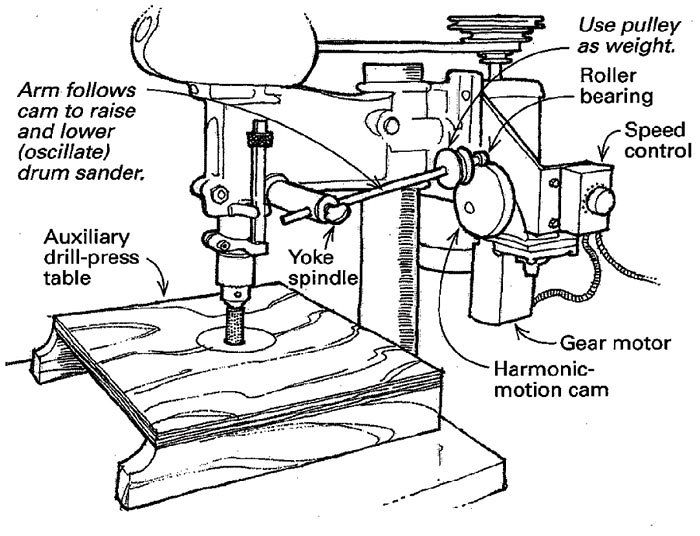

The oscillating spindle-sander attachment for a drill press described in Fine Woodworking #109 appears to be a good substitute for a benchtop sander. I built a similar, less expensive version that I’ve been using for more than 20 years. The attachment uses a gear motor to drive a harmonic-motion cam (a circular disc rotating off center), which raises and lowers the quill by means of a follower arm. I made the cam from 1/2-in.-thick Garolite, a dense thermoset plastic, which looks like tempered Masonite. Aluminum or even hardwood could be substituted. The follower is a steel rod that fits in the feed-yoke hole in the drill press. It is fitted with a roller bearing that rides the cam. Sandwich the bearing between thin brass washers, and hold it in place with a slotted-head machine screw. Fasten a weight to the rod (I used a cast-iron pulley) to counteract the spindle-return spring so that the follower rides firmly against the cam as it revolves.

My gear motor is a forerunner of the current Dayton model 2Z803, 1/15 hp, 100 rpm. I reduce the motor to a workable rpm with a speed control. Other slow-speed or variable-speed motors could be used. No matter what motor is used, the only ingenuity required in this setup is in devising a mount for the motor that puts the cam in the right position for the follower arm.

William E. Slaby, Royal Oak, Mich.

Fine Woodworking Magazine, August 1995 No. 113

Fine Woodworking Recommended Products

Hedgehog featherboards

Woodriver Circle Cutting Jig

Incra Miter 1000HD

Log in or create an account to post a comment.

Sign up Log in