Synopsis: Sam Bush, Larry Brusso, and Simon Watts share tips on installing hinges. Bush explains how to install them on jewelry boxes; one of his tips is to mark screw holes a tiny bit off-center to the inside to draw the hinge leaf in tight. Brusso talks about using a gauge to speed knife-hinge installation, which he uses on cabinet doors. He also explains how to mark L-shaped hinges. Watts discusses how to install a lock into a chest with a lid of frame and panel, plywood, or veneer construction, to avoid seasonal movement difficulties. All the explanations are accompanied by detailed drawings to illustrate their techniques.

Mounting hinges on a small box can be at the end of the project, when you’d like to be done. Here are a few ideas I find helpful for hinging a box of the card-file type, where lid and box must align well.

I prefer using unswaged brass butt hinges because they’re attractive and readily available. It’s handy if the hinge-leaf width is the same as the box-side thickness, since this avoids having a closed mortise with a fragile back wall. Two hinges are enough for boxes up to 12 in. long; for longer boxes, I might use three.

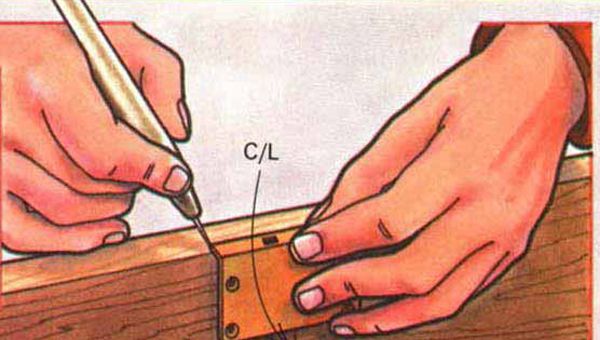

For high-quality work, mortise the hinge leaves into both the box and the lid. A little off the pace but still okay is to mortise the entire hinge into only the box, screwing the top leaf right to the lid so it stands proud of the surface. Either way, clamp the lid to the box as shown in the drawing so the ends accurately line up, and lay out the hinges by eye, adjusting so they’re equidistant from the ends. Now mark the length of the mortises with a knife drawn against the ends of the hinges or by just nicking and then using a square.

If the mortises are to be cut with chisels, lay out the depth and width with the marking gauge set as shown. Depth lines should be inside and out if the mortise is open. Chisel cautiously, with the tool’s bevel facing up so that the chisel’s flat back will leave a flat mortise. Be careful not to go too deep, or you’ll end up with bound hinges that spring the lid open at the front.

I prefer to cut the mortises with a mortise bit in a router and clean them up with a chisel. I set the router for depth and its fence for width right from the hinge, then test it on a scrap. If I’m making a double mortise, I cut the scrap in half and close it over the barrel of the hinge to test the depth. Single or double, it’s the barrel, not the leaf thickness, that governs depth. I make the mortise a touch shallow, which leaves a tiny gap at the back of the box but ensures that the front will close nicely.

From Fine Woodworking #49

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Stanley Powerlock 16-ft. tape measure

Starrett 12-in. combination square

Dubuque Clamp Works Bar Clamps - 4 pack

Log in or create an account to post a comment.

Sign up Log in