Synopsis: Gluing up is an irreversible, one-shot deal. Ian J. Kirby says that to get the best results, you should have a table especially prepared for this purpose, its surface flat, clear of debris and well waxed. He advises dry-clamping your piece together first exactly as you would a glued assembly, checking for accuracy along the way. He offers a range of tips, and then breaks down each step for instruction specifically on bar clamps, glue application, edge gluing, mortise and tenon joints, alignment, face assembly, and carcase jobs.

From Fine Woodworking #31

Gluing up is unique among woodworking operations. It’s an irreversible, one-shot deal and has to be got right. You may have done accurate work up to this point, only to find that a small error in assembling or clamping has produced all sorts of inaccuracies that will be difficult, perhaps impossible, to fix. A common lament in woodworking is that “everything went perfectly until glue-up, then everything went wrong.” When you think about it, this is not surprising. How often do we systematically consider gluing up, and how much time do we give to dry clamping? Usually very little, and then halfheartedly.

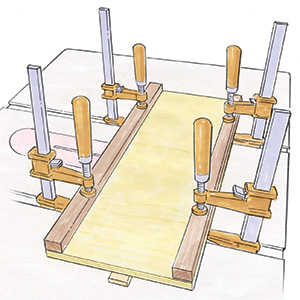

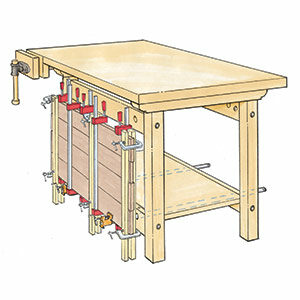

To get the best results, we should bring a studied method to this operation and practice it more. We ought to have a table especially prepared for this purpose, its top surface flat, clear of debris and well waxed to resist glue penetration. A piece of varnished plywood over your benchtop will do, but a sturdy table, 36 in. high with a Formica surface, is better.

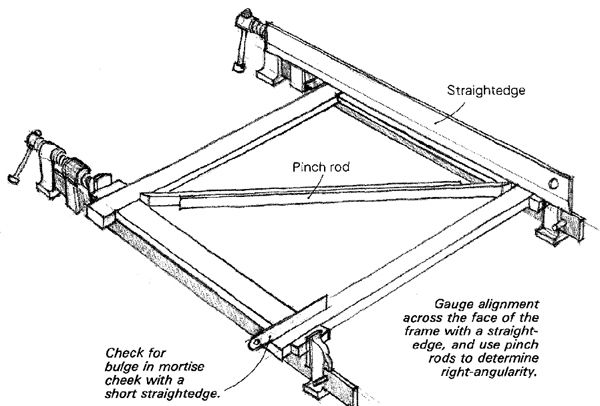

Before gluing up, you should dry-clamp each assembly exactly as you would clamp a glued assembly. This means positioning and tightening all the clamps, with correct glue blocks, and checking the whole assembly for accuracy. Gluing should proceed calmly, in an atmosphere of preparedness, with the glue and necessary applicators ready, clamps standing by, and you and your assistant decided on the order of events. The time of day you glue up is important. Most woodworkers like to glue up in the evening and let the glue set overnight. To meet this goal, a lot of work often gets rushed, dry clamping gets short-circuited and we have all the necessary ingredients for a disastrous glue-up—fatigue, unpreparedness and anxiety. The only reason to proceed under such conditions lies in the spurious notion that glue cures only while the moon is out.

Consider the alternative. Leave the work dry-clamped overnight. The next morning, check the clamping to see if everything is still properly aligned. Then collect all the tools and materials you need and begin to glue up. The light is better, your mind is fresh, the pressure to complete the job is gone. If you can’t leave the work dry-clamped overnight, at least let it sit for an hour while you attend to other things.

Gluing up actually begins with a decision about what to glue together and in what order. The more subassemblies you can get together, the easier the total operation will be, especially the final glue-up. But before gluing any parts, always clean and prefinish surfaces that cannot be reached later with a plane. It’s much easier to work on a piece of wood while its entire surface is exposed and accessible than to try to remove mill marks and other blemishes once other parts are permanently in the way.

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Bessey K-Body Parallel-Jaw Clamp

Dubuque Clamp Works Bar Clamps - 4 pack

Comments

sadly the last page of the pdf has become distorted.

Last page is unreadable.

Same problem with UK download, last page missing a lot of text. Hope you can replace the pdf.

Try again, it's showing fine here. Hopefully it was just a glitch. Let me know.

Hi Ben,

I just tried it again on 11/28/2020 and it is still unreadable. Sure nice if there could be a way to download that last page as this is such a fundamental article with such useful information. Thanks.

The pdf's last page, just downloaded, looks fine today: 2021-03-02

Still unreadable here. (iMac, OSX)

The last page is unreadable with MacOS Preview but is fine with Adobe's Acrobat Reader.

Log in or create an account to post a comment.

Sign up Log in