Essential Push Sticks

Safety aids for the tablesaw and router keep your fingers away from moving bits and blades

At the Center for Furniture Craftsmanship, where I teach and also manage the woodshops, showing students how to safely operate power equipment is one of our first tasks. The lesson always includes push sticks.

A push stick is a shaped length of wood or other material that helps control the movement of a workpiece. It is most needed at the tablesaw, jointer, router table, and bandsaw. Using a push stick keeps hands away from blades and cutters. It also helps maintain an even pressure and feed rate, reducing the risk of kickback and producing a smoother cut. In our shops, we keep extra push sticks handy, and there is always one sitting on top of a machine table or hung on a hook nearby. We encourage students to get in the habit of looking for the push stick before they turn on the machine.

|

|

Make your own push stick

There are many well-designed push sticks for sale, but shopmade versions are easy and inexpensive to make from scrap. A well-made push stick will hold the work securely with a notch, cleat, or nonslip surface. It will feel right in the hand—an awkward handle can be unsafe if it forces you to shift your hand for a better grip. And it will be easy to make, because shopmade sticks are meant to contact the blade at times and eventually to be replaced. Here’s a look at a variety of shopmade push sticks in use where they’re needed most.

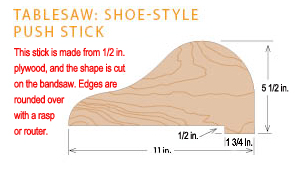

CLICK IMAGE TO DOWNLOAD A PATTERN

(Requires Adobe Reader)

Safe ripping on the tablesaw

Safe ripping on the tablesaw

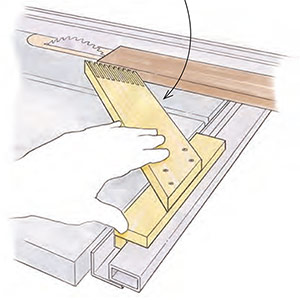

When ripping stock on the tablesaw, a workpiece that is not properly guided through the cut can veer into the back side of the blade and be kicked back at the operator. And when ripping narrow stock, the fingers can come too close to the blade, leading to tragedy in an instant. For these reasons, we teach students to use a push stick when ripping to widths of 6 in. or less.

Shopmade push sticks are easily replaceable, which means you can drive the push stick into the blade if the cut requires it. Just be sure to keep the push stick parallel to the fence and be prepared for increased resistance as the blade cuts through the bottom of the stick. Also, be aware of the blade height to make sure your fingers are well out of the way of the blade.

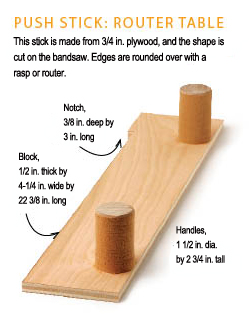

Routing safe and sound

Routing safe and sound

Occasionally, you might need to rout an edge profile on a narrow workpiece using the router table. Featherboards will help hold the piece firmly to the table surface, but you’ll need a push stick to guide the work snugly against the fence.

An effective push stick for the router table is a simple piece of plywood with a notch cut into one end. Two large handles at each end make it easy to grip and allow you to safely pass the workpiece past the spinning bit.

Photos: Steve Scott

Fine Woodworking Recommended Products

Shop Fox W1826

Hedgehog featherboards

Rockler Dust Right 650 CFM

Comments

The link to PDF pattern dosn't work!

As reported by someone else more than 5 years ago, the link doesn't work. argh, doesn't anyone read these comments?

Log in or create an account to post a comment.

Sign up Log in