Synopsis: David Sloan used to bluff his way through lumberyards, until it cost him time and money. In this article, he shares what he’s learned in books and through three-day log-, lumber-, and tree-grading workshops. Grades provide the basis for determining lumber quality and price, and Sloan explains standard grades, abbreviations, nonstandard grades, and how grading works. Side information follows a lumber grader in action.

I’ve bluffed my way through many a lumberyard. I learned young. When I was a kid, I wanted a big hunk of maple to make a rifle stock. At the lumberyard, the man in charge pointed to a pile of thick maple planks. “Come and get me when you’ve found what you want,” he said. I did, and for years afterward, that’s the way I bought wood. Whenever I’d hear lumberyard lingo like “FAS or number one common, sir?”, I’d put on my poker face, give a knowing nod, and say, “Sure. Uh, do you mind if I look through the boards?” I didn’t have the slightest idea what lumber grades like FAS or No. 1 common meant, but I knew a nice board when I saw one.

My bluff worked fine until I bought wood for a big job. I didn’t have time to pick through a hundred oak boards, so I went with a grade called No. 2 common because it was cheap. Much to my dismay, there was a short, narrow, knotty board for every nice one that came off the truck. I suggested that the knots added character, but my customer didn’t agree. I had to order more oak, and ultimately lost money on the job.

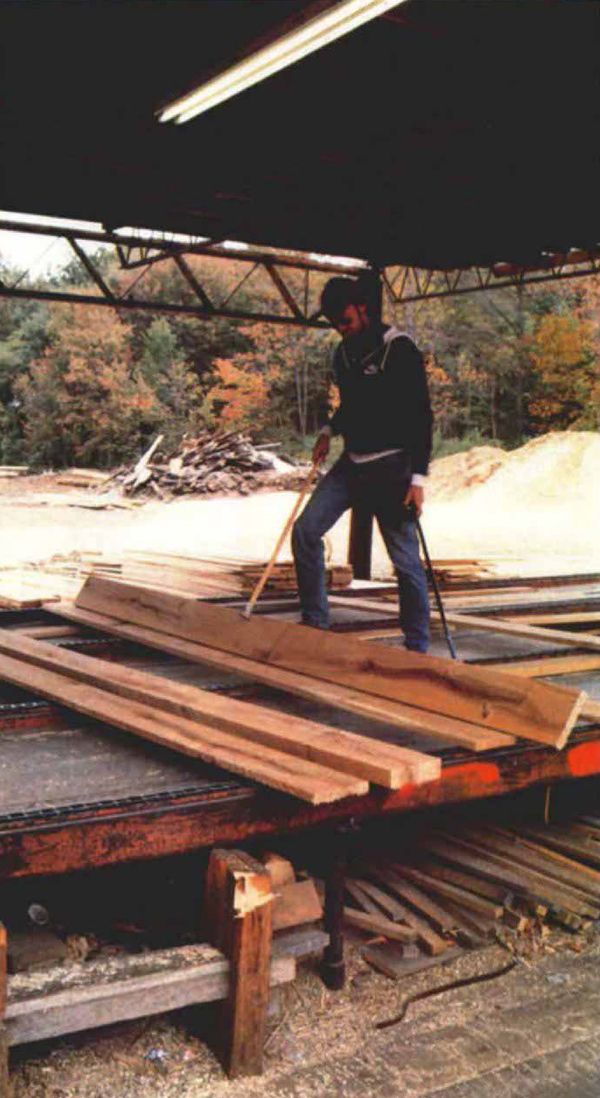

That lesson motivated me to learn about lumber grades. I picked up the basics from books. Recently I rounded out my education by attending a three-day log-, lumber- and tree-grading workshop in Indiana, where I even got to do a little grading myself. Purdue University and the Indiana Hardwood Lumberman’s Association sponsor several of these workshops each year. Attending one is a good way to learn about hardwood grading. (For information, write to Daniel Cassens, Dept. of Forestry and Natural Resources, Purdue University, West Lafayette, Ind. 47907.)

Grades provide the basis for determining lumber quality and price. The concept of hardwood grading is simple: a highgrade board must have more clear, defect-free surface area than a low-grade board. The grading system provides standards for defects and board size, and equations for calculating clear surface area.

From Fine Woodworking #50

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Starrett 12-in. combination square

Estwing Dead-Blow Mallet

Log in or create an account to post a comment.

Sign up Log in