The Bowl Gouge

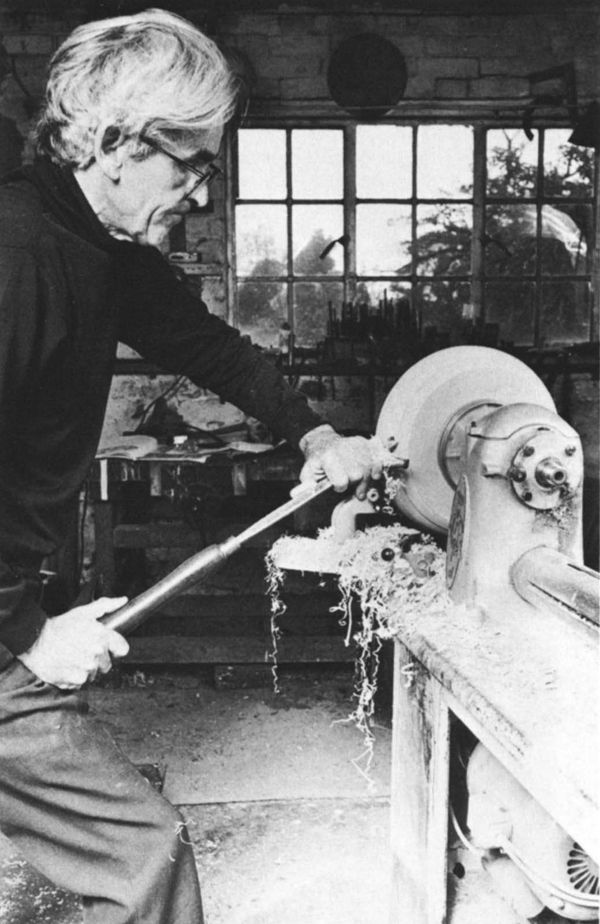

Using long-and-strong tools to turn the outside

Synopsis: There are three types of woodturning gouges, writes Peter Child: one designed for bowls, one for between-center coving and small rounds, and one for roughing square stock to cylinders and sweeping curves, also between centers. He describes how they differ and what they’re best used for. Child explains how to reshape the bevels of your new tools and how to cut with them. You’ll learn the correct stance, how much weight to put on the gouge, and how to avoid unpleasant surprises, such as when the gouge digs in, gashing the wood. His instructions include tips for left-handers, too.

Woodturning gouges are of three types: one designed for bowls, one for between-center coving and small rounds, and one for roughing square stock to cylinders and sweeping curves, also between centers.

The blade of a bowl gouge is always “long and strong,” meaning heavy duty. A good new one measures 12 in. from cutting edge to tang. It has a deep U-shaped flute with much meatier metal at the bottom, or keel, of the flute than at its two wings. Bevel angle varies with how tall a person the turner is, but it is always less than 45 degrees, although not so small as to make the edge fragile. There is no second bevel as in a bench chisel or plane iron, and there is no point. The edge is shaped square across.

Four sizes of bowl gouges are in current production: 1/4 in., 3/ 8 in., 1/2 in. and 3/4 in., ranging in weight from 4 to 16 ounces. Each size has a particular function. The 3/4-inch is absolutely the largest that can be used correctly; any bigger gouge is not a bowl gouge, however long and strong it may look. The heavy-duty handles should be about a foot long, and hefty—weight and length are necessary for control. This is why bowls should be turned outboard and should not be attempted between centers, where the lathe bed restricts movement of the gouge.

Coving gouges, for between-center work, are of medium strength and have a longer bevel and a lighter handle than bowl gouges. They also have pointed, “lady fingernail” noses and a much shallower flute. Common sizes range from 1/4 in. up to 3/4 in. The roughing-down gouge serves for larger work.

Roughing-down gouges are of medium strength, deeply throated, semicircular rather than U-shaped in cross section, beveled at 45 degrees, and of even thickness. Their lack of keel makes them unsuitable for bowl work, whatever the size. They range from 3/4 in. up to 1-1/2 in.

Depending on the mood of the factory grinder, the bevel of a new tool can be any angle or length at all, and so the purchaser will have to reshape it. Any point must be removed so the edge is straight across. The bevel should be hollow ground right up to the cutting edge, without a second bevel. A skilled operator can thus provide himself, straight from the grindstone, with an edge that has a fine sawtooth cutting burr. Such an edge would horrify a cabinetmaker or carver, but it is most practical for a turner as it can be resharpened in seconds on the grindstone. An absolutely flat bevel does the same job as one hollow ground, but takes longer to obtain and maintain with a flat stone.

From Fine Woodworking #5

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Estwing Dead-Blow Mallet

Dividers

3M Blue Tape

Log in or create an account to post a comment.

Sign up Log in