A Woodworker’s Guide to Medium-Density Fiberboard

Get the most from its glass-flat surfaces and razor-sharp edges

Synopsis: Because of its dense, uniform composition and flatness, MDF has surpassed plywood and particleboard as the sheet good of choice for fine work and more routine uses. Jim Hayden explains this industrial product and its history in detail and then shares tricks and tips on using it — how to machine join and glue it; which hardware and fasteners to use; how to laminate, veneer, and finish it; and how to find and buy it.

Medium-density fiberboard, or MDF as it is more commonly known, is the newest of the furniture-quality wood composites. Because of its dense, uniform composition and flatness, it has surpassed plywood and particleboard as the sheet good of choice for fine work and more routine uses.

Pre-finished faces are flat as the slate on a pool table, which along with its dimensional stability makes it an excellent substrate for veneer. The edges machine well, with no chipout, and MDF accepts a full range of joinery and fasteners.

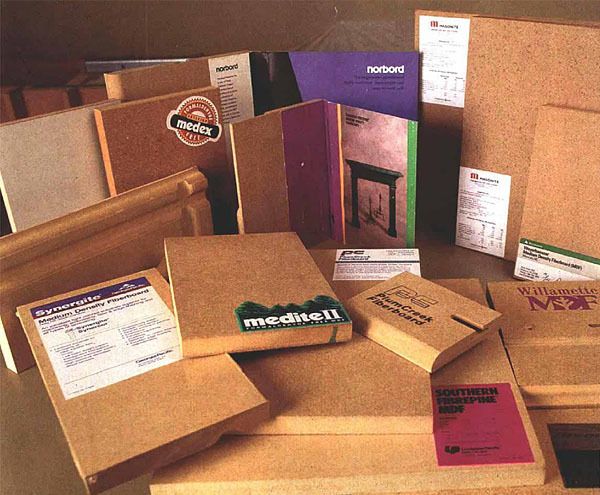

But if you have never seen a 4×8 or 5×8 sheet of MDF or have never even heard of MDF, you have plenty of company. MDF has been an industrial product for its entire 28-year history, with most shipments earmarked for furniture factories and cabinet producers. Only recently has it become more available to retail consumers and small shops. Once you have some MDF in your shop, you may find, as I have, that it is also good stuff to make some of your jigs, fixtures and templates.

Whether you use it for jigs or the substrate for fine veneered furniture, there are some special tricks and tips for using MDF. I’ll share what I’ve learned from my own experience and from research done for the National Particleboard Association (NPA), which includes eight of the nide MDF companies, as well as from the reactions of woodworkers who regularly use MDF in the cabinet shop of the Arthur M. Sackler and Freer Galleries in the Smithsonian Institution.

Machining MDF

Because it’s homogeneous, MDF machines better than plywood or particleboard, and even some natural woods. There are no layers or chips, brittle edges, knots or grain. I routed all 15 types of MDF made in the United States, courtesy of the nine MDF companies. The boards share a sameness in meeting industry standards: They match in density and superb flatness. They differ because the trees harvested near the plants differ. The wood chips, shavings and sawdust (or residuals) from the local sawmills and plywood mills are the raw material of MDF. Also, the companies use proprietary formulas, thus adding a few minor, and in some cases, a few major differences, such as formaldehyde content.

From Fine Woodworking #104

Fine Woodworking Recommended Products

DeWalt 735X Planer

AnchorSeal Log and Lumber End-Grain Sealer

Ridgid R4331 Planer

Log in or create an account to post a comment.

Sign up Log in