Surfacing Stock with a Router

How a simple fixture can true up wide boards

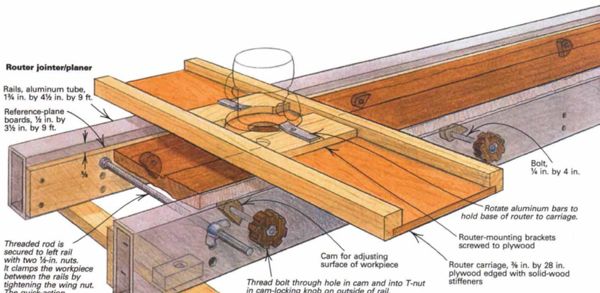

Synopsis: Tim Hanson built a router/planer that holds boards without clamping out twists or bends, while showing him where the plane is in relation to the board. It’s made of two aluminum rails with reference-plane boards screwed to their inside faces, and six cams with locking knobs for aligning the workpiece’s top surface with the reference plane boards. He used all-thread rod to clamp the rails to the workpiece and a carriage for his router. He explains how to build the fixture and how to surface stock and joint edges with it. A project drawing shows how the fixture is made.

Did you ever get a good deal on a load of lumber, only to notice while unloading it at home that the rough boards were all twisted, bowed or cupped? Then, as the stack of 8- and 12-in.-wide boards began to dwarf your narrow jointer, and it became clear that it would take forever to process the lumber, did the flush of a great deal give way to disappointment? I know the feeling. I put off using 500 bd. ft. of roughsawn walnut for more than two years because of the limitations of my 5-in.-wide combination jointer/planer.

Finally, I decided to set up a router to flatten the boards. I mounted my router on a bridge that would slide on my workbench while straddling one of the rough boards clamped to the bench. Oh, I got a smooth face, but when I removed the clamps, the bow and twist were still there. I needed to hold the board without clamping out its twists or bends, then pass the router over the board in a straight, flat plane—and I needed to know where that plane was in relation to the board. The router jointer/planer in the drawing above solved these problems better than I hoped. It consists of two aluminum rails with “reference-plane” boards screwed to their inside faces, six cams with locking knobs for aligning the workpiece’s top surface with the reference plane boards, some all-thread rod to clamp the rails to the workpiece and a carriage for my -HP Black & Decker router. For “planing” with the router, I use a -in.- dia. carbide mortising bit with a -in.-dia. shank made by W.K.W Wisconsin. The bit is available from Edwin B. Mueller Co. Inc., 3940 S. Keystone Ave., Indianapolis, Ind. 46277; (317) 783-2040.

How to surface stock—The two 9-ft. rails are the backbone of the rig. They provide a flat and true plane for the router carriage to slide on. The rough or twisted workpiece is supported between the rails on the adjustable wood cams. By adjusting the cams, you can raise or lower one end, or even one corner of the workpiece until its entire top surface is level with or higher than the reference-plane boards. The reference-plane boards are also used to set the depth of the router bit, therefore defining the plane in which the cutter will pass over the surface of the workpiece. After the top surface of the workpiece is set, the rails are “clamped” to the edges of the workpiece with an all-thread rod at each end of the rails. Then the carriage-mounted router is switched on and slid along the rails, “planing” the board fiat.

The cutting passes are made in a continuous motion and at a moderate speed along the grain of the wood from one end of the board to the other.

From Fine Woodworking #77

For the full article, download the PDF below:

Fine Woodworking Recommended Products

MicroJig Matchfit dovetail clamps

Incra Miter 1000HD

Log in or create an account to post a comment.

Sign up Log in