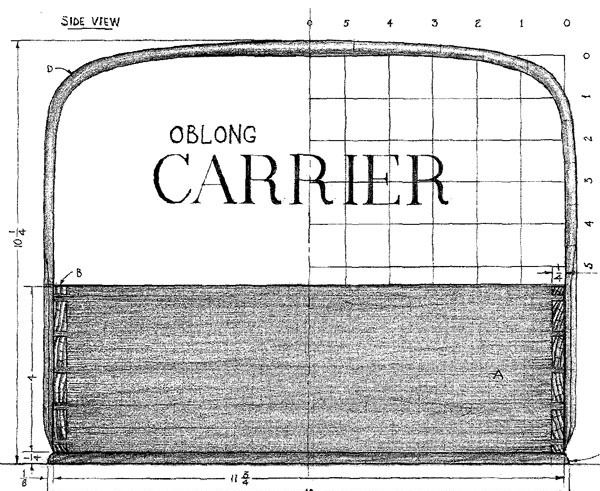

Synopsis: This short article with a scale drawing shows how to make a box fitted with a handle.

This not-so-difficult-looking project offers two challenges— the hand-cut, through-dovetail corners and the sculptured, steam-bent bail (handle). Carrier is the Shaker name for a box fitted with a bail. Those carriers that exhibit pleasing form, fine construction, and quality craftsmanship were made for the Shakers’ own use, whereas carriers made for sale in Shaker stores, though well crafted, look mass produced. With the exception of the manner in which the bail is fastened, this carrier is a fine example of one made for communal use.

To make the carrier, thickness-plane enough pine (wood species is optional) to make the sides (A), ends (B) and bottom (C). All surfaces should be hand-scraped and sanded. Those surfaces that will be on the inside of the carrier should be finished surfaces and so marked. Now lay out the sides and ends and add 1/32-in. to their widths and lengths, and cut accordingly. The extra length allows the ends of the dovetails to project minutely beyond the outside surfaces. After the sides and ends are assembled, these projections are planed or sanded off, resulting in a better appearing dovetail joint. The extra width is used for truing up the edges at the top and bottom of the carrier, again after assembly.

Mark out and cut the bottom 1/4-in. longer and wider than the overall length and width of the carrier sides and ends. Sand the inside surface and shape the upper edges as shown in the drawing. Nail the bottom in place—a nice touch here would be to use 7/8-in. fine-cut headless brads (available from Woodcraft, 313 Montvale Ave., Woburn, Mass. 01888).

Nailing the bottom onto the carrier sides may seem to contradict all we have been taught about wood movement, but it is the way the Shakers did it—and they had central heating too. It has been suggested that the bottom ought to be let into a groove in the sides, like a frame-and-panel. However, I have rarely seen good results from altering a Shaker design. In this particular case, inletting the bottom would eliminate a characteristic Shaker form, the molding created by the protruding bottom, and it would greatly complicate the carrier’s joinery. I think that when the bottom worked loose, the Shakers would just nail it on again.

The bail is made of ash; red or white oak or hickory could be used instead. Mill straight-grained stock to overall thickness, width and length (detail 2), then steam it and bend it around a mold before tapering it to shape. Although it’s difficult to shape the bail after bending, it’s more frustrating to lose a pre-shaped bail during the bending process.

From Fine Woodworking #32

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Ridgid EB4424 Oscillating Spindle/Belt Sander

Sketchup Class

Stanley Powerlock 16-ft. tape measure

Log in or create an account to post a comment.

Sign up Log in