Synopsis: Frank Klausz grinds damaged tools, new tools that have been incorrectly ground, and tools whose repeated sharpening has flattened the hollow grind. He shares tips here for faster, easier grinding and explains how his tool-rest angle helps as a guide. He explains how to grind a blade and when to dampen the metal. Photos illustrate his straightforward explanations.

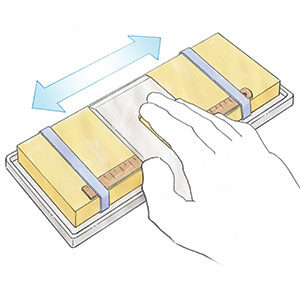

Grinding is the first step in shaping the bevel on a cutting tool. It makes the edge straight and square and puts the bevel at the proper angle. It is not necessary to regrind every time you sharpen; a properly ground edge can be honed many times. I grind damaged tools and new tools that have been incorrectly ground. I also regrind tools after repeated sharpening has flattened the hollow grind; it’s easier to hone a hollow grind. In my apprentice years, we did not use a motorized grinding wheel. We had a flat, rough whetstone about 8 in. by 4 in. by 3 in. that sat in a wooden basin with a couple of inches of water. I spent many hours at that stone, and every week the worst job in the shop was to change the water and clean out the wooden basin so you could see the bottom. Flat grinding on such a water stone and honing on a fine, grey stone produces the best edge, and it holds up longer than a hollow-ground edge, but if you have to remove a lot of metal, it takes a long time to do and a lot of sweat.

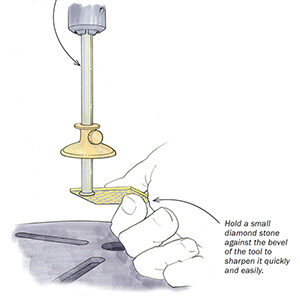

For faster, easier grinding, use an electric grinder with a 60-grit aluminum-oxide wheel, rotating toward you at 3,000 RPM. I prefer a 1-in. or wider wheel at least 6 in. in diameter. Wheels smaller than 4 in. in diameter give too deep a hollow grind. I keep the wheel clean and dressed with a carborundum block; a glazed stone will not cut well, and can overheat the tool. My grinder has a cover around the back of the wheel and a transparent shield on top. I get gooseflesh when I see a grindstone spinning freely with no cover and no safety glass for the operator. Protect your eyes.

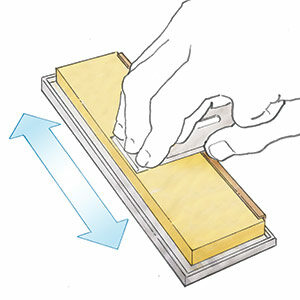

My grinder also has a standard tool rest whose angle and closeness to the wheel are adjustable. But I never change it. The only part of the tool rest I use is the lower edge, as a guide for my right index finger. The tool need not lay flat against the surface of the tool rest. If it did, you’d have to adjust it for each tool, depending on the steel and the work. Less dense woods require more acute angles, and hard steel can hold its edge ground to such smaller angles. Chisel and plane blades should be ground to 25° or 30°.

From Fine Woodworking #29

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Ridgid EB4424 Oscillating Spindle/Belt Sander

Veritas Standard Wheel Marking Gauge

Tite-Mark Marking Gauge

Log in or create an account to post a comment.

Sign up Log in