Synopsis: Carlyle Lynch built a modestly proportioned Queen Anne cherry highboy to test his adaptations from a mahogany original. He thoroughly explains how to make one just like it, and starts by telling how to square the pieces for the legs using a lathe, tablesaw, bandsaw, and hand tools. When making the lower case, wait to scroll-cut the apron until a gentle fit of its tenons poses no danger of breaking it. Grooves and buttons hold the top onto the upper case, and all the drawers are made alike. The article includes several sets of detailed drawings and a thorough bill of materials.

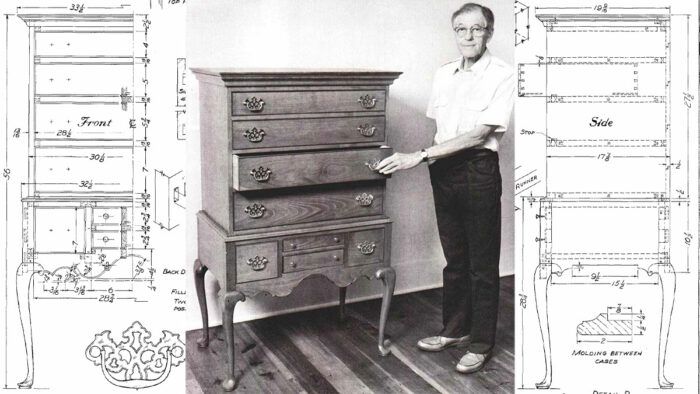

The highboy is an imposing furniture form, too large for the spaces in which most of us live. But 18th-century cabinetmakers didn’t always build grandly scaled furniture for stately halls. Shown here is a small, modestly proportioned highboy I found in the home of Mr. and Mrs. Richard P. Lewis in Augusta County, Va. Included in the drawings are a few adaptations—simpler moldings and a less arched front apron that accommodates one more drawer than the original. I built the piece to test these alterations. Here are the basic procedures.

The legs— Begin by squaring the pieces for the legs. The article that follows on p. 36 gives a method for shaping cabriole legs with a bandsaw and hand tools. Here’s how the lathe can be used, in addition to the tablesaw, bandsaw and hand tools, to shape the foot and ankle of these cabriole legs: Make a pattern from the drawing on the facing page, and lay out the leg on the two inside faces, so that the apron, sides and back will all fit flush with the post block. Cut the mortises in the post blocks while the leg blanks are still square.

To shape the legs, first draw diagonals on the leg ends to mark their centers, and punch a mark on each end 1 1/16 in. off-center, as shown in the drawing below. Mount each blank in the lathe on its true centers, with the foot end at the tailstock, and turn the foot. Shape it to the top of the pad, but don’t finish turning the pad yet, or you will lose the offset center you need to turn the ankles. Remount the blank on the two opposing offset centers and turn the ankles. To someone not used to making cabriole legs, the setup looks forbidding. Use slow speed, and take light cuts with a sharp gouge or round-nose chisel held tight and fed slow. You can turn and sand 2 in. to 3 in. of the ankle, and sand to the top of the foot, before remounting the blank on its true centers to turn and sand the pads.

Take the blanks to the tablesaw, and with a smooth-cutting blade set for maximum height, cut the waste to form the post blocks. Set up a stop block to prevent going too far. In order to keep the post block flat on the table, cut two of the legs with the rip fence to the right of the blade, two with the fence to the left of it. Finish the cuts on the bandsaw and then rough out the rest of the leg. Bandsaw to the pattern line on one face, tape the scraps back in place, turn the leg 90° and saw again to the lines on the scraps. Final shaping is done with spokeshave, rasp and scraper.

From Fine Woodworking #42

From Fine Woodworking #42

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Bessey EKH Trigger Clamps

Stanley Powerlock 16-ft. tape measure

Circle Guide

Log in or create an account to post a comment.

Sign up Log in