Synopsis: Because of the way wood moves, any furniture construction that restricts wood movement by fastening one piece of wood cross-grain to another courts problems. Ways have evolved to allow cross-grain movement while using traditional design elements. Jim Cummins offers a few ideas and embellishments from Tom Hagood, Walter Owens, Norman Vandal, and Warren May. Hagood’s idea is a crown-molding dovetail; Owens’ routs full-width sliding dovetails to fasten drawer frames into carcases. Vandal routs a T-shaped slot along a drawer glide, and May has a way to hold small applied moldings to case parts.

Wood swells and shrinks in width and thickness as it absorbs and loses water according to the changing relative humidity of the air around it. But humidity hardly affects length at all. Therefore, any furniture construction that restricts wood movement by fastening one piece of wood cross-grain to another courts problems. Many old pieces built this way have cracked or warped because they couldn’t withstand the drastic moisture changes caused by central heating. Contemporary builders can avoid cross-grain problems by using plywood and particleboard. Because of their balanced internal structure, both are very stable and may be glued “cross-grain” with impunity. Yet plywood and particleboard are not the most pleasant materials to work with, and they result in a contemporary look that’s not always what a woodworker wants.

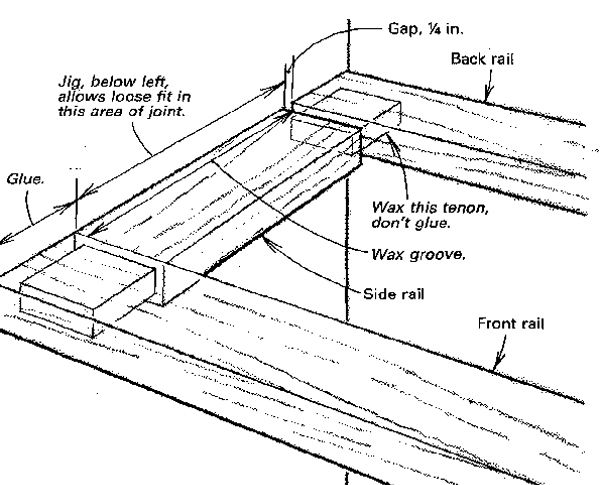

Modern solid-wood furniture usually leans toward the old designs and the old construction methods, making it prone to all the old problems. Yet ways have evolved to allow cross-grain movement while still using traditional design elements such as drawer runners and applied moldings. Typically, one piece is allowed to slip along the unmoving long-grain piece by means of sliding dovetails, screws fastened through slots rather than tight holes, or other devices (such as the buttons that hold tabletops to aprons) that allow movement without compromising strength.

Many of these solutions are very familiar because they have appeared in construction drawings for project after project. Here are a few less obvious ideas and embellishments that have recently come to our attention:

Tom Hagood of Birmingham, Ala., came up with a way to attach crown moldings, as shown in drawing A. The advantages are that it’s relatively easy to make the joint using a router and dovetail bit, the applied dovetail piece replaces the screws-in-slots that would otherwise be visible inside the case and the molding may be easily removed if the piece has to be moved through doorways. Crown moldings typically leave a gap at the top between the molding and the case. This may be filled in with another strip of wood, but the usual treatment is to apply a solid top, with molded edges, that overhangs on front and sides, complementing the molding profile.

From Fine Woodworking #72

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Starrett 12-in. combination square

Pfiel Chip Carving Knife

Veritas Precision Square

Log in or create an account to post a comment.

Sign up Log in