Synopsis: In this quick but informative article, R. Bruce Hoadley praises the dial indicator, usually associated with metalworking but routinely used in his shop for many jobs. He explains how the magnetic base model works and how the indicator comes with a universal-jointed arm that holds it in virtually any position relative to its base. When it is locked into position on a drill-press table, the trueness of quill rotation can be measured, and out-of-round, out-of-center, and bent shafts and mandrels of all kinds can be checked. Set up on a flat surface, it can check diameters and roundness of dowel pins, veneer thickness, and more.

From Fine Woodworking #24

An indispensable tool in our shop is a dial indicator with a magnetic base. Although this tool is usually associated with metalworking, we routinely use it for a host of jobs, from aligning equipment and setting up cutterheads to precise measuring of wood samples and deflection in joints.

The dial indicator works by coupling a plunger-type spindle through internal gearing to a sweep hand. When the instrument is held firmly in position, any slight in-and-out movement of the spindle results in greatly magnified movement of the hand around the dial. The spindle is lightly spring-loaded so its tip will follow variations in the surface it contacts, and it can be fitted with a variety of contact points for special situations. Our instrument has a full inch of spindle travel, and its dial is graduated in units of 0.001 in. Indicators are made with greater accuracy, but the trade-off is a smaller measuring range.

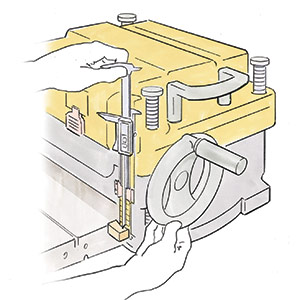

The indicator comes with a universal-jointed arm that holds it in virtually any position relative to its magnetic base, which can be demagnetized by the push of a button. When the button is “off,” the base retains only a whisper of magnetism, just enough so it will rest snugly against a steel surface. Once in position, the magnet is turned “on,” whereupon it locks with about 50 lb. of force.

When the base is locked to a drill-press table and the indicator positioned perpendicular to the quill, the trueness of quill rotation can be measured. Similarly, measuring against the shank of a drill will reveal whether the chuck is centered. Out-of-round, out-of-center and bent shafts and mandrels of all kinds can be checked this way. By setting the base on the outfeed table of a jointer, the height of each knife can be gauged, and measuring across to the infeed table will tell whether the two tables are parallel. A hand-plane iron could be set in the same way. The indicator is invaluable in setting the bedrolls, outfeed roll and pressure bar of a thickness planer. On a table saw, the indicator will measure tooth height as well as set. Of course, the machinery must be electrically disconnected and revolved by hand. Never attempt to gauge cutting edges at operating speeds.

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Estwing Dead-Blow Mallet

Dubuque Clamp Works Bar Clamps - 4 pack

Stanley Powerlock 16-ft. tape measure

Log in or create an account to post a comment.

Sign up Log in