Sharpening Twist Drills

Grinding standard and brad-point bits freehand

Synopsis: Even the most dedicated woodworker can spend a lifetime perfecting his or her tool-sharpening skills. Shaping standard twist bits is simple and fast, says Ken Donnell, who explains here how to do that and convert twist bits to brad-point drills on a bench grinder. You’ll learn the basics of how twist drills work, the four criteria for sharp, efficient twist drills, and the steps involved in converting them. He shows how to test them for accuracy with a gauge or a try square.

My first lesson in woodworking came from my former scoutmaster, Merle Schelase. I’ve often visited his workshop and always received the same lesson: how to sharpen a scraper, handsaw, chisel ancl drill bit. Each visit, he showed me these same, seemingly simple procedures and I always learned new and useful information. Most of all, I learned that even the most dedicated woodworkers can spend a lifetime perfecting their tool-sharpening skills.

While most woodworkers wouldn’t think of using a poorly sharpened knife or chisel, few pay equal attention to their drill bits. But a sharp bit is as valuable as a sharp paring chisel. Shaping standard twist bits is a fast and simple procedure. It’s equally easy to convert twist bits to even more efficient brad-point drills by shaping them freehand on a bench grinder.

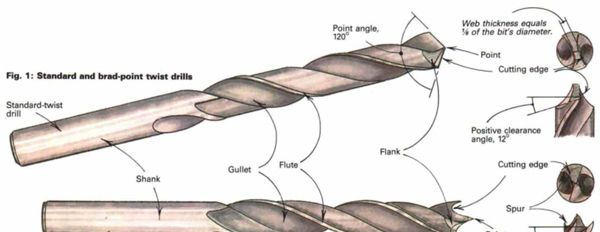

Both standard and brad-point twist drills, such as those in figure 1 above, are intended for high-speed drilling in portable electric drills or drill presses. Each bit has a center point, two cutting edges, continuous flutes that align the bit in the hole, and gullets between the flutes through which chips are cleared from the hole when drilling.

To understand the difference between standard and brad-point twist drills, let’s look at how each bores a hole in wood. On any bit, the cutting edges pare with, across and against the grain as the bit is turned. On a standard bit, the outer corner of this edge cuts the hole’s circumference and commonly tears the wood fibers when going against the grain, leaving a ragged edge and an oval hole. On the brad-point bit, the spurs score the circumference of the hole, eliminating fraying, and cut the hole round. The bradpoint drill cuts wood more efficiently than a standard bit because its cutting angle is smaller and because its spurs shear the wood and create a smooth exit hole. And since a standard-drill-bit point is blunt, compared to a brad-point drill, it “walks” on the surface unless you punch the hole’s center. Brad-point drills, because of their long, thin point, start and center easily.

My principal twist drill sharpening tools are a standard bench grinder, with a in.- to l-in.-lhick by 6-in.-dia., 60-grit Carborundum wheel, and two simple test gauges. A hand-held die grinder, such as a Dremel tool, a small cylindrical stone and a woodcarver’s slip stone are useful, but not essential. Always wear safety glasses when using either the hand-held or bench grinder, and grind only on the front, outer circumference and corners of the wheel, not the side. Grinding on the side can wear the wheel, eventually causing disintegration and possible injury.

From Fine Woodworking #82

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Fein Turbo II HEPA Wet/Dry Dust Extractor

Mist Coolant System

Stanley Powerlock 16-ft. tape measure

Log in or create an account to post a comment.

Sign up Log in