Synopsis: Carver Robert L. Butler offers novices an outline of which tools to get to start carving (hint, don’t break the bank), what size project to tackle, and photos of what the tools can do. It’s not so much an instruction piece as a guide to how to get outfitted prior to learning how to carve. He does clarify that different types of carvings (animal shapes, musical instruments, etc.) require different types of gouges and other tools.

Furniture makers have recently become aware of the role of sculpturing in fine woodworking. The sculptured furniture pioneered by Wharton Esherick and recently developed by Robert C. Whitley and others uses carving as a design essential to accent light and shadow, and to form such functional elements as handles and pulls. Some craftsmen have branched out into wood sculpture as art. They start with a background and feeling for wood that trained artists often lack. But for whatever reason, a craftsman who develops an interest in carving is faced with the problem of acquiring suitable tools.

Too frequently, the craftsman new to wood sculpture buys a set of carving tools that does not meet his needs. He should be guided by the principle he followed in equipping his shop: buy a rudimentary set and add to it as experience and knowledge increase. Since most suppliers of woodcarving tools carry at least 100 shapes and sizes, it is impossible to make specific recommendations without knowing the type, style and scale of carving he plans to do.

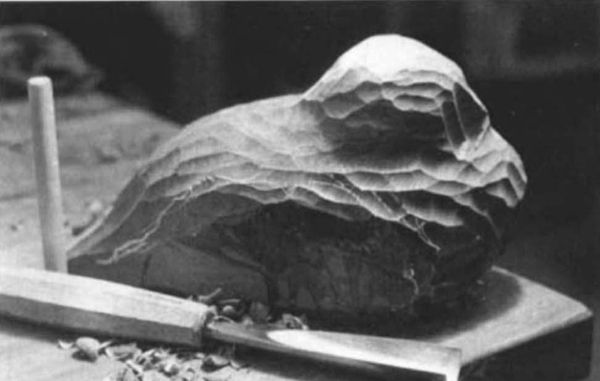

But without some guidance, the novice may not know where to begin. I feel that sculpture of moderate size provides a realistic starting point for beginners, especially for craftsmen who intend to sculpture furniture. I have arrived at this opinion through some early false starts and later during five years of teaching woodcarving and sculpture in local adult education courses. Small, intricate carvings do not provide the experience in line, movement and form that can be transferred to sculptured furniture.

For moderate-sized sculpture, I recommend five basic tools, plus a hard Arkansas slip stone to sharpen them. They are (1) a straight gouge with a cross-section curvature of #9, #10, or #11 and 25 to 30 mm. wide, (2) a smaller straight gouge, #5, #6, or #7 and 20 to 25 mm. wide, (3) a cylindrical Surform tool, (4) a fine-cutting wood rasp, and (5) a mallet. The first four will total about $30, and the mallet can be turned from any heavy hardwood such as maple or osage orange. A mallet could instead be cut from a branch and the handle roughed out on the band saw. The carver’s mallet is preferable to the carpenter’s mallet which is used to make mortises, because it carries more weight in the head and be cause its cylindrical form gives the hand only a glancing blow when it misses the handle of the carving tool. There is much less damage to the knuckles.

From Fine Woodworking #4

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Marking knife: Hock Double-Bevel Violin Knife, 3/4 in.

Tite-Mark Marking Gauge

Veritas Wheel Marking Gauge

Log in or create an account to post a comment.

Sign up Log in