Mastering the Tablesaw

There's a way to be safe in every cutting situation

Synopsis: Mark Duginske explains the fundamentals of ripping and crosscutting on the tablesaw and offers tips on more complicated maneuvers. He starts with discussing the rip fence, how to rip, how to test for parallelism, and how to saw rabbets. He talks about safe techniques for ripping and various push-stick designs, and using auxiliary fences. He covers crosscutting with the miter gauge. Side information explains how to set up and align your miter gauge and rip fence.

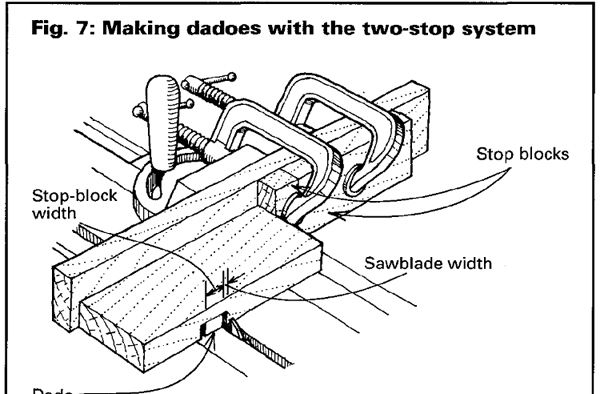

The tablesaw is the heart of most woodworking shops. With a standard blade, you can make virtually any straight cut, and when fitted with a dado head, the tablesaw is the tool of choice for cutting grooves, dadoes and rabbets. When equipped with shopmade jigs, the tablesaw is the most efficient tool for finger joints, tenons and even dovetails.

Although undeniably versatile, the tablesaw also has its dark side. It is probably responsible for more injuries than any other woodworking tool. Many of those injuries could be avoided if woodworkers used blade guards and splitters and if they took the time properly to set up and to align the rip fence and miter gauge. But above all, for safe operation of a tablesaw, you must understand the fundamentals of ripping and crosscutting.

Using the rip fence

The rip fence is a straight edge aligned parallel to the blade that slides along a bar at the front of the saw table. When the fence is locked to the bar, the distance between the blade and the fence determines the width of cut. To rip safely and accurately, the workpiece must lie flat on the table with a straight edge against the rip fence. If the edge is not straight, joint it straight before making the cut or make a jig to hold the wood securely while making a straight cut. One option is to screw or nail a wooden straight edge to the workpiece. If the wood is not flat, face-joint it to establish a flat surface or position the workpiece so that it doesn’t rock during the sawcut. Never rip a badly twisted board because it will bind and may kick back. Sometimes you can salvage a badly twisted piece of wood by cutting it into smaller lengths first.

To ensure that the fence locks parallel to the blade, always adjust the fence toward the blade rather than away from it, and then apply pressure on the front of the fence before it is locked in place. Periodically, check the alignment of the fence to the blade by measuring from the fence to the front of the blade and then to the back of the blade. The distance should be no more than in. greater at the back of the blade. A faster and more accurate way to check whether the blade and fence are parallel is with sliding wedges, as shown in figure 1 below. To accommodate different width workpieces, make pairs of wedges for each of the following widths: 6 in., 9 in., 12 in. and 18 in. For cutting widths wider than 18 in., you can use more than one pair of wedges.

From Fine Woodworking #97

For the full article, download the PDF below:

Fine Woodworking Recommended Products

JessEm Mite-R Excel II Miter Gauge

Fein Turbo II HEPA Wet/Dry Dust Extractor

Festool Rotex FEQ-Plus Random Orbital Sander

Log in or create an account to post a comment.

Sign up Log in