Synopsis: Tommy Bargeron talks about why he thinks the shaper is one of the most useful machines in a serious workshop. He uses it for machining edges, moldings, and lippings, and it’s faster, more efficient, and more versatile than a router or handplanes, he says. To extend its usefulness, Bargeron explains how to use shaper collars to hold pairs of flat knives, which can easily be ground to almost any profile. He details how to do this, including information on adjusting spindle speed and adding a spindle lock. He also explains how to make a jig to hold knives for grinding, and he includes safety information. Photos illustrate the details.

The shaper is one of the most useful machines to have in the serious workshop for machining edges, moldings and lippings. Only the router or a set of hand planes can even attempt to do the type of work the shaper can do, and they are no match for its speed, versatility and efficiency.

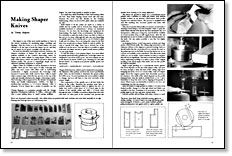

For most woodworkers and antique restorers, however, the shaper’s usefulness is limited by the small selection of patterns available in the common three-wing cutters. Its range can be made infinite by using shaper collars to hold pairs of flat knives, which can easily be ground to almost any desired profile. The process is surprisingly simple and no elaborate grinding equipment is required.

Shaper collars are available in various diameters to fit most spindles. There are two basic types of collar, lock-edge and plain, and each comes with either solid or ball-bearing construction. I highly recommend the lock-edge collar because it is much safer. Knife steel for these collars is made with a serrated edge, which fits into grooves in the top of the collar and virtually eliminates the danger of throwing a knife. The lock-edge collar is approved by the federal Occupational Safety and Health Administration (OSHA). On light to medium-duty machines, a 2-1/2-inch diameter collar is adequate. If your shaper has a variety of spindles use the largest. An extra long spindle is helpful at times.

In a small shop where flexibility is vital, ball-bearing collars are best. They make shaping curved work safe and easy, because the stock can ride directly on the bearing. Ball-bearing collars cost about $100; plain collars are available for $60.

Knife blanks to fit the collars are made in a variety of widths and are usually sold in 24-inch bars. Shaper steel is available hardened or unhardened; I always use hardened because I do not have the knowledge and equipment for heat-treating. The depth of the cut determines bar thickness. It is advisable to make the knife at least one-third as thick as the cut is to be deep. Although this ratio can vary depending on spindle speed, wood density and so on, it is better to play it safe and not skimp. If you are trying this setup for the first time, buy several precut shaper blanks in various widths. Be sure to specify lock edge. Later, buy a 24-inch bar of the width you use the most. Note also that it is possible to grind both ends of a blank, and also to grind several narrow profiles on one wide blank.

From Fine Woodworking #5

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Fein Turbo II HEPA Wet/Dry Dust Extractor

Festool DF 500 Q-Set Domino Joiner

Festool Rotex FEQ-Plus Random Orbital Sander

Log in or create an account to post a comment.

Sign up Log in