Protecting Wood from Humidity

Lab tests show which finishes work, which don't

Synopsis: William Feist and Gary Peterson of Forest Products Laboratory tested 91 finishes for moisture resistance and concluded that even the best moisture-resisting finishes only slow, but don’t completely stop, the exchange of moisture vapor. They explain how, when, and where wood shrinks and swells, and talk about their tests of all types of finishes. Finishes like linseed oil, tung oil, and furniture polishes are at the bottom of their scale; they let virtually all moisture in. Fillers help plug wood pores and indirectly contribute to moisture resistance, and the authors describe the effectiveness of multiple coats of finish. A chart shows the effectiveness of 20 different finishes they tested. Side information lists sources for some of the unusual or hard-to-find products tested.

Whether indoors and protected from weather, or outdoors and exposed to the elements, wood is always affected by moisture. It swells when it adsorbs liquid from rain, dew or moisture vapor in the air and shrinks as it dries.

Protecting wood from moisture is of no small importance. The more moisture that gets beyond the finish, the more grief you’ll have with warped panels, joints that swell and break, drawers that stick and wood that discolors. Of course, the woodworker’s dream finish would seal the wood entirely against moisture and protect the surface against dirt and abrasion, all without obscuring the appeal of the grain that makes us appreciate wood in the first place.

About a year and a half ago, the Forest Products Laboratory (FPL) completed a study that examined just how well finishes resist moisture vapor. And, while we didn’t necessarily find that ideal finish, we did learn that wood coated with some types of finishes will be less affected than wood left completely unfinished. Our tests of 91 finishes showed that no coating entirely prevents wood from adsorbing moisture. We also found great differences in the effectiveness of many finishes. Some popular ones (linseed oil, tung oil and lacquer, for example) represent hardly any barrier to moisture vapor while other materials that aren’t even considered to be finishes—paraffin wax, for instance—sealed the wood almost completely.

The problem with protecting wood from moisture vapor lies in the material itself: it’s literally full of holes. In fact, when seen under magnification, it would not be inaccurate to describe wood as mostly pores surrounded by smaller amounts of organic material. These pores provide lots of entry points for moisture vapor; and even the finish meant to seal them will be somewhat permeable. Ultimately, even the best moisture resisting finishes only slow, but don’t completely stop, the exchange of moisture vapor.

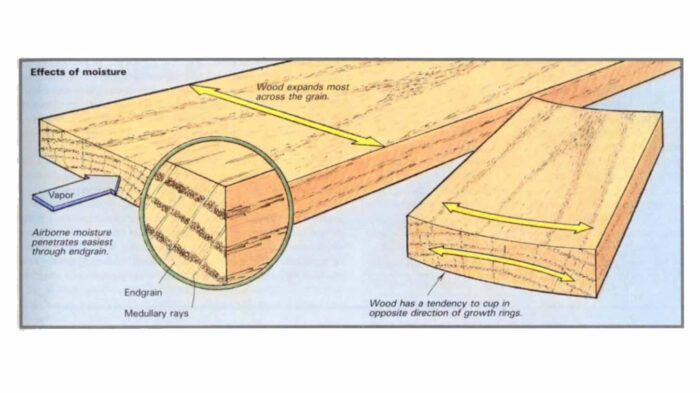

As wood takes on moisture vapor, it expands—which explains why a door that closes just so in the winter sticks annoyingly when humid summer weather arrives. As the drawing above shows, most of the expansion (and when the wood dries, contraction) occurs across a board’s width rather than along its length. More shrinking and swelling will take place parallel to the growth rings than perpendicular to them. Thus, a board sawn so its growth rings are parallel to its face (plainsawn) will shrink and swell much more than a board sawn with rings perpendicular to its face (quartersawn).

This bit of wood lore is useful to know for two reasons. First of all, a quartersawn board will be less likely to warp because it expands less across its face. Secondly, to reduce warpage in any wood, moisture exchange must occur evenly on all sides and edges of the board. So, if you coat only one side with a finish, the face you skip will pick up or lose moisture faster than the coated side.

From Fine Woodworking #64

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Ridgid R4331 Planer

Sawstop Miter Gauge

Starrett 12-in. combination square

Comments

Something is off with the PDF on the 3rd page. Almost like 1/3 the text is missing... very hard to understand.

Log in or create an account to post a comment.

Sign up Log in