Synopsis: Unlike the ordinary marking gauge, whose steel scribing pin is designed to mark along the grain, the cutting gauge is equipped with a cutting spur, which should sever cross-grain fibers cleanly. This article explains where to find cutting gauges, which are not widely available today, how to make one for yourself, and how to use one by pushing it into the work. The author describes how to orient the cutter depending on whether you’re right- or left-handed, and how to use it as more than just a marking tool.

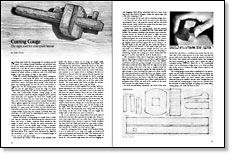

Nothing quite beats the cutting gauge for scoring across the grain. For striking dovetail baselines and shoulder lines for tenons, dadoes and rabbets, it’s an especially accurate and handy tool. It can also be used to eliminate splintering when crosscutting by scoring the wood prior to sawing, though this requires an initial crosscut to within an inch or so of the final length to give the gauge an edge to ride against.

Unlike the ordinary marking gauge whose steel scribing pin is designed to mark along the grain, the cutting gauge is equipped with a cutting spur, which when properly ground and honed, severs cross-grain fibers cleanly. Used across the grain, the marking gauge can tear the wood and produce a ragged line, but the cutting gauge incises a neat, clearly visible cut, just the right thing to accept the edge of a sharp chisel when paring away the last bit of end-grain tissue.

The only commercially available cutting gauge on the American market is made by Marples (England) and is sold by most mail-order tool suppliers for about $14. Usually made from beech, the fence has two brass wear strips let into its face, and is bored and tapped to receive a plastic thumbscrew which tightens against the stock and locks the fence in place at any distance from the spur. The Marples cutting spur is ground to a spear point and beveled on both skewed faces and is flat on the back. The spur is held firmly in the stock by a brass wedge. If you buy one of these or already have one, you’ll get it to work better by regrinding the spur to a round nose profile as described below.

Instead of buying a cutting gauge you might want to make one. Start by selecting and dimensioning the material for the fence and stock. A stable, relatively dense hardwood like maple or cherry will do.

From Fine Woodworking #32

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Starrett 4" Double Square

Stanley Powerlock 16-ft. tape measure

Olfa Knife

Log in or create an account to post a comment.

Sign up Log in