It’s quite likely you’ve never heard of thermally modified wood, but the process makes common wood species take on a whole new look and the color change goes all the way through. It’s available in 4/4 to 8/4 thickness. Thicker blanks for turners are also available. The heat-treating process warms the wood from 185°C to 212°C (depending on the species), which changes the color and improves its decay resistance.

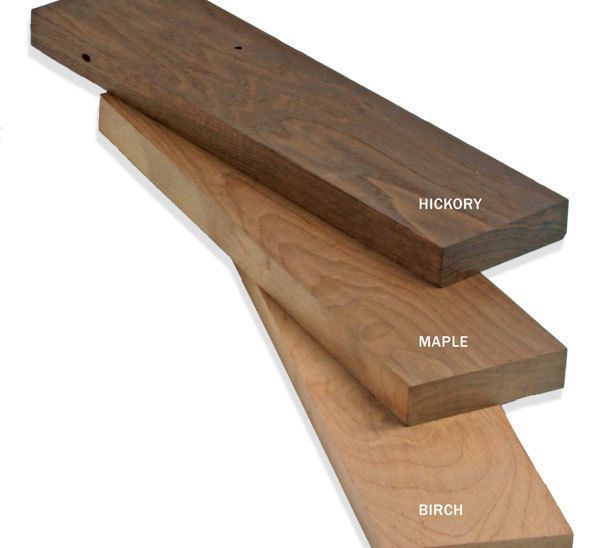

After treatment, hickory and ash have color closer to exotics like ipé and wenge. Maple takes on a walnut hue. Oak takes on a fumed look, while birch, alder, and aspen take on a reddish color closer to cherry. Although heat-treating makes the wood decay-resistant (equal to red cedar), it does little to protect it from the sun, so you’ll want to treat outdoor projects with a UV-resistant finish or the material will gray.

Thermal modification adds about a dollar a board foot to the lumber’s normal cost, excluding shipping. Contact seasonwood.com for further details.

|

Fume-free oak. This box looks like it’s made from fumed or stained oak. Actually, the oak has been heat-treated, a process that darkens the wood throughout its thickness and makes it resistant to decay. |

Fine Woodworking Recommended Products

DeWalt 735X Planer

AnchorSeal Log and Lumber End-Grain Sealer

Ridgid R4331 Planer

Log in or create an account to post a comment.

Sign up Log in