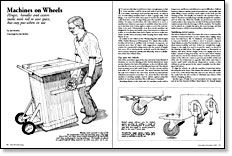

Machines on Wheels

Hinges, handles and casters make tools roll to save space, but stay put when in use

Synopsis: Readers wrote in with suggestions on how to stabilize tools on wheels; this article distills the best of those ideas. They include attaching two lawnmower wheels to the back of a tablesaw; using stabilizing swivel casters; hinged dollies; and low-tech ideas for wedging or propping wheels. Drawings illustrate everyone’s suggestions.

Every woodworker would love to have enough space so that every machine could be set up and ready to go at all times. In reality, most shops don’t provide that luxury. As often as not, woodworking machines have to share a garage with, of all things, a car. And even if the shop space is sacred unto itself, tool collections have a way of outgrowing space the way kids outgrow clothes. For many woodworkers, the only solution is to move a machine into whatever open space is available when they need to use it and then stow it away again to make room for the next machine to be used. Unfortunately, most floor-model machines are designed to be heavy and stable; ease of movement is a minus not a plus, so woodworkers have had to figure out how to make machines mobile when necessary while keeping them stable when they’re in use.

In a letter to the editor in Fine Woodworking #93 (March/April 1992), Charles Klaveness of Hempstead, N.Y., asked other readers for ideas about how to stabilize tools on wheels. In response, we received more than 20 letters with suggestions ranging from sources for commercial locking casters to tried-and-true methods used in the theater to move scenery and props quickly and efficiently. Here is a distillation of the best of these ideas.

Tip onto two wheels

One of the most direct approaches was sent in by Dean Stevick of Herndon, Va. Stevick attached two lawn mower wheels to the back of his tablesaw, so the tool still sits solidly on the floor but can be moved by lifting its front end. The wheels were mounted on an axle made from a -in.-dia concrete anchor bolt with a 90° bend in one end. The metal brackets that hold the axle were bolted to the saw’s base. Stevick recommends the wheels be mounted no more than in. above the floor when the machine is standing upright. And he advises against using this method on top-heavy machines like a drill press or bandsaw.

Mounting wheels on the back side of a machine works well as long as you can lift one end without too much difficulty. J. Rufford Harrison offered a similar method but added two oak handles that make lifting a heavy machine much easier on the back. The handles are bolted to the machine’s base or stand so that they normally hang vertically alongside the machine and out of the way. When the handles are pivoted up to the horizontal position, they bump into another bolt that prevents further rotation and provides the leverage to lift the machine. The handles can be placed at a height that gives the most leverage and that makes it easy to roll the tool around like a wheel barrow.

From Fine Woodworking #97

For the full article, download the PDF below:

Fine Woodworking Recommended Products

WoodRiver Router Bit Storage Case

Woodriver Rechargeable Desiccant Bag

Log in or create an account to post a comment.

Sign up Log in