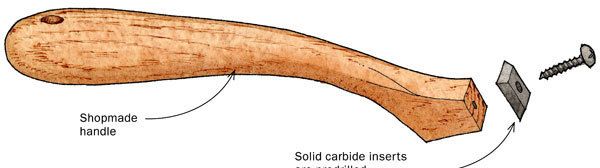

Durable Carbide Scraper Reaches Tight Spots

I make scrapers using 3/4-in.-sq. carbide inserts for machining metal. These scrapers excel in corner and edge work because the scraper head is small enough to get into tight areas.

The solid carbide is sharp, long-lasting, and maintenance-free. These carbide inserts, which come in different shapes and sizes, have a predrilled mounting hole and feature four separate sharp sides on the same blade.

Screw a blade to a homemade handle and you’re ready to scrape. Angle or skew the blade if you wish. Although sharpening a dull carbide blade is next to impossible unless you have the right diamond hones, one carbide cutting edge will last a long time if you are scraping only wood and wood glue. Steel scrapers, on the other hand, constantly need tuning up.

I’ve been using the same four-sided carbide insert blade in one of my scrapers for three years. You just cannot kill one of these tools.

To buy the carbide cutters, go to Woodworker’s Supply. Look for cutters intended as replacement knives for Freud flush-trim bits (catalog Nos. CG12 and CG13); you also can use four-sided inserts for a jointer cutterhead (115-001).

Updated: 4/2/2008 with information for Woodworker’s Supply (www.woodworker.com), not Carbide Depot as we originally listed.

Drawing by Jim Richey.

Drawing by Jim Richey.

Fine Woodworking Recommended Products

MicroJig Matchfit dovetail clamps

Bessey K-Body Parallel-Jaw Clamp

Log in or create an account to post a comment.

Sign up Log in