Building a Gate-Leg Card Table

Tackling curved rails and inlaid legs

Synopsis: Frank M. Pittman researched designs for 10 years before building this gorgeous gate-leg card table. It has tapered legs and string inlay similar to Hepplewhite pieces. Pittman says the first thing is to make full-scale drawings of the table, because of the inlays and curved aprons. He explains how to make the legs, banding, and stringing, the inlays, and how to veneer the front and side aprons. The rear apron is made of three parts, which he details before talking about gluing up the base and attaching the top. He closes with tips on mounting the hinges and achieving a satin sheen. Detailed project plans illustrate the design.

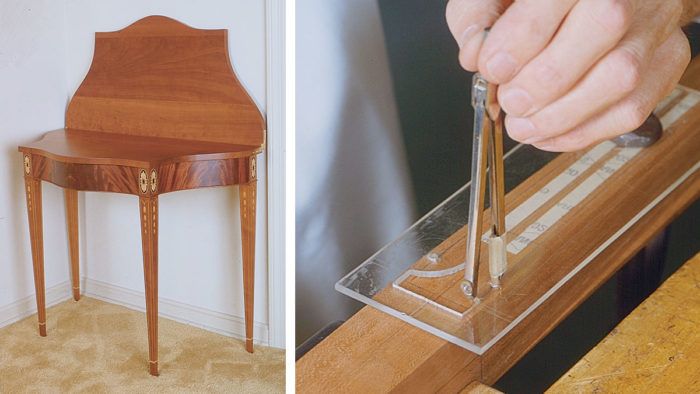

About 10 years ago I promised my wife I would build her a card table. Needless to say, after a decade of watching me “research” the problem, she had almost given up hope, and so she was especially delighted when I presented the gate-leg card table shown at left.

Tables such as these, with tapered legs and string inlay, are often attributed to the 18th-century furniture designer George Hepplewhite, but my research suggests that this association may not be entirely accurate. Hepplewhite’s principle claim to fame is a book of furniture designs, The Cabinet-Maker and Upholsterer’s Guide, published by his wife Alice in 1788, two years after his death. And although the tables illustrated in this book have the same light proportions and similarly tapered legs, none have the same balance of uncluttered lines and graceful curves that enhance the table shown here. Fortunately, I can avoid attributing the table’s design to a particular style by crediting a former teacher of mine, Walter B. Nalbach, with its inspiration. Nalbach built a pair of tables similar to this in the 1930s, and with his permission I measured them and incorporated a few minor design changes of my own, such as running the string inlay on all four faces of each leg and inlaying the bell flowers on two faces of each leg instead of just one.

My table is from cherry, with crotch mahogany veneer on the aprons. The legs require 6 bd. ft. of stock, which is enough for the table’s four legs plus one extra for checking the tool setups for the many machining operations involved with the inlays. The top requires 11 bd. ft. of well-matched stock. You’ll also need an additional 2 bd. ft. of cherry for the back apron, which is actually a three-part construction that includes an inner apron dovetailed into the side aprons and the two-part knuckle-joint gate-leg mechanism that supports the hinged top when open. The cherry apron beads can be made from leg or top scraps. The front and side aprons are stack-laminated poplar, bandsawn to shape and then veneered. I used about 10 bd. ft. of -in.-thick poplar for the laminated blanks.

Because of the curved aprons and the intricacies of the inlays, the first step in building this table is to make full-scale drawings to work out the details in actual size. You’ll need patterns for the curved parts anyway, and so you might as well prepare them ahead of time.

From Fine Woodworking #86

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Whiteside 9500 Solid Brass Router Inlay Router Bit Set

Bahco 6-Inch Card Scraper

Comments

Very nice table, Frank, thank you! I'm stealing ideas for another piece I'm building, a desk, not a table.

Log in or create an account to post a comment.

Sign up Log in