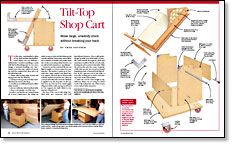

Tilt-Top Shop Cart

Move large, unwieldy stock without breaking your back

Synopsis: Fred Sotcher had a specific list of tasks he wanted his materials-handling cart to perform. Here, he offers detailed project plans and directions on how to build this handy, versatile shop accessory. The cart not only helps move heavy, unwieldy stock, but also doubles as a bench surface and tablesaw infeed/outfeed table, and it can be stored conveniently out of the way.

The first time I manhandled a sheet of 1-in.-thick medium-density fiberboard (MDF) onto my tablesaw, I realized that I needed something to assist with this backbreaking task. So I set out to design a materials-handling cart. But I wanted more than just a plywood mover. My wish list required this shop aid to do the following tasks:

- Assist with feeding large boards and sheet goods onto the tablesaw

- Transport sheet goods and other materials from my truck to the shop

- Double as an additional bench surface when needed

- Act as a tablesaw infeed/outfeed table

- Store conveniently out of the way

It’s safe to say that the cart I created meets all of those requirements. The tilting top makes it easy to load and feed sheet goods onto the tablesaw. Heavy-duty casters allow me to wheel it around the shop easily. And it also works as an independent bench or as an outfeed table extension to my tablesaw.

I wanted a top that remained flat yet was light in weight, so I chose torsion-box construction. The interior is made up of 3-in.- wide pine strips stapled and glued into 5-in. squares. The box then is framed with a thicker hardwood and the two sides are covered with Masonite. Pressure laminate is applied over the Masonite on the top. Two 1 ⁄8-in. by 12-in. by 12-in. metal angles (Simpson 1212L), with one leg cut off each at 7 in., support the shelf, which is constructed of hardwood.

The base of the cart is built using 1-in.- thick MDF and connected with 1 ⁄4-20 knockdown fasteners. (You could probably get by with 3 ⁄4-in.-thick MDF.) A 3 ⁄4-in.- dia. shaft extends through the table and terminates in pillow blocks at both ends, forming the pivot point for the table. With the pivot point near the center of gravity of the sheet goods, you can pivot several hundred pounds of material with little effort. At the opposite end of the table, a 3 ⁄8-in.-dia. locking pin is used to lock the top in the horizontal position.

I made the cart the same height as my tablesaw. When I’m not using it to feed stock, it fits behind the saw, where it acts as an outfeed table extension.

From Fine Woodworking #160

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Woodriver Rechargeable Desiccant Bag

WoodRiver Router Bit Storage Case

Log in or create an account to post a comment.

Sign up Log in