Synopsis: Many woodworkers are confused about commercial lumber grading. A bewildering assortment of grades confronts the buyer. There are different standards for hardwoods and for softwoods, and the rules make exceptions for certain species like walnut. In this article, William W. Rice, a professor of lumber grading, explains what lumber grading attempts to do, the history of classifying lumber, how American standards work, and how lumber is judged. Then he details how softwood and hardwood grading works, and how to select lumber.

When I hear a woodworker exclaim, “How can that board be a Select? It has a knot as big as your fist!” I sympathize with his frustration. But I also know that he, like many, is confused about commercial lumber grading. A bewildering assortment of grades confronts the buyer. There are different standards for hardwoods and for softwoods, and the rules make exceptions for certain species like walnut.

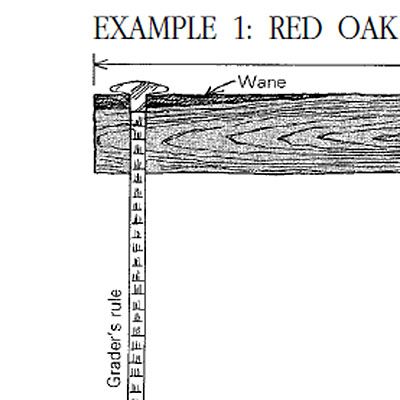

Lumber grading is a way of evaluating the usable lumber in a board. It takes into account the number, size and degree of defects, and the number and size of clear pieces that will remain when the defects are cut away. But not every project needs a perfect board 12 ft. long. Once a cabinetmaker learns his way through the intricacies of the grading system, he will be able to select the most suitable lumber for the job at hand. He may well find that he can cut the size pieces he needs from No. 1 Common as well as he could from Firsts and Seconds—at considerable saving.

As far back as the early 1700s the need for classifying lumber by grades was recognized. Originally, appearance was the primary requisite, but with increased knowledge about wood properties and methods of utilization, lumber grades now also take into account strength characteristics and yield potential. Modern lumber-grading rules provide standards for the manufacture of the same product by different mills. They also serve as common specifications both buyer and seller can use to determine that full value is received and sold.

In the United States, the American Lumber Standards Committee (ALSC) of the Department of Commerce is responsible for general establishment and administration of lumber grades. Application and enforcement of specific grading rules are the responsibility of various lumber inspection associations. For example, the California Redwood Association has jurisdiction over member mills and dealers handling redwood, and the Western Wood Products Association monitors the standards for several West Coast species, including ponderosa pine and Douglas fir. Some other associations are the Southern Pine Inspection Bureau, the Northeastern Lumber Manufacturers Association and the National Hardwood Lumber Association. Altogether there are about 15 associations that oversee the grading of wood products; each is represented on the American Lumber Standards Committee and all operate under its certification. Grading rules are voluntary standards set by the lumber industry through the ALSC, not dictated by the government.

From Fine Woodworking #13

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Festool DF 500 Q-Set Domino Joiner

AnchorSeal Log and Lumber End-Grain Sealer

Starrett 12-in. combination square

Log in or create an account to post a comment.

Sign up Log in