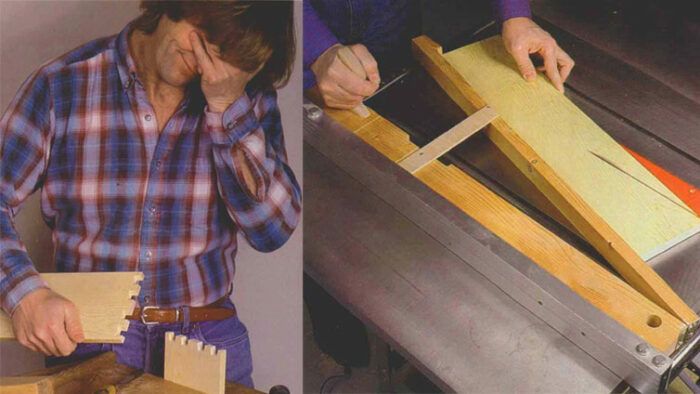

Dealing with Woodworking Mistakes

To err is human, but clever repairs are divine

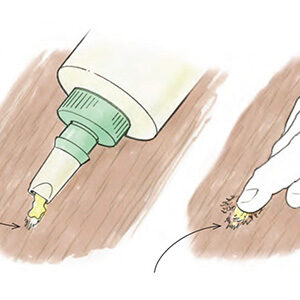

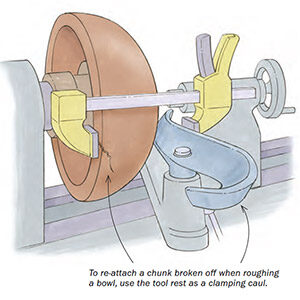

Synopsis: Because the universe of possible foul-ups is limitless, it’s as important to learn to deal with mistakes as it is to learn to sharpen a chisel or adjust a tablesaw. Finding the right remedy is the challenge. In this article, Fine Woodworking’s Sandor Nagyszalanczy collects methods for dealing with common woodworking mistakes. More than a dozen professional woodworkers’ strategies are detailed, including how to deal with short cuts, repairing and covering up defects, tightening loose fits, warped panels and parts, assembly and finishing failures, and how to remember your mistakes so you learn from them. Side information talks about avoiding mistakes by using good design and careful measuring, along with tips for cutting and machining parts, assembly and glue-up, finishing, and time management.

There was scarcely a whisper in the room as we watched Japanese temple carpenter Makoto Imai demonstrate how to mark out a scarf joint that seemed to have the complexity of a Rubic’s cube. The silence was broken by one Santa Cruz Woodworking Association member who had paid to see the traditionally trained craftsman perform: “Since all your layout work is in ink, how do you erase a mark if you make a mistake?” Brushing back his jet-black ponytail, Imai replied simply, “Don’t make a mistake.”

But all woodworkers occasionally make mistakes. We make them for various reasons: bad luck, lack of skill, not approaching the task logically enough, fatigue or distractions. Little foul-ups, like sawing a part too short, are inconvenient at best and can disrupt work flow. More serious errors, like ruining a pair of book-matched panels, can take the wind out of our sails and make woodworking tedious instead of fun. For professionals, blunders and slipups can lead to overtime and drain the profit from the job. Because the universe of possible foul-ups is limitless, it’s just as important to learn to deal with mistakes as it is to learn to sharpen a chisel or adjust a tablesaw. As Japanese craftsman Toshio Odate says, “Accept human error, but be prepared for it so it doesn’t inconvenience you.”

To repair or to remake

After the drained feeling that comes from having erred has passed, you must ask yourself a question that renowned cabinetmaker and teacher James Krenov told me is at the heart of what to do next: “Can I correct the mistake in a way that I feel good about and that won’t interfere with my or the viewer’s enjoyment of the finished piece?” A negative response might mean that you’ll sleep better if you remake the part. But if you’re up to the challenge, it’s time to find the right remedy for the error—a task that can take as much cleverness as designing your project in the first place.

I’ve assembled a collection of methods for dealing with some of the most common mistakes woodworkers are likely to face. In addition to my own ideas, I’ve picked the brains of more than a dozen professional woodworkers. Some of these error antidotes are from the repairman’s bag of tricks; others are the inventions of desperate men trying to save their assets in a pinch.

From Fine Woodworking #95

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Diablo ‘SandNet’ Sanding Discs

Starrett 12-in. combination square

Log in or create an account to post a comment.

Sign up Log in