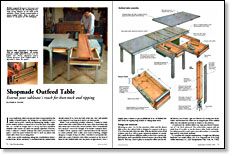

Shopmade Outfeed Table

Extend your tablesaw's reach for sheet stock and ripping

Synopsis: Frank A. Vucolo used 150-lb.-capacity drawer slides in building a retractable extension table for his tablesaw, so now he just opens a drawer to get 24 in. more outfeed surface. He shares his design and the materials he used, and then explains how he made and mounted the table. It’s critical that the rollers are mounted at the correct height, and he explains how to do that. A detailed project plan gives the essential construction details.

In my small shop, ideal concepts are often compromised by the reality of limited space. My design for an outfeed table is a classic case in point. I started out thinking big. Ideally, I wanted the outfeed surface to extend 48 in. from the back of my tablesaw, so I would no longer have to set up and then reposition unstable roller stands. My ideal was quickly squashed, however, when I realized I couldn’t dedicate that much permanent floor space. I need the space behind the saw to store my planer and router table when I’m not using them.

After some careful measuring, taking into consideration where I would locate all the machines, I concluded that the outfeed table should extend 30 in. from the back of the saw. But I still needed more support to rip long stock and to cut sheet goods.

While I was pondering possible solutions, I started to think about rollers that could extend off the back of the fixed table and then retract into it when they weren’t needed. Then I remembered how amazed I was at the strength of Accuride’s extension drawer slides (150-lb. capacity) when I had used them for file drawers in a desk pedestal. After a little more head scratching, nudged along by a couple of cups of coffee, I decided to incorporate the slides into a pair of drawers with rollers mounted on the front of them for the outfeed table (see the photo at right above). Now I simply open a drawer to get an additional 24 in. of outfeed surface when I’m ripping long boards or cutting sheet stock.

Design and materials

Allowing an extra 1 in. for the extension rollers and the drawer slide action, the outfeed table is designed to support work up to 55 in. from the back of the saw table. With the drawers in the closed position, only 30 in. of floor space behind the tablesaw is committed. I made the drawers different widths so that I have various outfeed options, and I extended the drawer bottoms out in front of the drawers. This way, I have a place to mount the rollers (see the detail above). As a bonus, I get two drawers for storing saw accessories. And because the rollers are an integral part of the outfeed table, they are adjusted precisely in relation to the tabletop.

I constructed the outfeed table’s top, legs and drawer bottoms out of -in. birch plywood. The under-table support rails are made from 4/4 poplar, as are the drawer sides, fronts and backs. For added protection and to give a nice slick surface, I covered the legs and top with plastic laminate.

From Fine Woodworking #108

For the full article, download the PDF below:

Fine Woodworking Recommended Products

WoodRiver Router Bit Storage Case

Woodriver Circle Cutting Jig

Incra Miter 1000HD

Log in or create an account to post a comment.

Sign up Log in