A Stop for Every Jig

Simple, versatile stops are crucial to accurate machining

Synopsis: Woodworkers can regulate the length and width of parts and the depth of grooves and holes by using stops on jigs and in conjunction with tools, writes Sandor Nagyszalanczy. Regulating the distance between the end of a part and the point where it’s cut to length or machined is a basic function of stop devices. Nagyszalanczy explains why production shops can’t do without stops and describes som shop mainstays: length stops, adjustable flip-down stops, eccentric end stops, and rotating stops. Detailed drawings illustrate his explanations, and side information covers cursors and stick-on metal rules, as well as making a T-slot track.

Most things that we do in our everyday lives have limits: the maximum speed you’re supposed to travel on the highway; the minimum age you must be to buy a bottle of liquor; the most books you can check out of a library at one time. The world of woodworking is no different, except we call the limits measurements. We strive to maintain the exactness of measurements to make parts fit more precisely together, so the joinery will be strong and look clean. Some measurements are set on our machines, such as the depth of cut of a tablesaw or handplane, and some must be regulated by eye, as when chiseling down to a pencil line. But we regulate a great many limits—measurements for the length or width of parts, depth of grooves and holes—by using stops on our jigs and in conjunction with our tools.

Regulating the distance between the end of a part and the point where it’s cut to length or machined is a basic function of stop devices. As with other types of jigs and shopmade setups, there are many different kinds of stops to choose from, each appropriate for a particular range of tools and applications. The simplest stops are merely wooden blocks, clamped or screwed to the machine, jig or the work itself. More ingenious stops revolve to adjust or change position. The right stop can increase the accuracy of an operation, as well as save time when making repeat cuts because parts need not be marked individually. This is why production shops can’t do without the use of stops.

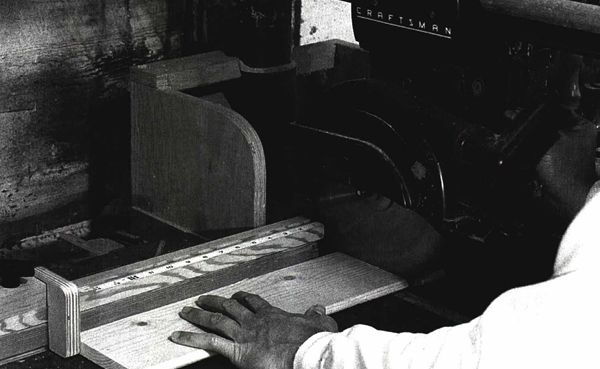

Length stops

Length stops are used mostly for crosscutting or shaping across the width of stock, but they are easily adapted to work with other machines in a variety of applications. Length stops are commonly used on tablesaws, radial-arm saws, sliding-compoundmiter saws and both powered miter saws and nonpowered (handsaw) miter boxes. Length stops are also welcome additions to fences used with miter gauges, drill presses, mortising machines, sliding crosscut boxes and other sliding carriage jigs.

From Fine Woodworking #109

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Ridgid EB4424 Oscillating Spindle/Belt Sander

Incra Miter 1000HD

Stanley Powerlock 16-ft. tape measure

Log in or create an account to post a comment.

Sign up Log in