Starting Out: Simple Bookcase Joints

The third of four articles to help beginning woodworkers get going with the craft

Synopsis: In this third of four articles on starting out, Roger Holmes explores the varieties of bookshelf joints. Box joinery can be as complex or simple as your skill and patience permit; he explains how to make a tongue-and-groove bookshelf that’s strong and easy to assemble. He recommends dadoing by hand and explains how to plow the grooves in the joints. Side information details how to do the same work with machines, instead of hand tools.

I can’t remember the last time I rented a house with bookshelves (or enough closets for that matter, but I own a lot more books than shirts). So for years I’ve lived with makeshift shelves—planks on bricks and brackets, planks wedged into alcoves. Confronted with another shelfless house recently, I finally decided to make some permanent shelves that could move with me from house to house. The result, a stack of two simple boxes, one shallow, one deep, is shown in the drawing at right.

Boxes—called carcases in traditional parlance—are the cabinetmaker’s basic building blocks. Stripped down to essentials, most casework isn’t much more than a box-like container, usually filled with boxy drawers. In fact, most of the furniture in my house is made of simple rectangular boxes. For example, scale down the shallow box shown on top in the drawing for a spice rack or knickknack shelves; add a mirrored door and you’ve got a medicine cabinet. Slide a stack of smaller boxes into the deep bottom box and you’ve got a chest of drawers (I’ll show how to do this in a subsequent article).

I made my boxes of pine, tailoring the depth of the upper box to the width of the boards I had on hand. I started with 10-in. wide boards for that box, but tapered the sides to add a little stability and to break the monotony of all those rectangles. The wider sides, top and bottom of the lower box had to be edge-joined and glued up.

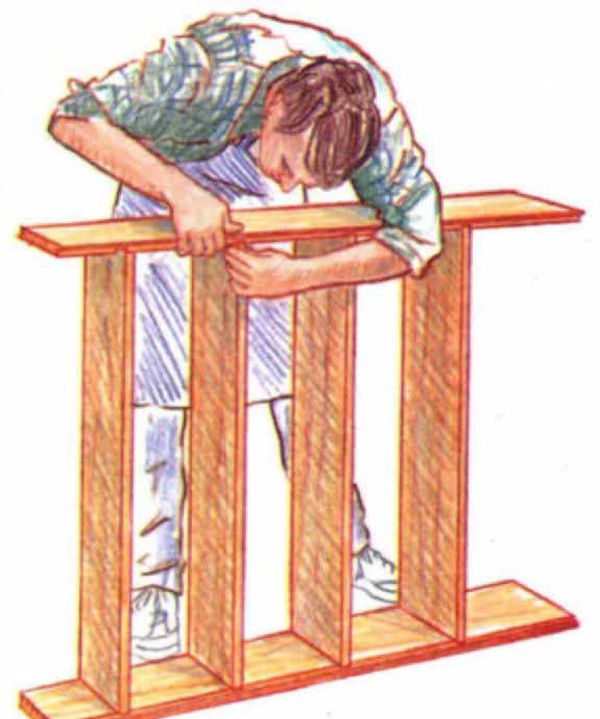

Box joinery can be as simple or as complex as your skill and patience permit. Anybody can nail a butt joint together, and for some things that’s joint enough. Secret mitered dovetails are at the other end of the scale, and I don’t know many people who use them regularly. For my bookshelves, I wanted more strength than a simple nailed butt joint would give, but I didn’t want to spend a lot of time getting it. The upper box, therefore, was put together entirely with dadoes—strong, easily cut joints in which the full thickness of each shelf end is housed in a groove in the side. (If you want adjustable shelves, just dado the top and bottom shelves and support the others on dowels as shown for the adjustable shelf in the lower box.)

From Fine Woodworking #50

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Festool DF 500 Q-Set Domino Joiner

Festool Rotex FEQ-Plus Random Orbital Sander

Ridgid EB4424 Oscillating Spindle/Belt Sander

Log in or create an account to post a comment.

Sign up Log in