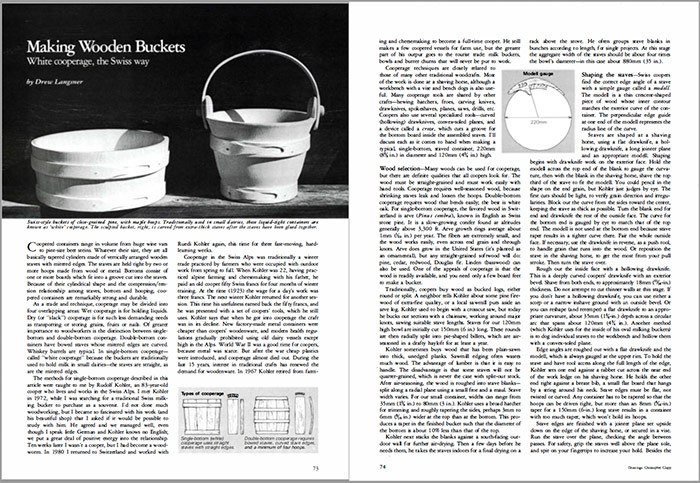

Making Wooden Buckets

White cooperage, the Swiss way

Coopered containers range in volume from huge wine vats to pint-size beer steins. Whatever their size, they are all basically tapered cylinders made of vertically arranged w09den staves with mitered edges. The staves are held tight by twO or more hoops made from wood or metal. Bottoms consist of one or more boards which fit into a groove Cut into the staves. Because of their cylindrical shape and the compression/tension relationship among staves, bottom and hooping, coopered containers are remarkably strong and durable.

As a trade and technique, cooperage may be divided into four overlapping areas: Wet cooperage is for holding liquids. Dry (or “slack”) cooperage is for such less demanding needs as transporting or storing grains, fruits or nails. Of greater importance to woodworkers is the distinction between single-bottom and double-bottom cooperage. Double-bottom containers have bowed staves whose mitered edges are curved. Whiskey barrels are typical. In single-bottom cooperage called “white cooperage” because the buckets are traditionally used to hold milk in small dairies-the staves are straight, as are the mitered edges.

The methods for single-bottom cooperage described in this article were taught to me by Rudolf Kohler, an 83-year-old cooper who lives and works in the Swiss Alps. I met Kohler in 1972, while I was searching for a traditional Swiss milking bucket to purchase as a souvenir. 1’d not done much woodworking, but I became so fascinated with his work (and his beautiful shop) that I asked if it would be possible to study with him. He agreed and we managed well, even though I speak little German and Kohler knows no English; we put a great deal of positive energy into the relationship. Ten weeks later I wasn’t a cooper, but I had become a woodworm. In 1980 I returned to Switzerland and worked with Ruedi Kohler again, this time for three fast-moving, hard-learning weeks.

Cooperage in the Swiss Alps was traditionally a winter trade practiced by farmers who were occupied with outdoor work from spring to fall. When Kohler was 2 2 , having practiced alpine farming and cheesemaking with his father, he paid an old cooper fifty Swiss francs for four months of winter training. At the time (1923) the wage for a day’s work was three francs. The next winter Kohler returned for another session. This time his usefulness earned back the fifty francs, and he was presented with a set of coopers’ tools, which he still uses. Kohler says that when he got into cooperage the craft was in its decline. New factory-made metal containers were cheaper than coopers’ woodenware, and modern health regulations gradually prohibited using old dairy vessels except high in the Alps. World War II was a good time for coopers, because metal was scarce. But after the war cheap plastics were introduced, and cooperage almost died our. During the last 15 years, interest in traditional crafts has renewed the demand for woodenware. In 1967 Kohler retired from farming and cheesemaking to become a full-time cooper. He still makes a few coopered vessels for farm use, but the greater part of his output goes to the tourist trade: milk buckets, bowls and butter churns that will never be put to work.

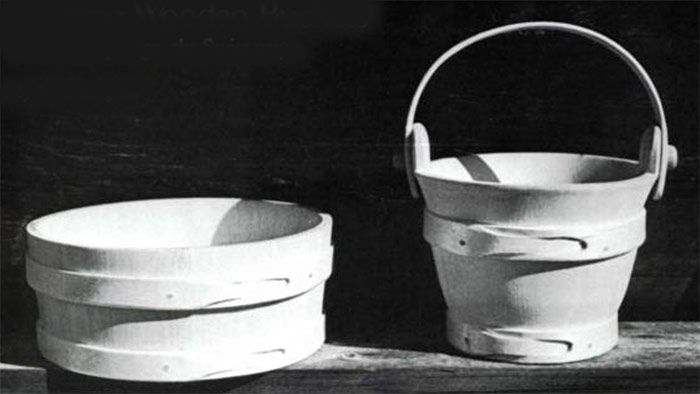

Cooperage techniques are closely related to those of many other traditional woodcrafts. Most of the work is done at a shaving horse, although a workbench with a vise and bench dogs is also useful. Many cooperage tools are shared by other crafts-hewing hatchets, froes, carving knives, drawknives, spokeshaves, planes, saws, drills, etc. Coopers also use several specialized tools-curved (hollowing) drawknives, convex-soled planes, and a device called a croze, which cuts a groove for the bottom board inside the assembled staves. I’ll discuss each as it comes to hand when making a typical, single-bottom, staved container, 220mm (8 5/8 in.) in diameter and 120mm (4 3/4 in.) high.

From Fine Woodworking #40

From Fine Woodworking #40

To view the entire article, please click the View PDF button below:

Log in or create an account to post a comment.

Sign up Log in