Synopsis: William Keyser, Jr., says the distinct advantage of steam bending is that the grain of the wood follows the curve, thus eliminating the short-grain problems associated with bandsawn curves. He outlines its shortcomings, too, and tells you how to decide whether to steam-bend or laminate. Keyser explalins how to prepare a steam bath for your stock, how to select wood that bends better than others, how to prepare the stock, and which straps and molds work best. He explains how to bend in one plane, how to learn from failures, and how to perfect bends without a strap. He closes with a few notes on complex curves and how to bend off a corner.

Ever wonder how old bentwood furniture parts were made or how ribs for boats are formed? Probably by steam bending. This process uses steam or boiling water to plasticize the wood so that it can be bent, usually over a form or mold. Upon cooling and drying, the bent piece retains its shape. The distinct advantage of steaming is that the grain of the wood follows the curve, thus eliminating the short-grain problems associated with bandsawn curves.

Of course a lamination, i.e., several thin pieces glued together in the curved position, will also do the job. But there is something nice about one integral piece of wood making the bend, with the grain following the curve. The time required to resaw and surface all the laminations is saved, no wood is lost to saw kerfs and ugly glue lines don’t surface if the bent piece is subsequently carved or shaped. Also, a lot fewer clamps are required.

Steam bending has shortcomings. The most troublesome is accurately predicting springback. A laminated member will conform very closely to a mold; the greater the number of laminations, the less it will spring back. In steam bending the results depend upon the grain structure of each piece of wood. Local eccentricities—knots, checks and cross grain— will affect the final curve much more than in lamination, where the process itself tends to homogenize the structure of the member. This disadvantage becomes critical when exact duplicates must be made. Also, some breakage or rejects can be expected in steam bending. If ten pieces are required, bend twelve or thirteen.

When deciding whether to steam-bend or laminate, reason it out this way: If the member must start precisely at some point A, negotiate a specific curve and end up exactly at point B, and do so repeatedly, the odds are better if you laminate. If the relative positions of A and B are not critical, or if their relationship is maintained by the rest of the structure and if there is some tolerance in the path taken from A to B, then the integrity of a single piece would justify steam bending. Where either process is appropriate, the material and time saved in steam bending by not resawing settle the question.

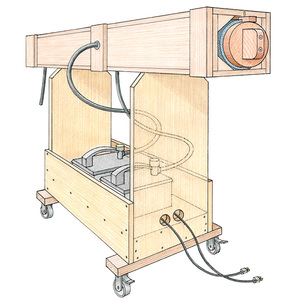

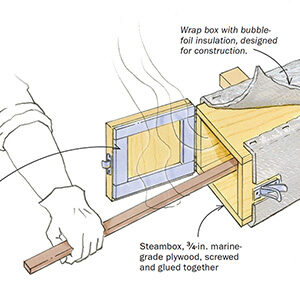

The piece of wood to be bent is placed in a closed container or steam box and bathed in steam generated by boiling water. The steam gradually softens the structure of the wood and makes it flexible.

From Fine Woodworking #8

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Ridgid EB4424 Oscillating Spindle/Belt Sander

Log in or create an account to post a comment.

Sign up Log in