Synopsis: Furniture construction can be broken into two main categories: carcase and frame. In carcase construction, boards are joined end to end using dovetails, tongue-and-groove joints, and the like, as in a drawer or hutch. But it’s difficult sometimes to know which joint to use. Tage Frid chooses the strongest but easiest joint to construct, avoiding over-constructing a piece. Here, he discusses joints at corners, making lock miters, spline miters, and multiple-spline joints, finger joints, and joints that don’t meet at corners. He explains full-blind dovetails and hand-cut sliding dovetails. He closes with information on inserting backs on carcases.

Furniture construction is broken down into two main categories: frame and carcase. In frame construction, relatively narrow boards are joined—usually with a mortise and tenon joint—as in a chair or table base, or in a frame and panel door. (See Fine Woodworking, Summer 1976.) In carcase construction, boards are joined end to end using dovetails, tongue-and-groove joints and the like, as in a drawer or hutch. When designing a carcase, the beginner may find it difficult to know which joint to choose. Some joints are excellent in plywood but weak in solid wood, and vice-versa. Many beginners are so concerned with the “craft” aspect that they design in the most complicated techniques. They use a complex joint where a joint easier to make would work just as well. I always choose the strongest but easiest joint to construct. I cannot see spending time over-constructing a piece. And I expect my furniture to last long after I do.

Most carcase joints can be made by hand, but are usually more easily and precisely made on a circular saw. I would advise people who don’t own a circular saw to buy a table saw and not a radial arm saw. The latter is limited in function and not as accurate or flexible. It was designed for cross-cutting rough lumber to lengths, and even then is limited to a certain width. Many of the joints described here would be dangerous and impractical to make on a radial arm saw. I prefer at least a ten-inch table saw, and it does not cost that much more than an eight-inch. Buy one with at least a 1-hp motor, as an underpowered machine is much more dangerous to work with.

Joints at corners

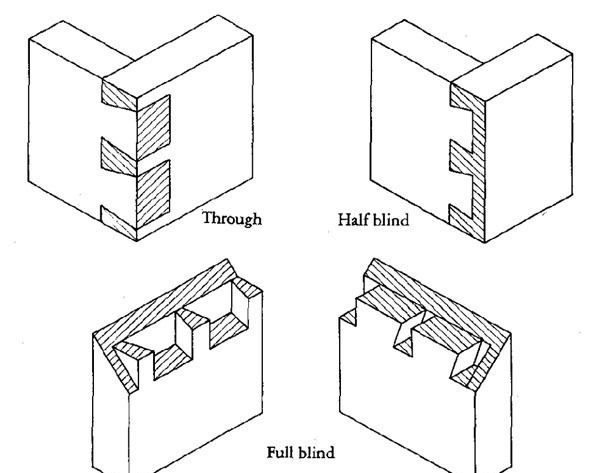

In the article on dovetails, (Fine Woodworking, Spring 1976), it is stated that dovetailing is one of the strongest and most attractive methods of joining the ends of boards together. This is true if you are going to make joints by hand. But most carcase joints lend themselves to machine fabrication. The closest machine joint to a dovetail is a finger or box joint. Because of the greater number of pins and the resulting total glue surface, it is stronger than a dovetail, far easier to make, and just as attractive.

From Fine Woodworking #5

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Festool DF 500 Q-Set Domino Joiner

Bessey EKH Trigger Clamps

Estwing Dead-Blow Mallet

Log in or create an account to post a comment.

Sign up Log in