Dovetailing Large Carcases

Dedicated bench and clamping system simplify and square the work

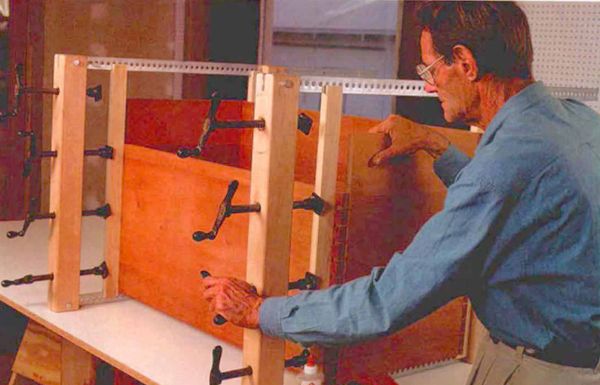

Synopsis: Accurately fitted and squared dovetail corners are crucial to the success of large projects. Here, Charles Durham Jr. details the problems that beset furniture makers and explains how a dedicated dovetailer’s bench helps him overcome the warp on wide boards, allowing him to dovetail the largest boards with ease and precision. A detailed project plan shows the bench’s dimensions and parts, and Durham explains a carcase press saves time and effort over clamping.

I made my first dovetailed carcase with wide pine boards salvaged from the original kitchen in my first house. Dry, flat and wide, those boards became a wonderful blanket chest. Since then, much of the lumber I’ve used on large-carcase projects has been less than ideal. Wide, flat and dry are more the exceptions than the rule, whether you use naturally wide boards or glue narrower stock to width. When wide boards are cupped, twisted or both—even a little—making dovetails that fit well is tough. Yet accurately fitted and squared dovetail corners are crucial to the success of large projects like blanket chests, highboy tops and slant-front desks.

The other problem with large-carcase projects is the glue-up. Even if you’ve cut good, accurate dovetails, gluing and clamping big boards can be a real headache or, worse, result in a flawed project—especially if you work alone, as I usually do. Having the pipe clamp I just tightened fall off and dent the carcase as I tighten the next clamp is just one more hassle than I need.

I solved both problems by building two assemblies: a dovetailer’s bench to hold the boards flat, secure and indexed for accurate layout and cutting (see the drawing on the facing page and the photos on p. 52) and a carcase-press clamping system to help me close wide joints with uniform pressure, without having to wrestle an armload of clamps (see the photo above). Material for both is available at any good lumberyard, and you’ll find all the hardware you need either at your local hardware store or through mail order. Total cost for materials was about $300, with lumber being the most expensive item. By substituting construction lumber for the hard maple I used, you could halve that amount.

Dovetailer’s bench

The problem with laying out and cutting dovetails on a typical cabinetmaker’s bench is that most benches are about 32 in. off the floor, which constrains you to narrower carcase work. To do bigger jobs on an ordinary bench, you have to jury-rig a support and clamp system to hold things flat and steady at the right height while you mark, saw and chop. My bench is a large, elevated clamping device that lets me overcome warp on wide boards, allowing me to dovetail the largest boards with ease and precision.

From Fine Woodworking #105

Fine Woodworking Recommended Products

Dubuque Clamp Works Bar Clamps - 4 pack

Milescraft 4007 6in Bench Clamp

Festool DF 500 Q-Set Domino Joiner

Log in or create an account to post a comment.

Sign up Log in