Synopsis: Using a bandsaw to cut the pins and tails results in something pretty similar to handcut dovetails, says Tage Frid. In this quick article, he offers pointers and step-by-step instructions on how to cut them this way yourself. Cut the pins first, and then tilt the bandsaw table 10 degrees. Clamp a fence parallel to the blade. Drawings show how to adjust the fence to the width of your stock.

Routers and tablesaws aren’t the only way to make through dovetails with a machine. I use my bandsaw to cut the pins and tails, and the results aren’t much different from cutting the joint by hand. Start by using a marking gauge to scribe the baselines of pins and tails on both boards. Cut the pins first. Tilt the bandsaw table 10° (or whatever angle you wish your pins to be) to the right, and clamp a fence parallel to the blade and slightly farther away from it than half the width of the stock, as in drawing A. (If your table won’t tilt in both directions, see FWW #17, p. 15, for a jig to solve this problem.) Clamp a stop to the fence so that the blade will cut just to the baseline. All the cuts for this method should be made with the inside face of the board up. Mark your stock so that you won’t lose track. Make the first cut, which will be one side of a center pin, then turn the stock end-forend and make the second cut, one side of the other center pin.

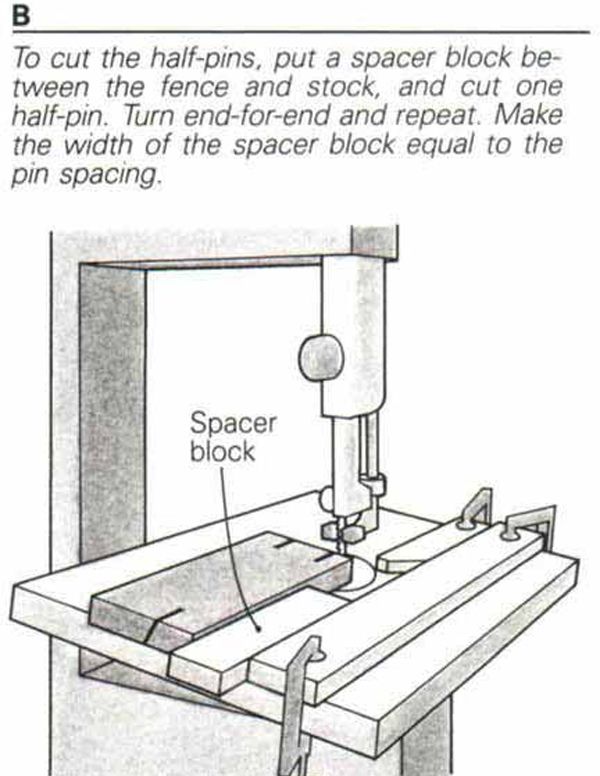

Between the stock and the fence, place a spacer equal in width to the pin spacing. For this example, you’ll cut one center pin and two half-pins at each edge. Cut the half-pin on one end of the stock, then turn the board end-for-end and cut the other half-pin (B).

Now tilt the table 10° to the left, move the fence to the opposite side of the table, and use the spacer to cut the other two half-pins (C). Then remove the spacer and cut the other side of the two center pins (D). Chisel out the waste in the pin boards, just as you would in making hand dovetails.

With the pins chiseled out, scribe their location directly on the tail board (E). Return the bandsaw to the horizontal position and saw freehand to the waste side of the lines that mark the tails.

From Fine Woodworking #43

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Stanley Powerlock 16-ft. tape measure

Starrett 12-in. combination square

Log in or create an account to post a comment.

Sign up Log in