release clamps. See how it works in this members-only video.

Or, for other styles of tenoning jig, see this animated display on a multiuse joinery jig (it includes a tenoning fixture) or a dedicated tenoning jig using phenolic plywood.

Comments

Bad idea. I don't want a steel bar clamp anywhere near a spinning table saw blade. We cut perfect tenons on the bandsaw - in complete safety with almost no setup time. The bandsaw tooth marks left on the tenon faces provide extra mechanical lockup for the glue joint.

I agree with OF, having the clamp over the blade is scary and dangerous. Why can’t the clamp be reversed so the camping mechanism is over the base - the other clamps may have to be repositioned. Also, route a horizontal slot in place of the holes. Make the slot just slightly wider than the clamp bar so the clamp cannot rotate. I also use a bandsaw for cutting tenons.

OF you are being unfair to him. What if we don't have a band saw first of all. secondly considering one does'nt have a band saw it's a cheap and quick way to do them.

As long as we're careful and taking your time. The clamps should'nt be a problem.

It's alright on maybe giving a tip on how to improve his jig. Such as LarinUP wrote to reverse the clamps and so on. But we can do without the critisism.

I like the simplicity of the jig. The clamp location makes me uncomfortable too. Another alternative is to make the stop block a little wider and cut a slot slightly wider than the clap bar and diagonally downward at about 45 degrees. Make the slot deep enough so that the clamp engages the work piece well. Then the clamp that holds the work piece and is back from the blade.

With respect to OF-the idea you pose is probably correct however the dimensions of that jig are such that the blade cannot reach the bar. In the picture it shows nearly all of the blade is exposed and it is just half way up to the point of the clamp. That's my input.

Log in or create an account to post a comment.

Sign up Log in