Using a Portable Belt Sander

An abrasive approach to flat surfaces and smooth curves

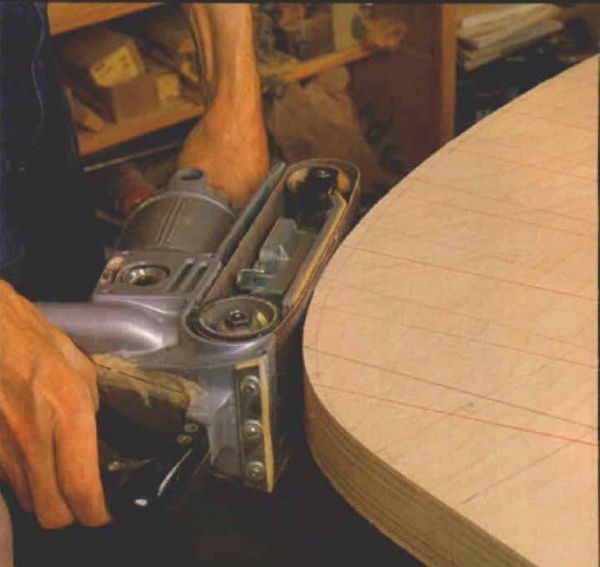

Synopsis: Chris Becksvoort says the portable belt sander is a workhorse in his shop. He uses it to grind down humps and bumps, level large surfaces, and smooth even highly figured woods like bird’s-eye maple. Here, he explains how to handle the most common sanding problems and get good performance from the machine. He starts with the sander’s anatomy, shares tips on how to use the tool effectively, and talks about how to smooth panels, level surfaces, and work up to sanding edges and frames.

The portable belt sander is a real workhorse in my shop. It grinds down humps and bumps, levels large surfaces in a fraction of the time it would take to plane and scrape them, and it smooths even highly figured woods like bird’s-eye maple. It’s a versatile tool for everything from removing paint to shaping cabriole legs. But a belt sander can also be a recalcitrant tool and difficult to live with. At its worst, it refuses to track correctly, and it gouges the wood, sputters and coughs while spewing clouds of fine dust. Over the years, I’ve come to terms with the tool and in this article, I’ll show you how to handle the most common sanding problems and get good performance from your machine.

Belt-sander anatomy—All portable belt sanders work pretty much in the same way. The sander’s motor powers the rear drive roller through a gear reduction drive. Most sanders are belt driven, but the better, heavy-duty sanders are chain driven. The front roller, which rotates freely, is spring-loaded to tension the sanding belt. A lever releases the tension whenever the belt must be installed or removed. Turning an adjustment knob swivels the curved front roller slightly and coaxes the belt to track correctly and ride dead center on the rollers. A rigid platen between the two rollers provides a flat sanding area. The belt itself is backed by a replaceable steel wear plate that rests on a cork cushion that is attached to the platen. Sacrificial steel or ceramic strike bars prevent the edge of the rotating belt from damaging the sander’s housing.

Using the belt sander—A belt sander is a relatively safe machine, but there are a few common-sense precautions that you should observe while operating one. Belt sanders typically weigh from 8 lbs. to 15 lbs. and most require two hands to operate safely. Although a dust bag is a valuable accessory, it won’t pick up all of the dust, so wearing a mask is a must. Always wear safety glasses. Most belt sanders are noisy and high pitched; if you expect a lengthy session, it’s also a good idea to use ear protection.

Before beginning to sand, unplug the machine and clean the dust intake chute of any clogged dust and chips. Then, make sure the belt is installed properly.

From Fine Woodworking #78

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Festool Rotex FEQ-Plus Random Orbital Sander

Bosch 12V Trim Router

Festool DF 500 Q-Set Domino Joiner

Log in or create an account to post a comment.

Sign up Log in